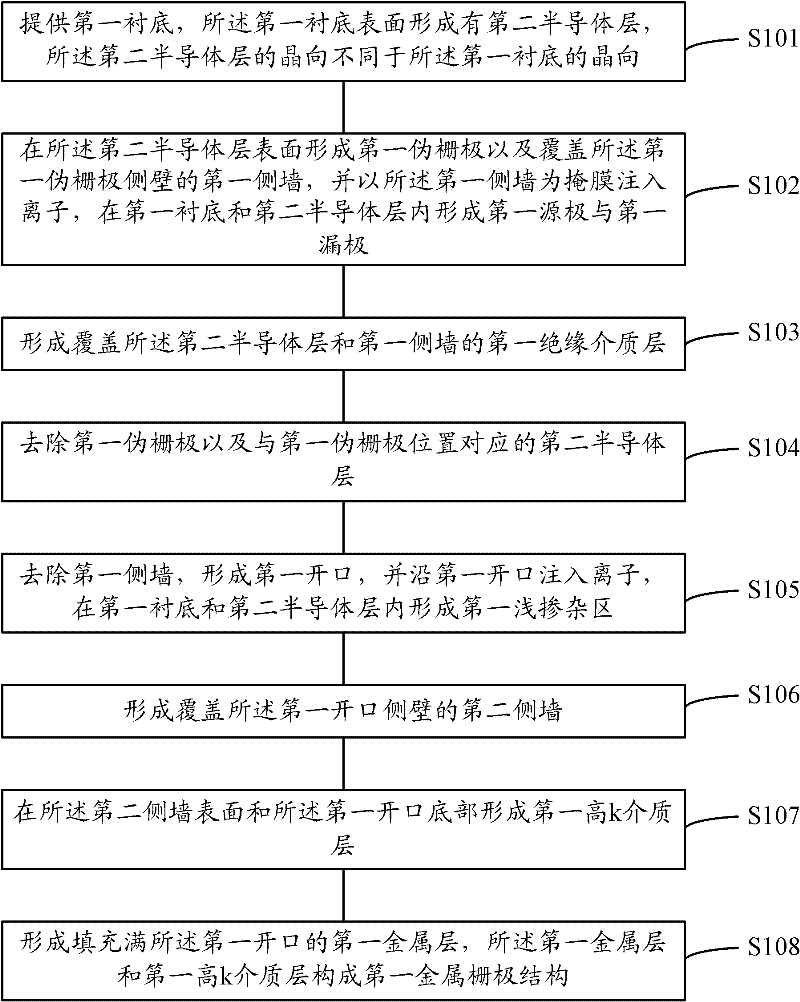

Metal oxide semiconductor device and forming method thereof

A technology of oxide semiconductors and semiconductors, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., to achieve the effects of improving performance, low cost, and improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

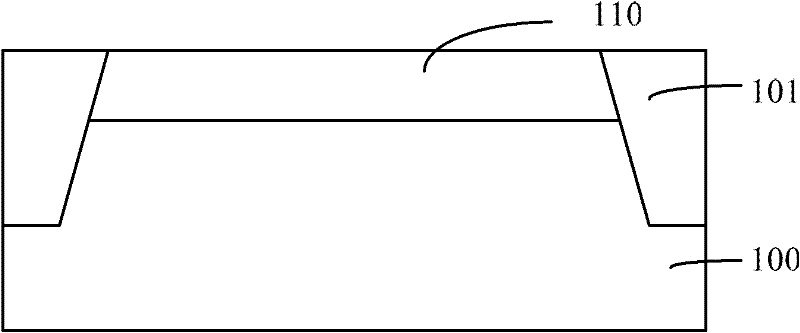

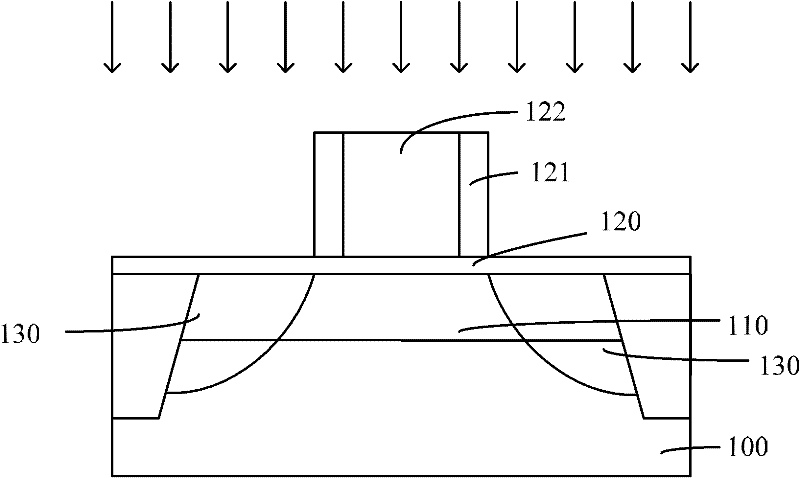

Embodiment Construction

[0077] It can be seen from the background art that the carrier mobility of existing metal oxide semiconductor devices is relatively small. The inventors of the present invention investigated this and found that in the current semiconductor technology, metal oxide semiconductor devices are often fabricated on a semiconductor wafer having a single crystal orientation such as silicon. In particular, most of today's semiconductor devices are fabricated on the surface of silicon wafers with a (100) crystalline orientation. However, electrons have higher mobility in silicon wafers with (100) crystallographic orientation, while holes have higher mobility in silicon wafers with (110) crystallographic orientation. So (110) crystalline silicon wafers are most suitable for PMOS devices, but not for NMOS devices. In contrast, silicon wafers with a (100) crystalline orientation are most suitable for NMOS devices, but not for PMOS devices.

[0078] The inventor also found that stress can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com