Preparation method for salvianolic acid A

A technology of salvianolic acid and salvianolic acid salt, which is applied in the field of preparation of salvianolic acid A, can solve the problems of inability to meet the needs of industrialization, low yield of salvianolic acid A, difficult product separation, etc., and achieve convenient control of the degradation process , The effect of small product changes between batches and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1. prepares salvianolic acid A conversion liquid

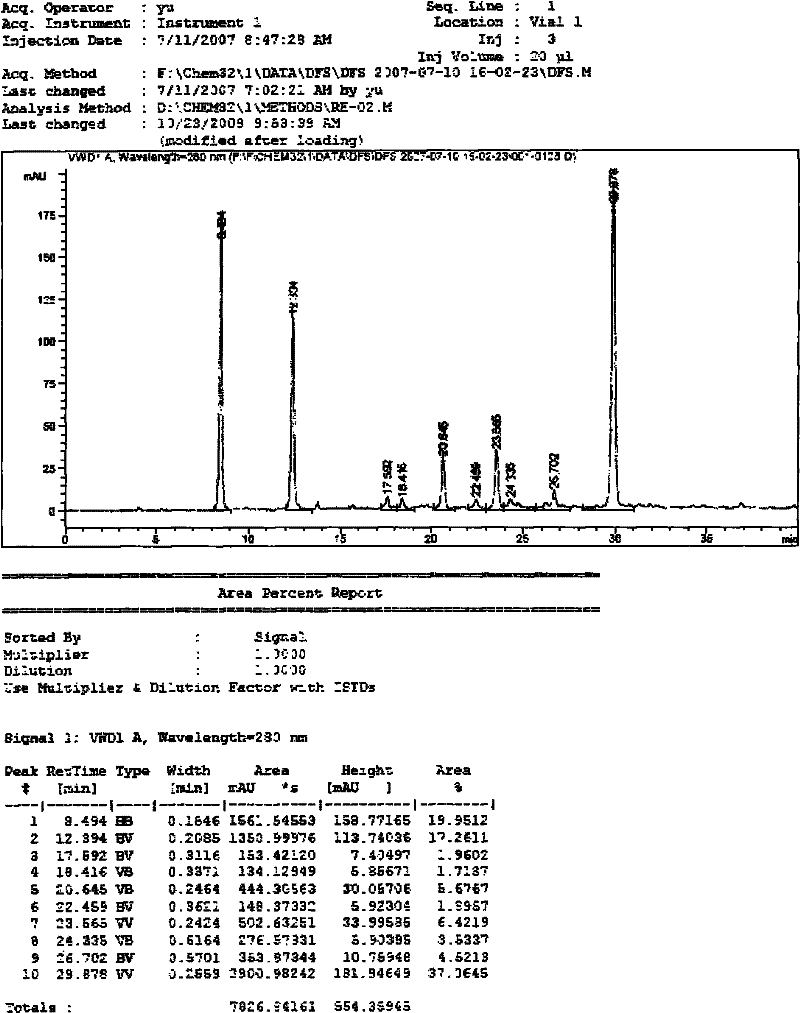

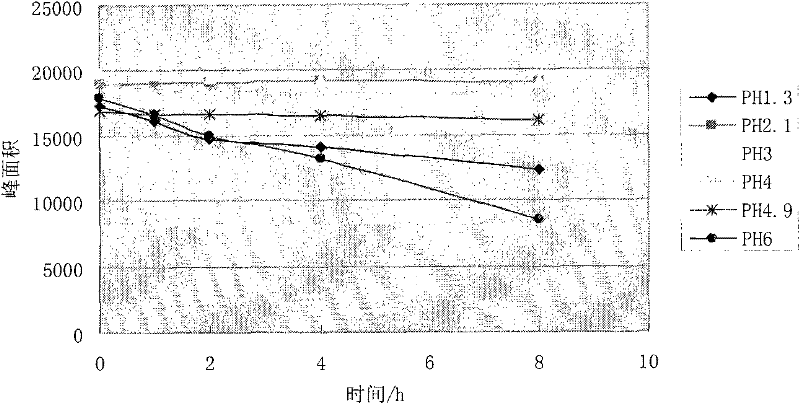

[0022] Take 12g of salvianolic acid salt (the content is greater than 80% based on the magnesium acetate of salvia miltiorrhiza), add 1L of water, adjust the pH value to 6.0 with trisodium citrate, put it in an autoclave, heat at 125°C and 0.15MPa for 4 hours , after solution cooling, add hydrochloric acid and adjust pH value to 2~3, obtain salvianolic acid A conversion liquid; The HPLC analysis of conversion liquid shows, the molar conversion rate of salvianolic acid A 45% ( figure 1 ).

Embodiment 2

[0023] Embodiment 2. prepare salvianolic acid A

[0024] Take the conversion solution of the salvianolic acid A conversion solution of Example 1 and pass through the HPD100 resin column, and then eluted with water for 10 column volumes, 25% ethanol solution for 8 column volumes, discarded, and then 40% ethanol solution for 10 column volumes. column volume, collect the eluent 1, concentrate the eluate 1 under reduced pressure to a salvianolic acid A concentration of 25 mg / ml, pass the concentrated solution through a CG161 resin column, elute with 20% ethanol solution for 10 column volumes, and discard it. Then eluted with 35% ethanol solution for 12 column volumes, collected the eluate 2, concentrated under reduced pressure to a salvianolic acid A concentration of 50 mg / ml; adjusted the pH to 2-3 with hydrochloric acid, extracted three times with an equal volume of ethyl acetate, and combined Concentrate the extract under reduced pressure, add 2.5 times the amount of 80-120 mes...

Embodiment 3

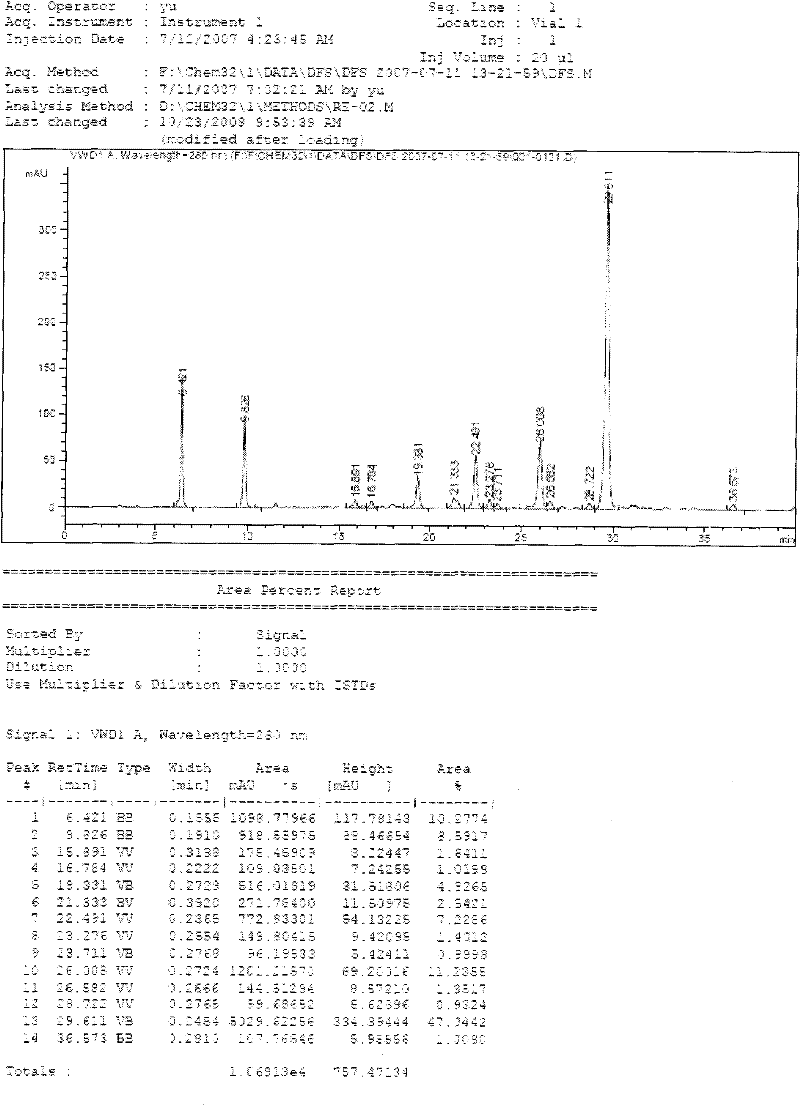

[0025] Embodiment 3. prepare salvianolic acid A conversion liquid

[0026] Take 10g of salvia miltiorrhiza magnesium acetate, add 1L of water, add 10ml of ethyl acetate, adjust the pH value of the solution to 6, put it in an autoclave at 125°C, 0.15MPa, heat for 4 hours, after the solution is cooled, add hydrochloric acid to adjust the pH value From 2 to 3, the conversion solution of salvianolic acid A is obtained, and the HPLC analysis of the conversion solution shows that the molar conversion rate of salvianolic acid A is 72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com