Hot disc and silicon chip heating system applying same

A heating system and silicon wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as bending deformation, inclination of silicon wafer 12, affecting line width uniformity, etc., to avoid pollution, heat evenly, Avoid the effect of bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

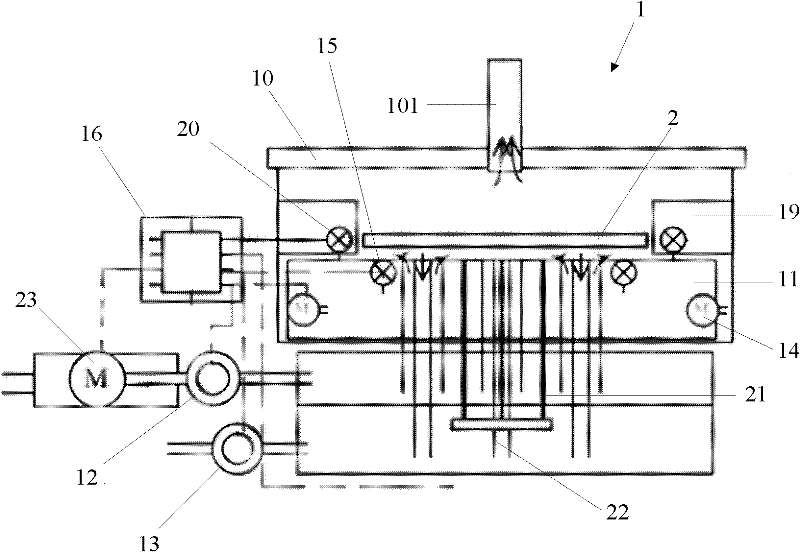

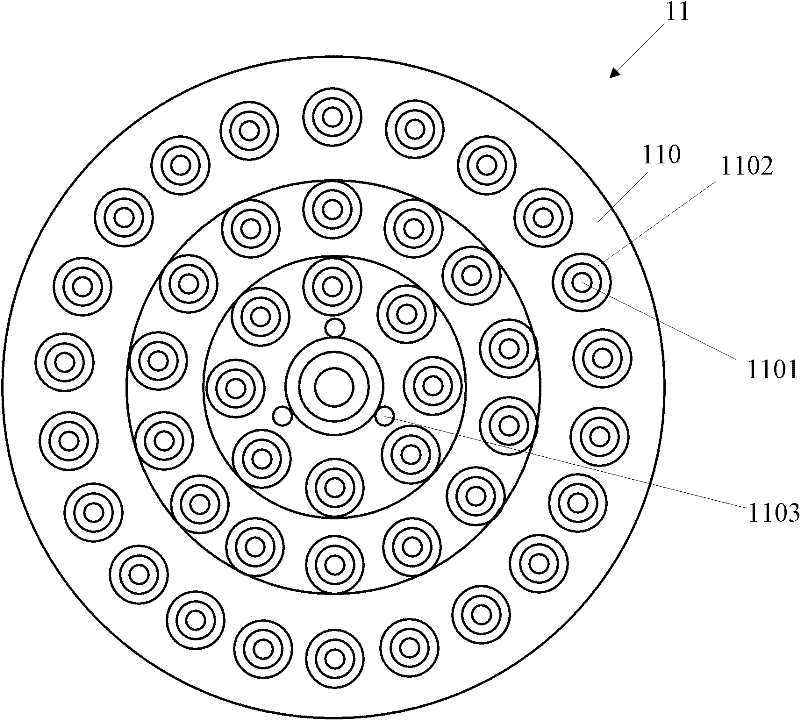

[0030] figure 2 It is a schematic diagram of a silicon wafer heating system according to a preferred embodiment of the present invention. image 3 It is a top view of a heat plate according to a preferred embodiment of the present invention. Please refer to figure 2 and image 3 . In this embodiment, the silicon wafer heating system 1 is used to heat the silicon wafer 2, which includes a housing body 10, a heating plate 11, an air intake fan 12, an exhaust fan 13, a first heating device 14, a first temperature detection device 15, A temperature controller 16 , a second temperature detection device (not shown), an automatic pressure regulating valve (not shown), a silicon chip protection device 19 , a position sensor 20 , a push rod 21 , a driving device 22 and a second heating device 23 . However, the present invention does not make any limitation thereto.

[0031] In this embodiment, the accommodating body 10 is the furnace body of the silicon wafer heating system 1 , ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap