Semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, which are applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device parts, etc., can solve the problems of contamination, chemical reagent damage, affecting the dielectric constant of the first dielectric layer 110, and the like, Achieve the effect of avoiding metal contamination and preventing changes in dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

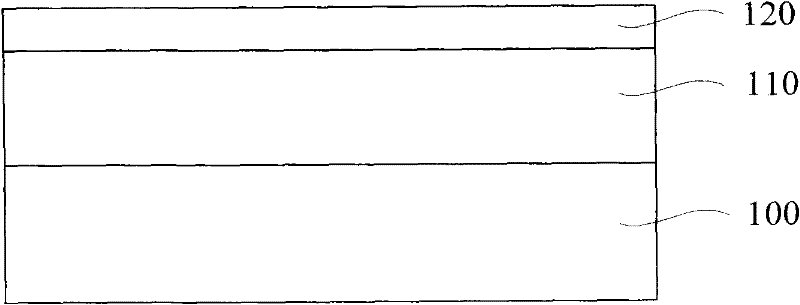

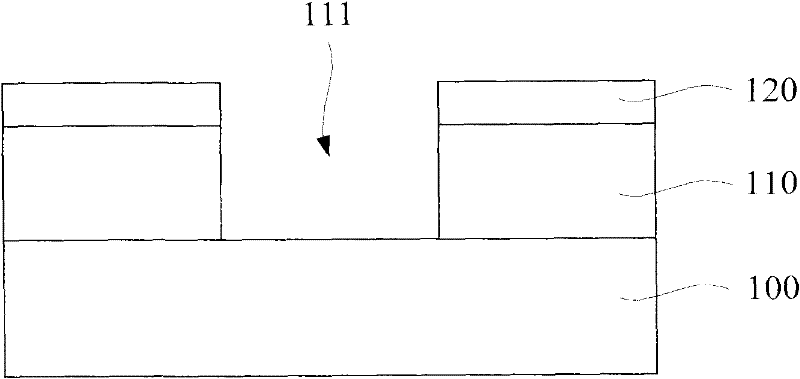

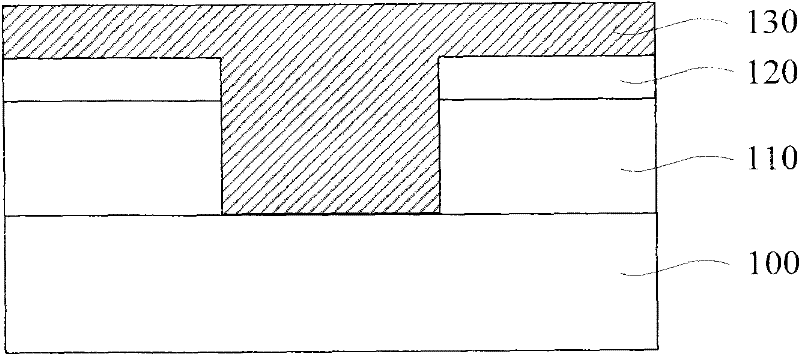

[0031] As mentioned in the background art, when the chemical mechanical polishing process is performed, the polishing liquid used will cause the dielectric constant of the first dielectric layer to change, which will adversely affect the performance of the subsequently formed metal interconnection lines. Therefore, the present invention covers the first barrier layer on the surface of the first dielectric layer, and only removes the first hard mask layer and part of the first metal layer when performing the first chemical mechanical polishing process, while retaining part or all of the The first barrier layer, that is, the surface of the first dielectric layer will not be exposed, therefore, the grinding liquid will not damage the first dielectric layer, which can prevent the dielectric constant of the first dielectric layer from changing; secondly, the first dielectric layer A barrier layer can also prevent the chemical reagent used when forming the first metal cap layer from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com