Weeding composition and application thereof

A herbicidal composition and compound technology, applied in the application, herbicide, algicide, biocide and other directions, can solve the problems of large dosage, low control effect, narrow herbicidal spectrum and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

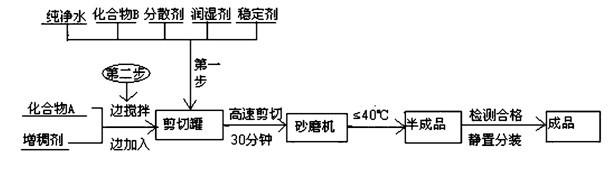

Image

Examples

Embodiment 1

[0047] 51.5% trifluoromethylsulfuron-acetochlor (3:100), dispersible oil suspension

[0048] Pump 395.5 grams of methyl oleate into the shear tank, pump 45 grams of MF, 22 grams of osmotic T, 5 grams of defoamer, and 5 grams of formaldehyde into the shear tank, and then add 15 grams of trifluoromethanesulfonate while stirring. Long, 500 grams of acetochlor, 2.5 grams of xanthan gum, and 10 grams of bentonite were put into the shear tank in order, and the materials were mixed evenly by shearing for 30 minutes. The material is ball milled, the temperature of the ball mill is controlled below 40 degrees, and the fineness of the discharge material passes through a 325 mesh sieve to obtain a 51.5% acetochlor dispersible oil suspension herbicidal composition.

Embodiment 2

[0050] 21% trifluoromethylsulfuron-alachlor (1:20), dispersible oil suspension

[0051] Pump 704.5 grams of methyl oleate into the shear tank, pump 45 grams of MF, 18 grams of NNO, 5 grams of defoamer, and 5 grams of formaldehyde into the shear tank, and then add 10 grams of trifluoromethylsulfuron while stirring , 200 grams of alachlor, 2.5 grams of xanthan gum, and 10 grams of magnesium aluminum silicate are put into the shear tank in order, and the materials are mixed evenly by shearing for 30 minutes. The material is ball milled, the temperature of the ball mill is controlled below 40 degrees, and the fineness of the discharge material passes through a 325-mesh sieve to obtain a 21% triflumesulfuron-alachlor dispersible oil suspension herbicidal composition.

Embodiment 3

[0053] 70.5% trifluoromethylsulfuron-metolachlor (1:140), microcapsule powder

[0054] With 25 grams of DMF, 5 grams of trifluoromethylsulfuron-methyl is completely dissolved and pumped into the shear tank, 700 grams of metolachlor, 30 grams of phenylphenol polyoxyethylene polyoxypropylene ether and its sulfate (or phosphate ester) , 30 grams of calcium dodecylbenzenesulfonate, 180 grams of urea-formaldehyde resin prepolymer, 3 grams of defoamer, after shearing, slowly add 180 grams of initiator while stirring, slowly stir at 60 °C for half an hour, and then pass Freeze dry under vacuum. A 70.5% triflumesulfuron-metolachlor microcapsule powder herbicidal composition can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com