Preparation method for reduced graphene oxide

A graphene and graphene film technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as high energy consumption and high pollution, achieve good electrical conductivity, avoid transfer process, and facilitate continuous production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The present invention provides a method for preparing reduced graphene oxide, which is characterized in that the method comprises contacting graphene oxide and metal or reduced metal oxide with an acid.

[0018] In the present invention, the way of contacting the graphene oxide and the metal or reducing metal oxide with the acid can be various ways known in the art. For example, after graphene oxide is prepared into graphene oxide hydrosol, the graphene oxide hydrosol is coated on the substrate, and dried at 60-100°C to obtain a graphene oxide film, and a layer of metal or reduction is applied on the surface of the graphene oxide film. active metal oxide to obtain a graphene oxide film covered with metal or reducing metal oxide, contact the obtained graphene oxide film covered with metal or reducing metal oxide with acid, remove the metal layer, and dry.

[0019] In the present invention, the above-mentioned drying method may be various methods known in the art. In the...

Embodiment 1

[0031] 1g of natural flaky graphite was added into 20g of concentrated sulfuric acid with a concentration of 95% by weight, stirred overnight in an ice bath at 0°C, then 0.15g of potassium permanganate was added to the resulting mixture, stirred for 30min before adding 3g of potassium permanganate and control the temperature below 20°C; then raise the temperature to 35°C and maintain this temperature for 30min, then add 45mL of water to the mixture, raise the temperature to 90-95°C, and maintain this temperature temperature for 15 minutes; then add 30 mL of hydrogen peroxide with a concentration of 30% by weight, stir for 30 minutes and then add 26 mL of water, filter while hot, wash 3 times with 50 mL of hydrochloric acid with a concentration of 3% by weight, and put the resulting filter cake into 400 mL Ultrasonic treatment in water for 1h, the obtained dispersion was centrifuged at 3000r / min to remove the graphene oxide particles that were not completely peeled off to obtain...

Embodiment 2

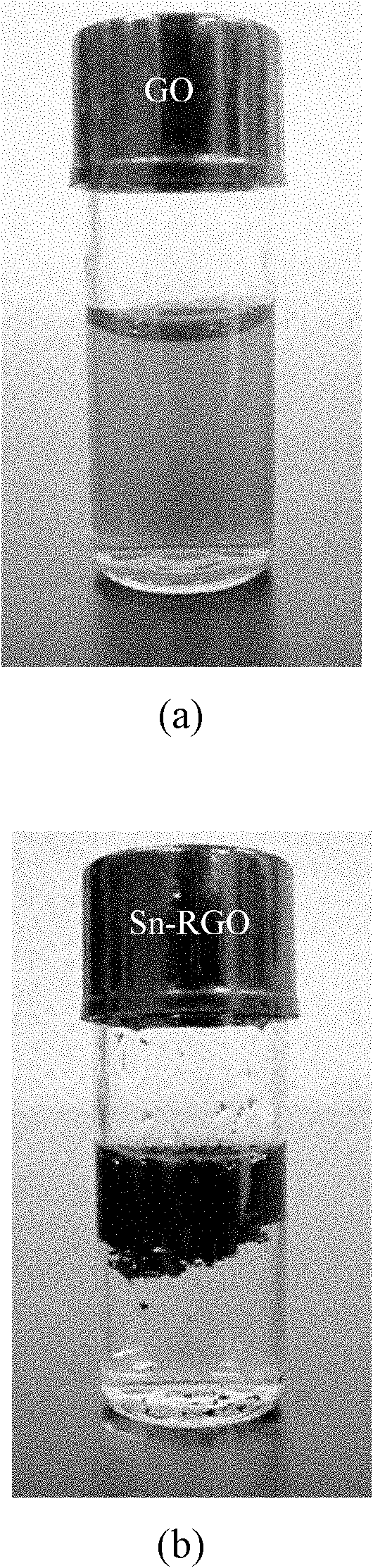

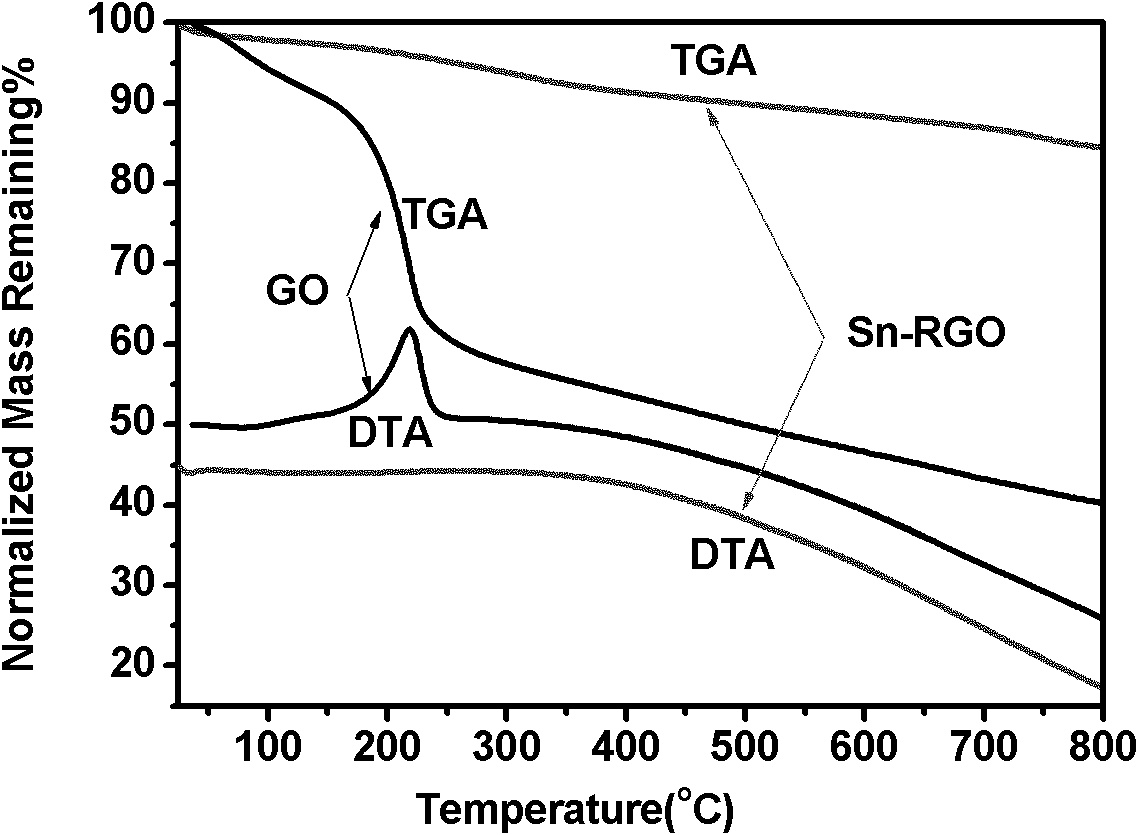

[0033]Add metal tin powder (Tianjin Kemiou Chemical Reagent Co., Ltd.) 1g (8.4mmol) in 100mL of 1mg / mL graphene oxide hydrosol prepared in Example 1 and mix, then add concentrated hydrochloric acid (mass fraction is 37 %) 4mL (1.48g relative to the weight of the acid), stir for 4h, until the solution turns black, filter, wash with 1mol / L hydrochloric acid (30mL x 3 times), wash with deionized water (50mL x 5 times) , filtered to obtain reduced graphene oxide. This reduced graphene oxide is added in 5mL water, the photograph of gained mixture is as follows figure 1 Shown in (b), the thermogravimetric analysis see figure 2 The RGO curve in .

[0034] according to figure 1 It can be seen that the reduced product is insoluble in water, indicating that reduced graphene oxide is generated. according to figure 2 It can be seen from the thermogravimetric analysis chart that graphene oxide has obvious weight loss, but the reduced Sn-RGO has no obvious weight loss. It shows that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com