Preparation method of CeO2-MnO2 composite catalyst with efficient photothermal concerted catalytic purification function for VOCs (Volatile Organic Chemicals)

A composite catalyst, photothermal synergy technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problems of limitation and high price, and achieve the reaction conditions Mild, easy to industrialize, cheap and easy to obtain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] CeO with efficient photothermal synergistic catalytic purification of VOCs 2 -MnO 2 The preparation method of composite catalyst (Ce / Mn molar ratio is 1:3) is as follows:

[0031] (1) Weigh 0.01molCe(NO 3 ) 3 ·6H 2 O and 0.03mol KMnO 4 , added to a beaker with 60ml of water, and magnetically stirred to obtain Ce(NO 3 ) 3 ·6H 2 O and KMnO 4 mixture;

[0032] (2) Transfer the mixed solution to a 100 ml stainless steel reaction kettle with a polytetrafluoroethylene liner, seal it, and react at 120°C for 24 hours;

[0033] (3) After the reaction is completed, wait for the reaction kettle to cool down to room temperature, take out the precipitate in the polytetrafluoroethylene liner, filter, wash, and dry to obtain CeO 2 -MnO 2 Composite catalyst.

example 3

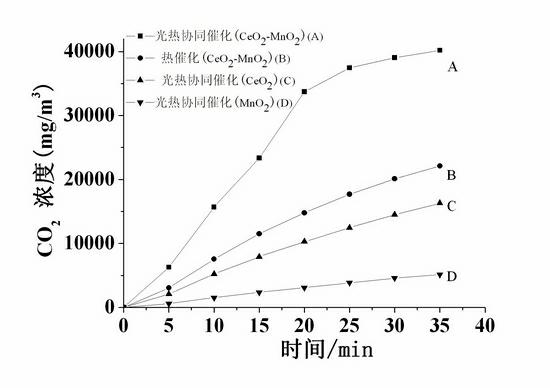

[0054] Comparative Example 3(a)

[0055] The CeO that embodiment 1 obtains 2 -MnO 2 The composite catalyst thermally degrades 100 μl of benzene, and the catalytic reaction temperature is 200°C.

example 3

[0057] Comparative Example 3(b)

[0058] Weigh 15gCe(NO 3 ) 3 ·6H 2 O and 6 g of urea were added to a 250 ml round bottom flask filled with 40 ml of distilled water and sonicated. Put the flask into a microwave oven (50Hz, 800W) and heat the reaction for 30min. After the reaction, the precipitate was taken out, filtered with distilled water, washed, dried, and then calcined at 400°C for 2h to obtain nano-CeO 2 powder.

[0059] The resulting CeO 2 The photothermal synergistic thermal catalytic degradation of 100 μl benzene was carried out by the catalyst, and the catalytic reaction temperature was 200 °C. CeO 2 Photothermal Synergistic Catalytic Degradation of 100 μl Benzene Produced CO 2 The relationship between concentration change and time see image 3 In curve C, after 35 min of photothermal synergistic catalysis, CO 2 The increment is 16305mg / m 3 , CO 2 The formation rate is 10.59μmol / min·m 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com