Exothermic enamel glaze, and exothermic container coated with same

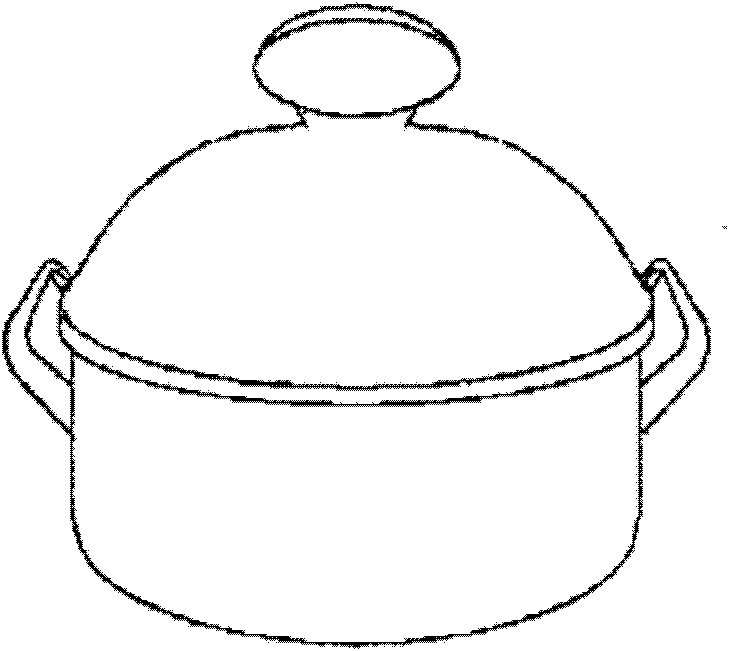

一种发热容器、珐琅釉的技术,应用在发热珐琅釉料及涂布它的发热容器领域,能够解决破损可能性高、复杂形状困难加工、重量重等问题,达到高发热特性、耐热特性优秀、可调节发热温度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

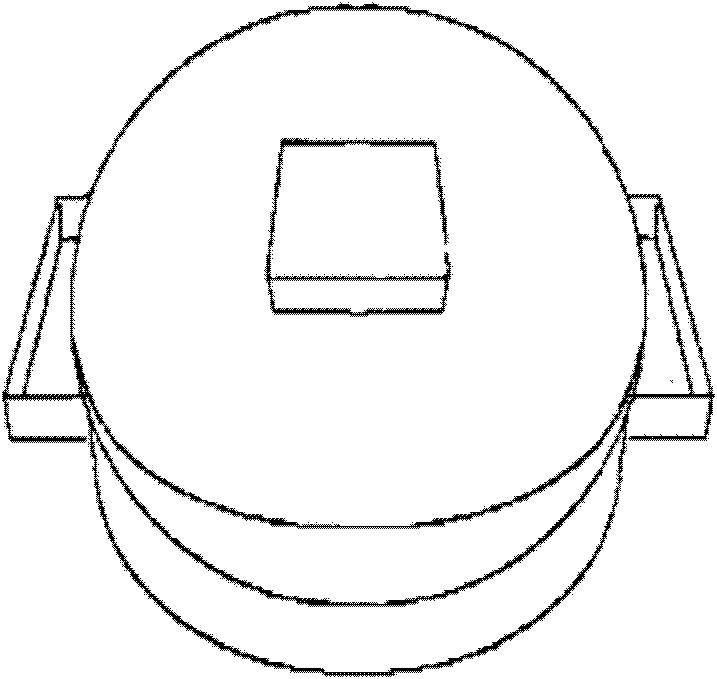

Image

Examples

Embodiment 1

[0068] Vitreous glaze [(Frit), SiO for enamel glaze commonly used 2 、Al 2 o 3 、Na 2 O, K 2 O, CaO, NiO, CoO, CuO, MnO, BaO, F, B 2 o 3 etc.], add clay (clay) and sodium nitrite (NaNO 2) in the composition of commonly used glazes formed by changing the types and contents of soft magnetic materials, namely ferrite and soft magnetic metal alloy powders (FeSiAl, FeSi), to determine the composition ratio of 12 kinds of glazes. 40 wt % of water was added to the composition, and then pulverized to an average particle size of 100 μm by an alumina ball mill to manufacture a test piece of the glaze for heat-generating enamel.

[0069] A hot-rolled steel plate for common enamel is made into a quadrilateral test piece with a thickness of 0.8mm and 100*150mm. After the steel plate is degreased with sodium hydroxide (NaOH), the heating enamel glaze is coated with a thickness of more than 200 μm, and then After drying at 100°C for 2 hours, the dried test piece was vitrified and fired ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com