Sodium-doped lithium vanadium fluorophosphate material and preparation method and application thereof

A lithium vanadium phosphate and sodium doping technology, which is applied in the field of materials, can solve the problems of low conductivity and achieve the effects of good crystallization performance, low production cost, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

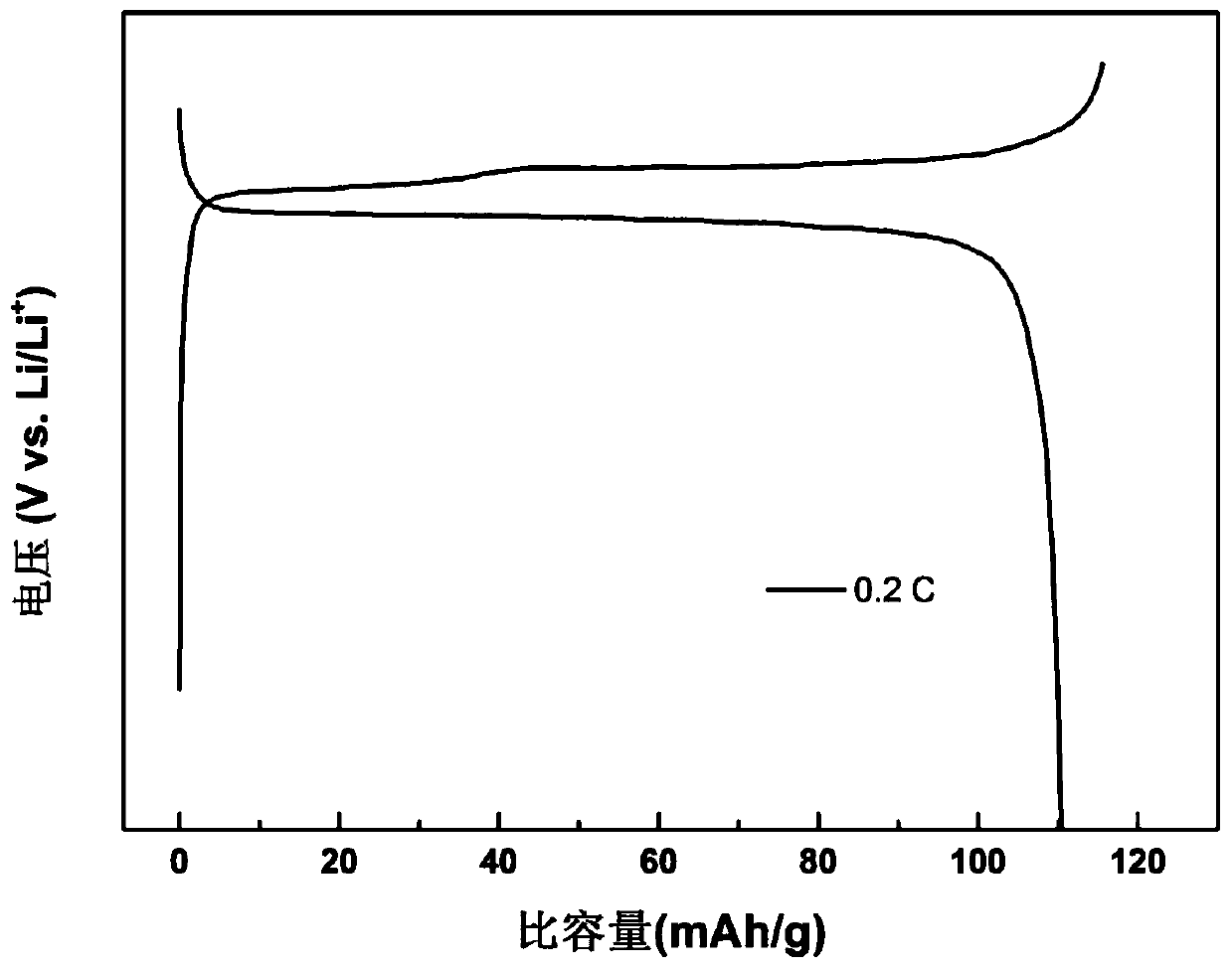

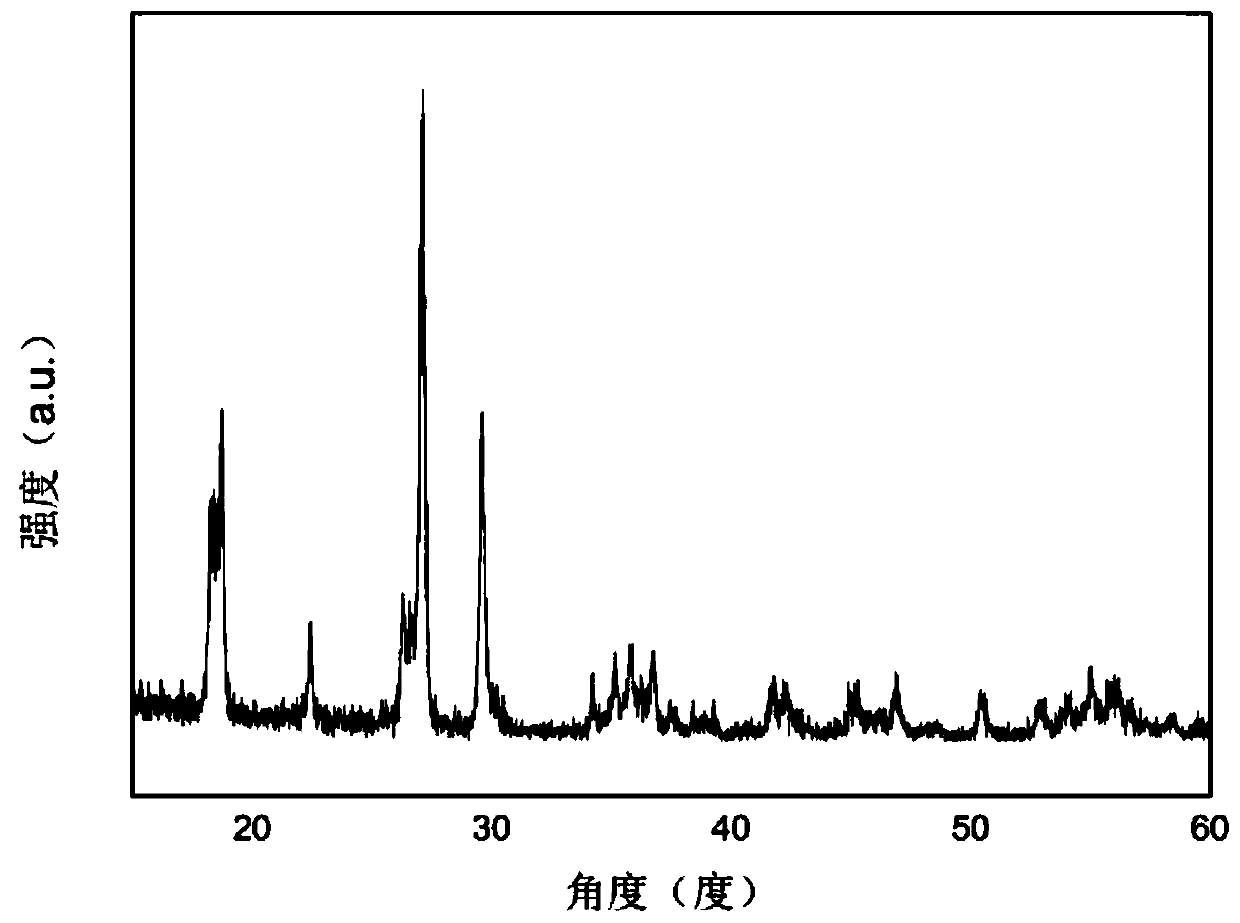

[0035] This embodiment discloses a sodium-doped lithium vanadium phosphate material whose general formula is Li 0.9 / Na 0.1 VPO 4 F.

[0036] The preparation method of the sodium-doped lithium vanadium phosphate material comprises the following steps:

[0037] Mix vanadyl oxalate and ammonium dihydrogen phosphate, then add glucose accounting for 40% of the total mass fraction, mix and stir evenly in a water bath, the temperature of the water bath is 70°C, and the stirring time is 20min. Thick, put into 60 ℃ oven to dry. The dried samples were calcined in a tube furnace filled with argon to obtain VPO 4 / C. Calcination conditions are: 750°C, 10h.

[0038] will VPO 4 / C and LiF dry milled with Na source, VPO 4 The molar ratio of vanadium and lithium elements of / C and LiF is 1:1. The ball milling conditions are: 200r / min, run for 6h, separate the balls and grind them into powder. Among them, sodium sources NaCl, NaOH, CH 3 COONa.

[0039] The powdered samples were cal...

Embodiment 2

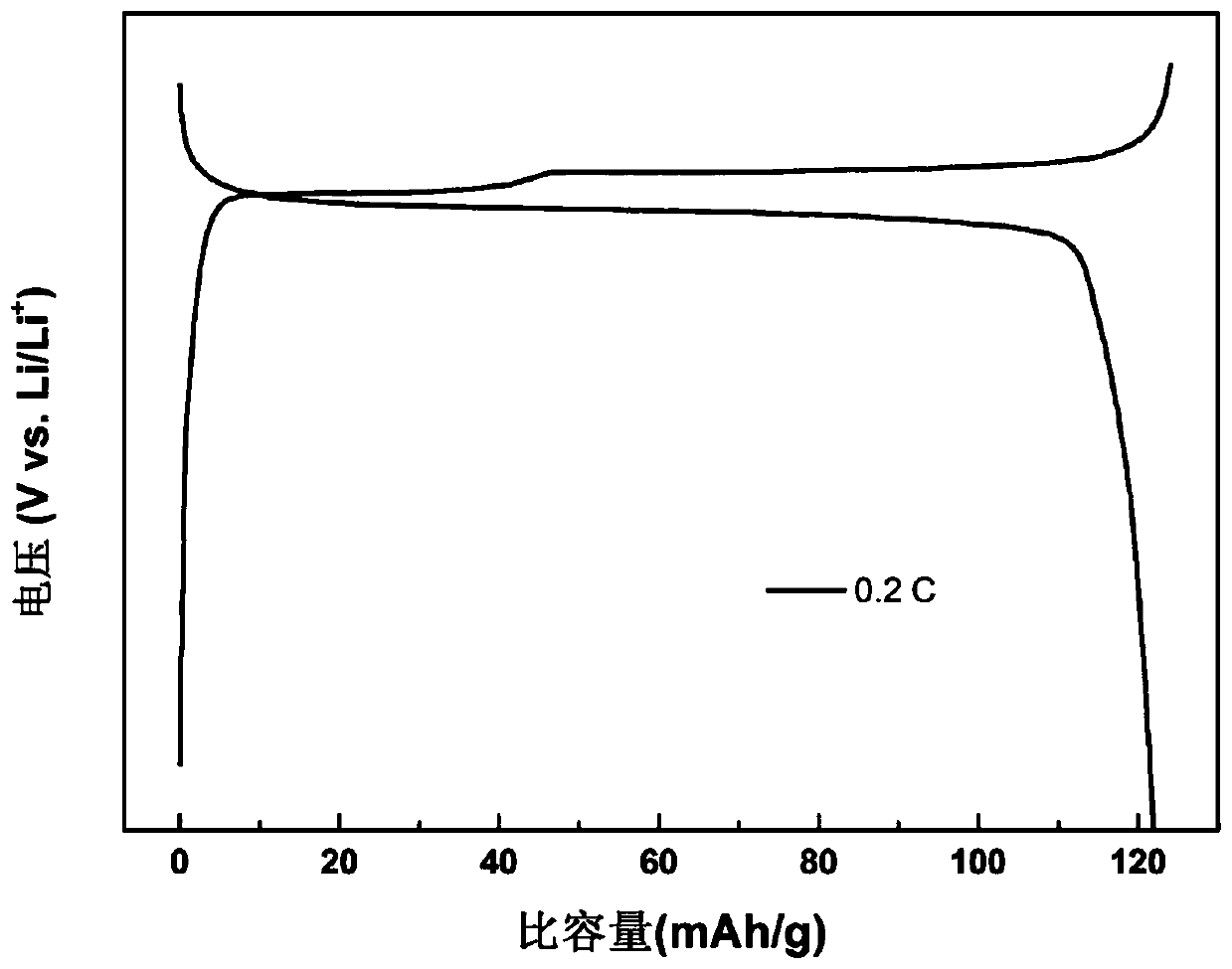

[0046] This embodiment discloses a sodium-doped lithium vanadium phosphate material whose general formula is Li 0.85 / Na 0.15 VPO 4 F.

[0047] The preparation method of the sodium-doped lithium vanadium phosphate material comprises the following steps:

[0048] Mix ammonium metavanadate and ammonium dihydrogen phosphate at V:P=1, and then add 30% of the total weight of glucose to obtain a vanadium phosphate precursor. After drying at 60°C for 4 hours, put it in a tube furnace under the protection of nitrogen atmosphere Raise it to 900°C at a rate of 5°C / min, keep it at this temperature for 10 hours, and then lower it to room temperature to obtain vanadium phosphate, and then mix vanadium phosphate, lithium fluoride and sodium fluoride in the molar ratio V:Li:Na= Mix 1:0.85:0.15, raise the temperature to 600°C at a rate of 4°C / min under a nitrogen protective atmosphere, keep it warm for 6 hours, and cool to room temperature with the tube furnace to obtain sodium-doped lithi...

Embodiment 3

[0051] This embodiment discloses a sodium-doped lithium vanadium phosphate material whose general formula is Li 0.9 / Na 0.1 VPO 4 F.

[0052] The preparation method of the sodium-doped lithium vanadium phosphate material comprises the following steps:

[0053] Mix ammonium metavanadate and concentrated phosphoric acid at V:P=1, and then add fructose accounting for 40% of the total weight to obtain a vanadium phosphate precursor. After drying at 80°C for 3 hours, put it in a tube furnace under the protection of nitrogen atmosphere Raise to 800°C at a rate of 5°C / min, keep at this temperature for 10 hours, then drop to room temperature to obtain vanadium phosphate, and then mix vanadium phosphate, lithium fluoride and sodium fluoride in the molar ratio Li:Na::V : P=0.9:0.1:1:1 for mixing, under a nitrogen protective atmosphere, the heating rate is raised to 600°C at a rate of 4°C / min, kept for 6 hours, and cooled to room temperature with the tube furnace to obtain sodium-dope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge and discharge specific capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com