Coaxial resonant cavity mixed coupling method

A coaxial resonant cavity, hybrid coupling technology, applied in electrical components, circuits, waveguide devices, etc., can solve the problems of complex capacitive coupling structure, difficult to fine-tune the coupling strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

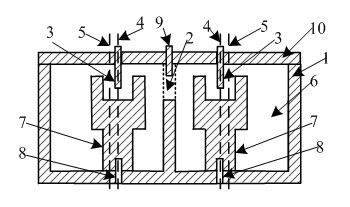

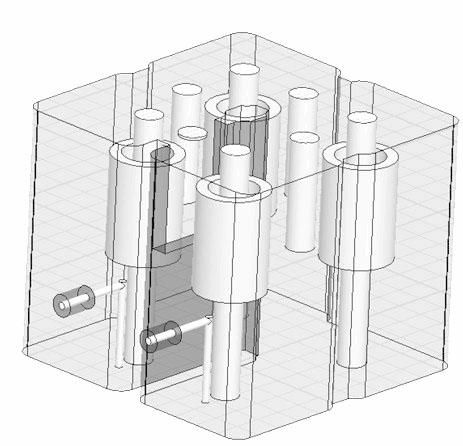

[0024] Such as figure 1 As shown, a coaxial resonant cavity hybrid coupling method includes a conductor shell 1, and two resonant cavities 6 are opened in the conductor shell 1, and the top of the conductor shell 1 is sealed by a conductor cover plate 10; each resonant cavity 6 includes a conductor Resonant rod 7, the upper end of the conductor resonant rod 7 has a cavity, the lower end is a rod body structure, the conductor resonant rod is cylindrical, the upper radius of the conductor resonant rod 7 is large, the lower radius is small, the cavity is at the upper end of the large radius, and the conductor resonant rod 7 The bottom end is fixed in the resonant cavity 6 by fastening screws 8, forming a vertical structure with the bottom surface of the resonant cavity 6, the conductor resonant rod 7 is a conductor, and contacts with the conductor shell 1 to form a short circuit; there is a tuning screw 3 on the conductor cover plate 10; the tuning screw 3. Adjust from top to bot...

Embodiment 2

[0027] The same coaxial resonant cavity hybrid coupling method also includes a conductor shell 1, and two resonant cavities 6 are opened in the conductor shell 1, and the top of the conductor shell 1 is sealed by a conductor cover plate 10; Including a conductor resonance rod 7, the upper end of the conductor resonance rod 7 has a cavity, the lower end is a rod body structure, the horizontal section of the conductor resonance rod is quadrilateral, the upper and lower radii of the conductor resonance rod 7 are the same, and the bottom end of the conductor resonance rod 7 is fixed by fastening screws 8 In the resonant cavity 6, it forms a vertical structure with the bottom surface of the resonant cavity 6, and the conductor resonant rod 7 is a conductor, which is in contact with the conductive shell 1 to form a short circuit; there is a tuning screw 3 on the conductor cover plate 10; the tuning screw 3 adjusts the extension guide from top to bottom In the cavity at the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com