Preparation method for lithium ion battery anode active material

A negative electrode active material, lithium-ion battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of poor cycle performance, low battery capacity, complicated preparation process, etc., and achieve the effect of improving capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of lithium ion battery negative electrode active material, comprises the following steps:

[0024] 1) Disperse the acidified graphite evenly in the organic polymer to obtain a mixed system;

[0025] 2) In a stirring state, add a solution containing an organic metal salt to the mixed system; in the organic metal salt solution, the solute contains organic tin and organic cobalt, and the solvent is an organic solvent;

[0026] 3) Sintering at 500-900° C. after drying to obtain the lithium ion battery negative electrode active material.

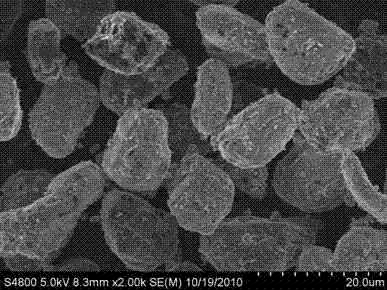

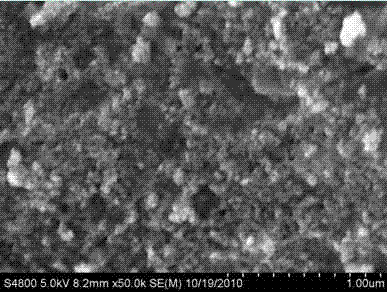

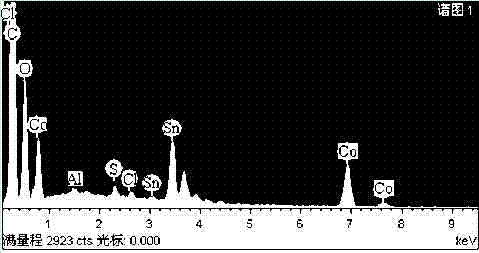

[0027] The negative electrode active material obtained by the preparation method of the invention has a core-shell structure, wherein the inner core is graphite, and the outer shell is tin-cobalt alloy and amorphous carbon. When preparing a negative active material with a core-shell structure in CN101740764A, the tin salt is first mixed with the organic high molecular polymer, and then m...

Embodiment 1

[0040] (1) Blend 2000g of sulfuric acid with a concentration of 98wt% and 120g of graphite, heat to 85°C, stir for 3h, wash and filter the solution, and dry at 60°C for 12h; the mass ratio of acidified graphite 96g to organic polymer P123 is 10:1 mixed evenly to get a mixed system.

[0041] (2) Dissolve 0.12mol of tetrabutyltin chloride and 0.08mol of cobalt acetate in ethylene glycol to prepare 400mL of organometallic salt solution, add the organometallic salt solution to the above mixing system, mix and stir, turn to Into a water bath, the temperature was raised to 80°C and stirred for 6h.

[0042] (3) After the stirring is completed, vacuum bake at 80°C for 12 hours to obtain the pre-product A. The pre-product A was sintered at 600° C. for 12 hours under the protection of argon to obtain the negative electrode active material B.

[0043] (4) According to the mass ratio, the negative electrode active material B: SBR: CMC = 100:6:4 was mixed evenly, and then pressed into ta...

Embodiment 2

[0045] The negative electrode active material C and the battery sample CC were prepared by the same steps as in Example 1, except that in step (3), the pre-product A was sintered at 900° C. for 12 h under the protection of argon to obtain the negative electrode active material C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com