Bearing for copper-based heavy-load self-lubricating ship and preparation method thereof

A self-lubricating, marine technology, used in bearing components, shafts and bearings, mechanical equipment, etc., to solve problems such as poor tensile strength of sliding bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

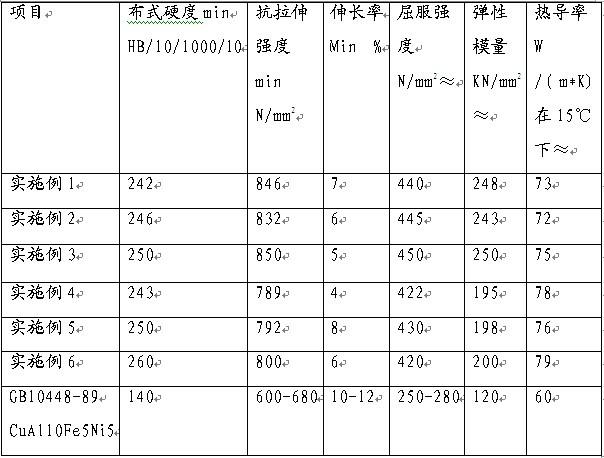

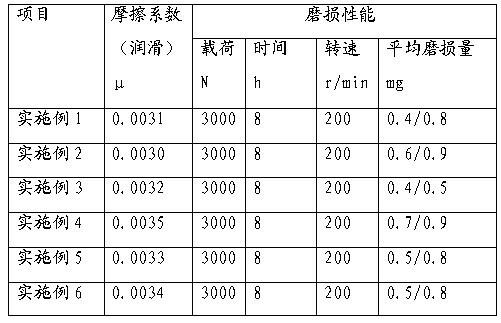

Examples

Embodiment 1

[0062] Example 1: A copper-based heavy-duty self-lubricating marine bearing, including a steel back and an anti-friction structure integrally connected with the steel back. The anti-friction structure is prepared from the following materials in parts by weight: 9 parts of nickel-plated graphite, 0.1 90.5 parts of aluminum bronze alloy; the composition of the aluminum bronze alloy is as follows: 72 parts of copper, 12.8 parts of aluminum, 4.6 parts of iron, 0.08 parts of manganese, 6.0 parts of nickel, 0.042 parts of lead, and 0.3 parts of zinc.

[0063] The rare earth is cerium or lanthanum or praseodymium or neodymium or a mixture of two of them or a mixture of three of them or a mixture of these four; the rare earth in this embodiment is composed of materials with the following mass ratio: 65% cerium, 33% lanthanum , 1% neodymium, 1% praseodymium.

[0064] The method for manufacturing the above-mentioned copper-based heavy-duty self-lubricating marine bearing comprises the f...

Embodiment 2

[0078] Example 2: A copper-based heavy-duty self-lubricating marine bearing, including a steel back and an anti-friction structure integrally connected with the steel back. The anti-friction structure is prepared from the following materials in parts by weight: 15 parts of nickel-plated graphite, 0.3 91.5 parts of aluminum bronze alloy; the composition of the aluminum bronze alloy is as follows: 90 parts of copper, 13.6 parts of aluminum, 7.2 parts of iron, 0.09 parts of manganese, 7.4 parts of nickel, 0.049 parts of lead, and 0.49 parts of zinc.

[0079] The rare earth is cerium or lanthanum or praseodymium or neodymium or a mixture of two of them or a mixture of three of them or a mixture of these four; the rare earth of this embodiment is composed of materials with the following mass ratio: 70% cerium, 28% lanthanum , 1% neodymium, 1% praseodymium.

[0080] The method for manufacturing the above-mentioned copper-based heavy-duty self-lubricating marine bearing comprises the...

Embodiment 3

[0094] Example 3: A copper-based heavy-duty self-lubricating marine bearing, including a steel back and an anti-friction structure integrally connected with the steel back. The anti-friction structure is prepared from the following materials in parts by weight: 13 parts of nickel-plated graphite, 0.2 Rare earth, 91 parts of aluminum bronze alloy; the composition of the aluminum bronze alloy is as follows: 80 parts of copper, 13.4 parts of aluminum, 5.8 parts of iron, 0.08 parts of manganese, 7.0 parts of nickel, 0.045 parts of lead, and 0.45 parts of zinc.

[0095] The rare earth is cerium or lanthanum or praseodymium or neodymium or a mixture of two of them or a mixture of three of them or a mixture of these four; the rare earth in this embodiment is composed of materials with the following mass ratio: 68% cerium, 31% lanthanum , 0.5% neodymium, 0.5% praseodymium.

[0096] The method for manufacturing the above-mentioned copper-based heavy-duty self-lubricating marine bearing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com