High-efficiency clean process for cleaning and graded milling of wheat

A wheat and process technology, applied in solid separation, grain processing, sieving and other directions, to achieve the effect of lower power consumption per ton of flour, improved cleaning effect, and high yield of high-quality flour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

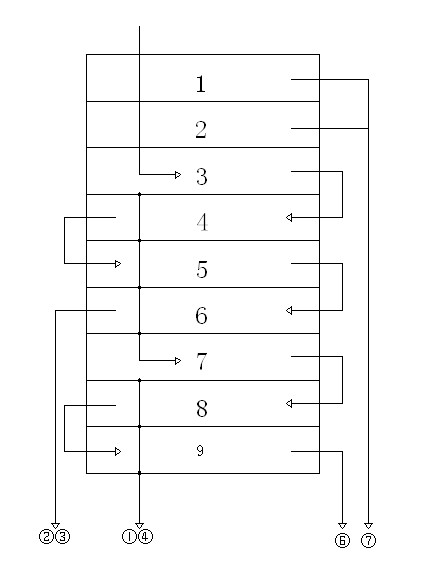

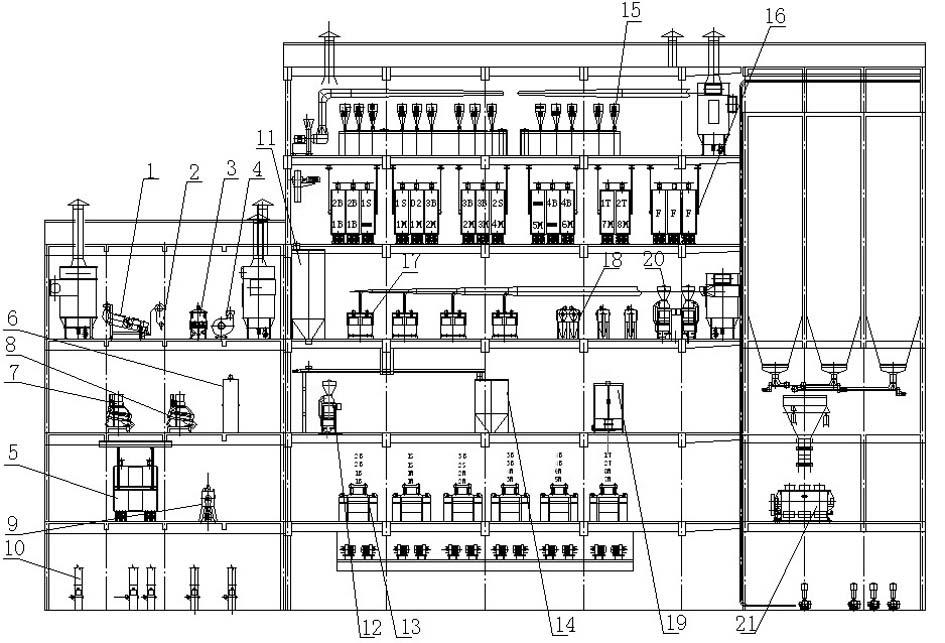

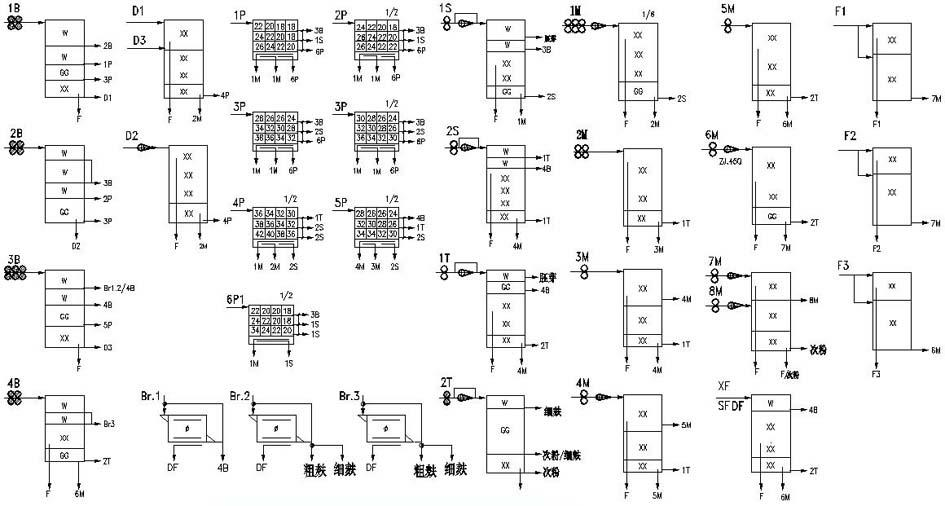

[0032] Such as figure 1 , figure 2 and image 3 As shown, in the figure and in the content of the present invention, B represents skin mill, M represents heart mill, S represents slag mill, T represents tail mill, Br represents bran beating machine, Sr represents bran brushing machine, P represents powder clearing, DF represents Bran beating powder, XF stands for suction powder, SF stands for brushing bran powder, F stands for flour, Bran stands for bran, and D stands for heavy sieving.

[0033] The wheat after primary cleaning to remove the large impurities enters the high-efficiency self-balancing vibrating screen 1 and the circulating wind separator 2 to remove the fine impurities and wheat husk light impurities from the wool wheat warehouse, and then enters the heavy wheat stone removal machine 7 to remove stones, and then enters Wheat is cleaned with a square planar sieve 5 for sieving and grading. After sieving, the wheat material is classified into heavy wheat with f...

Embodiment 2

[0114] This embodiment includes a high-efficiency cleaning wheat grading and cleaning system, a skin mill system, a core mill system, a slag mill system, a powder cleaning system and a tail mill system; The selected wheat classification cleaning process, four skin mills, seven heart mills, two slag mills, two tail mills, three bran beatings, and one bran brushing process; its technological process and related devices are basically the same as in Example 1 The same, only the heart grinding is changed to seven ways.

Embodiment 3

[0116] This embodiment includes a high-efficiency cleaning wheat grading and cleaning system, a skin mill system, a core mill system, a slag mill system, a powder cleaning system and a tail mill system; two stone removal, two sieves, one suction separation, and one selected wheat cleaning are used. Technology, four skin mills, eight heart mills, two slag mills, two tail mills, and three processing techniques for beating bran; its technological process and related devices are basically the same as in Example 1, except that one step is reduced in the cleaning system The process of brushing wheat and reducing the process of brushing bran in the milling system.

[0117] Compared with the traditional technology, the invention shortens the wheat cleaning process, increases the sieving area and greatly reduces the use of vibrating sieves, reduces the plant investment in the wheat cleaning section; classifies and mills the wheat, reduces the ash content, and improves the yield of high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com