Advanced process control system and test method thereof

A technology of advanced process control and process control module, applied in general control system, control/regulation system, adaptive control, etc., can solve the problems of accelerating system development, difficult testing and verification, and reducing system development cost, etc., to achieve easier Effects of reproducibility, lower testing and validation costs, and shorter development cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

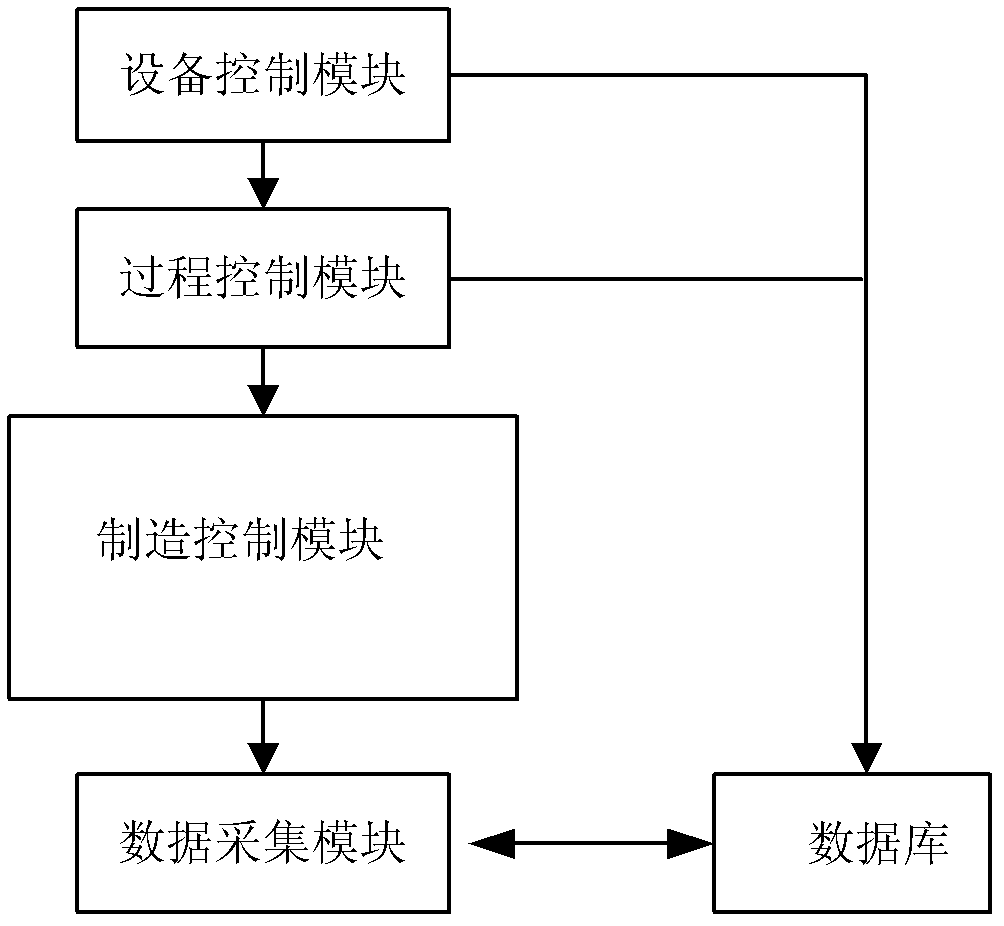

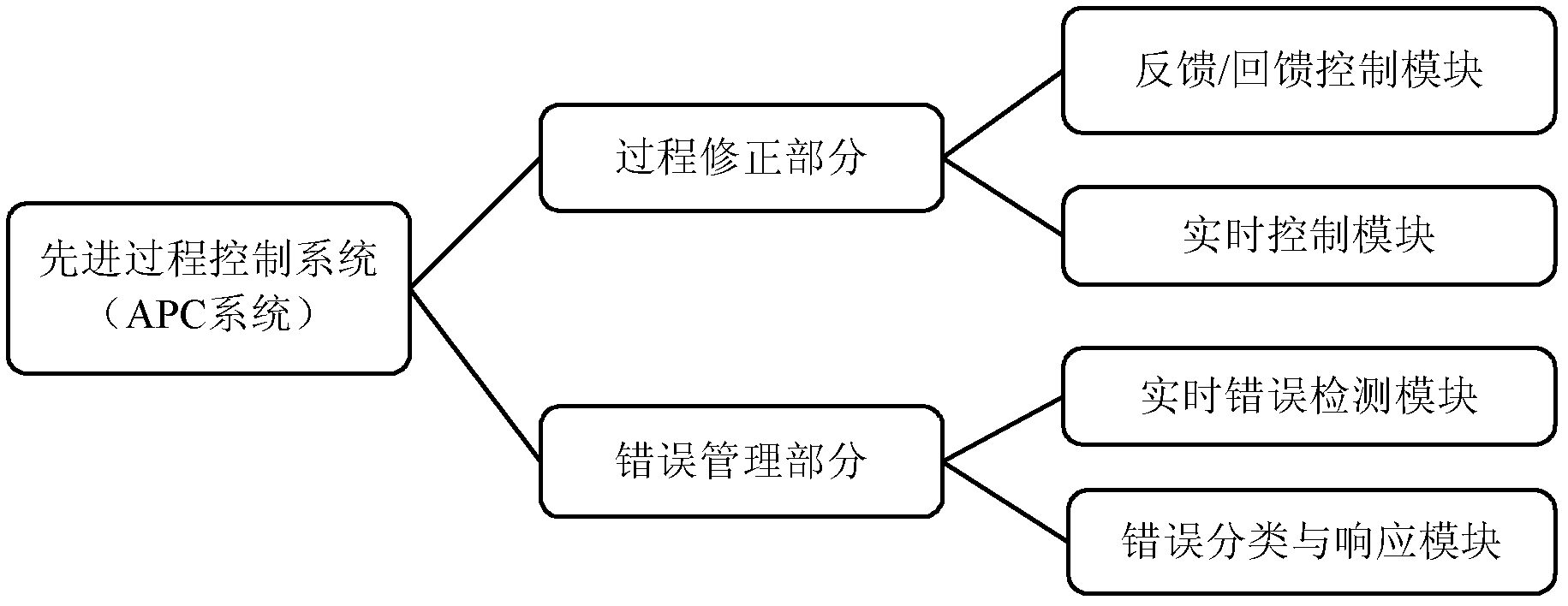

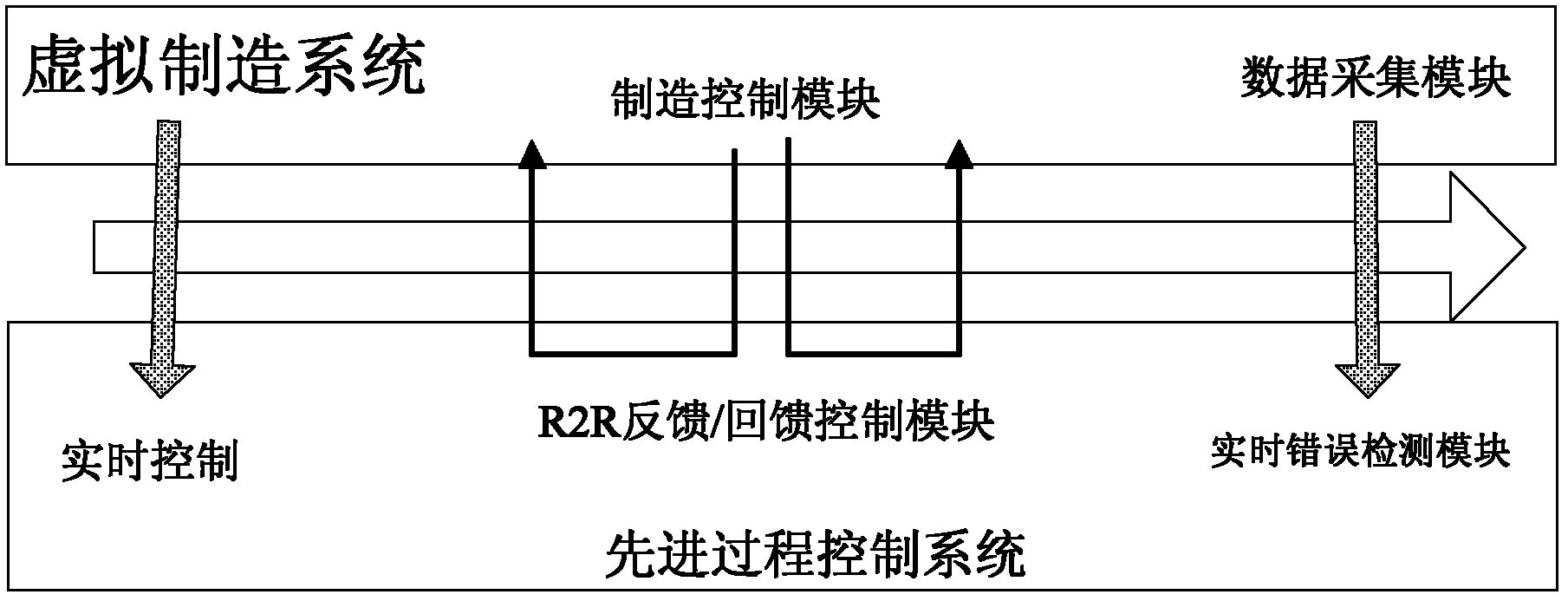

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. While illustrations of parameters including particular values may be provided herein, it should be understood that parameters need not be exactly equal to the corresponding values, but rather may approximate the values within acceptable error margins or design constraints.

[0020] Virtual Manufacturing Fab (Virtual Manufacturing Fab, referred to as: Virtual Fab) is a technology that simulates and predicts possible problems in various aspects such as product function, performance and manufacturability through computer virtual models. Before the product is actually produced, first generate a soft product prototype (Soft Prototype) in the virtual manufacturing environment instead of the traditional hard sample (Hard Protot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com