Method for preparing nano-fibers with special structures by using electrostatic spinning

A nanofiber, electrospinning technology, applied in fiber processing, fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of difficult operation, high cost, complicated post-processing process, etc., and achieve simple experimental equipment, easy operation and wide range of The effect of suitability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

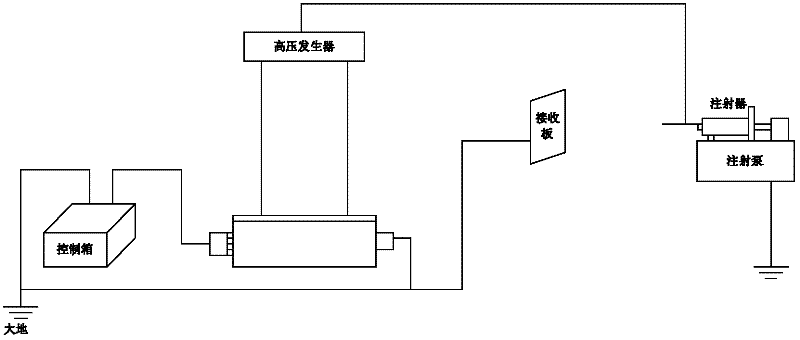

[0026] 1. Preparation of electrospinning precursor solution: configure polymer (PVP (polyvinylpyrrolidone), PMMA (polymethyl methacrylate), PAN (polyacrylonitrile), etc.) with a mass fraction of 1-20% solution, static Spinning is carried out after removing air bubbles.

[0027] 2. Electrospinning steps: Put the precursor solution configured in the above steps into the syringe, adjust the voltage of the high voltage generator to 5-50kV, set the receiving distance (the distance between the nozzle and the receiver) to 5-25 cm, and then start spinning Silk, and finally collected ultrafine nanofibers.

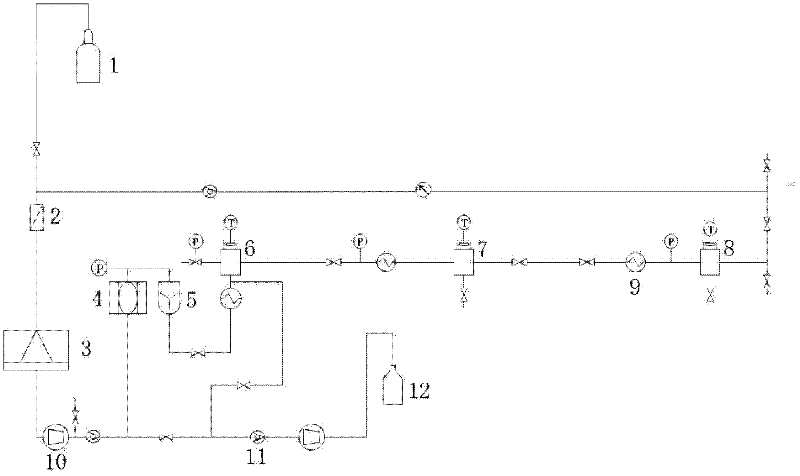

[0028] The ultrafine nanofibers prepared in the above steps are put into a separation kettle of a supercritical extraction device, and the nanofibers are foamed by a supercritical carbon dioxide rapid depressurization method. The foaming pressure is set at 4-20Mpa, the temperature is set at 50-100°C, and the soaking time is set at 5-60min. In the nanofiber, the supersaturated carb...

Embodiment 1

[0030] (1) Dissolve PMMA (polymethyl methacrylate) in ethyl acetate, stir for 4 hours to form a polymer solution with a mass fraction of 7%, and let stand to remove air bubbles.

[0031] (2) Add the polymer solution prepared in step 1 into the syringe, adjust the voltage to 18kV, set the receiving distance to 10cm, and set the flow rate of the syringe pump to 0.02mL / min. Turn on the spinning device to spin and collect PMMA (polymethyl methacrylate) ultrafine nanofibers.

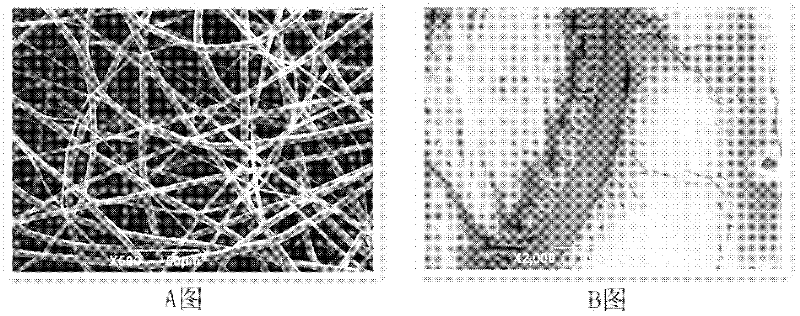

[0032] (3) Put the ultra-fine nanofibers prepared in the above steps into the separation kettle of the supercritical extraction device, and use supercritical carbon dioxide to quickly reduce the pressure under the conditions of a pressure of 8Mpa, a temperature of 80°C, and a soaking time of 10min. By foaming the nanofibers, PMMA (polymethyl methacrylate) ultrafine nanofibers with a wrinkled structure can be obtained.

Embodiment 2

[0034] (1) Dissolve PMMA (polymethyl methacrylate) in ethyl acetate, stir for 4 hours to form a polymer solution with a mass fraction of 7%, and let stand to remove air bubbles.

[0035] (2) Add the polymer solution prepared in step 1 into the syringe, adjust the voltage to 20kV, set the receiving distance to 15cm, and set the flow rate of the syringe pump to 0.02mL / min. Turn on the spinning device to spin and collect PMMA (polymethyl methacrylate) ultrafine nanofibers.

[0036] (3) Put the ultra-fine nanofibers prepared in the above steps into the separation kettle of the supercritical extraction device, and use supercritical carbon dioxide to quickly reduce the pressure under the conditions of 6Mpa pressure, 80°C temperature and 10min soaking time By foaming the nanofibers, PMMA (polymethyl methacrylate) ultrafine nanofibers with a wrinkled structure can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com