Method for making liquid crystal display element, liquid crystal display element, and polymer composite

A technology for liquid crystal display elements and manufacturing methods, which are applied to the photoengraving process of the pattern surface, the photosensitive materials used for opto-mechanical equipment, optics, etc., can solve the problem of worrying about the display properties, voltage retention properties, and no reactive mesogens are recorded. , UV radiation and other problems, to achieve the effect of excellent display properties, sufficient light transmittance and contrast, and wide viewing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example A-1

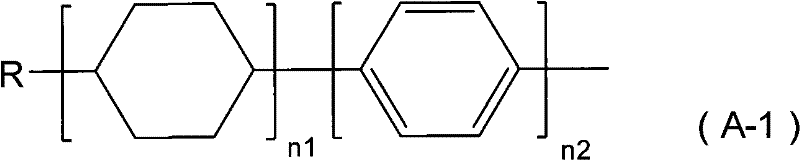

[0309] Synthesis Example A-1 (Synthesis Example according to Production Method 1)

[0310] In a reaction vessel equipped with a stirrer, a thermometer, a dropping funnel, and a reflux condenser, 11.3 g of oxalic acid and 24.2 g of ethanol were added and stirred to prepare an ethanol solution of oxalic acid. Next, after heating this solution to 70 degreeC in nitrogen atmosphere, the mixture which consists of 12.3 g of tetraethoxysilanes and 2.2 g of dodecyltriethoxysilanes was added dropwise thereto as a silane compound. After completion of the dropwise addition, the temperature of 70° C. was maintained for 6 hours, and then cooled to 25° C., and then 40.0 g of butyl cellosolve was added to prepare a solution containing polyorganosiloxane (A-1).

[0311] The weight average molecular weight Mw of the polyorganosiloxane (A-1) contained in this solution was 12,000.

Synthetic example A-2

[0312] Synthesis Example A-2 (Synthesis Example according to Production Method 2)

[0313] In the reaction solution with stirrer, thermometer, dropping funnel and reflux condenser, add 45.2g propylene glycol monomethyl ether and 18.8g tetraethoxysilane, 3.3g dodecyl triethoxysilane, will It is stirred to prepare a mixed solution of the silane compound. Next, after heating this solution to 60 degreeC, the oxalic-acid solution which consists of 8.8 g of water and 0.1 g of oxalic acid was dripped there. After completion of the dropwise addition, the solution was heated at a solution temperature of 90° C. for 3 hours, and then cooled to room temperature. Next, 76.2 g of butyl cellosolves were added thereto to prepare a solution containing polyorganosiloxane (A-2).

[0314] The weight average molecular weight Mw of the polyorganosiloxane (A-2) contained in this solution was 11,000.

Synthetic example A-3

[0315] Synthesis Example A-3 (Synthesis Example according to Production Method 4)

[0316] [Hydrolysis and condensation reactions of silane compounds]

[0317] In a reaction vessel with a stirrer, a thermometer, a dropping funnel and a reflux condenser, add 246.4 g of 2-(3,4-epoxycyclohexyl)ethyltrimethoxysilane (ECETS) as a silane compound, 1,000 g of methyl isobutyl ketone as a solvent and 10.0 g of triethylamine as a catalyst were mixed at room temperature. Next, after adding 200 g of deionized water dropwise thereto from the dropping funnel over 30 minutes, it was reacted at 80° C. for 6 hours while stirring under reflux. After the reaction was finished, the organic layer was taken out, washed with 0.2% by weight of ammonium nitrate aqueous solution until the water after washing was neutral, and the solvent and water were distilled off under reduced pressure to obtain polyorganosiloxane with epoxy groups. THICK TRANSPARENT LIQUID.

[0318] The polyorganosiloxane 1 In H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com