Dry-mixed surface mortar for external insulation of building exterior wall and preparation method thereof

A technology for plastering mortar and building exterior walls, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as waste of resources, poor waterproof performance, inaccurate measurement, etc., and achieve improved waterproof performance , Excellent construction performance, and the effect of improving slip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A dry-mixed plastering mortar for external thermal insulation of building exterior walls, which is made of the following raw materials in proportions by weight: 35 parts of cement; 10 parts of fly ash; 55 parts of sand; 0.15 parts of cellulose ether; 0.25 parts of wood fiber; 0.20 parts of agent; 2.5 parts of redispersible rubber powder; 0.02 parts of starch ether.

[0035] Its preparation method is to accurately measure each component according to the proportion, then add it to the mixing equipment in turn, and stir evenly to obtain the finished product. When using it, add 22 parts of water and stir for 3-5 minutes. After stirring evenly, the color is consistent, and then it can be used for building construction.

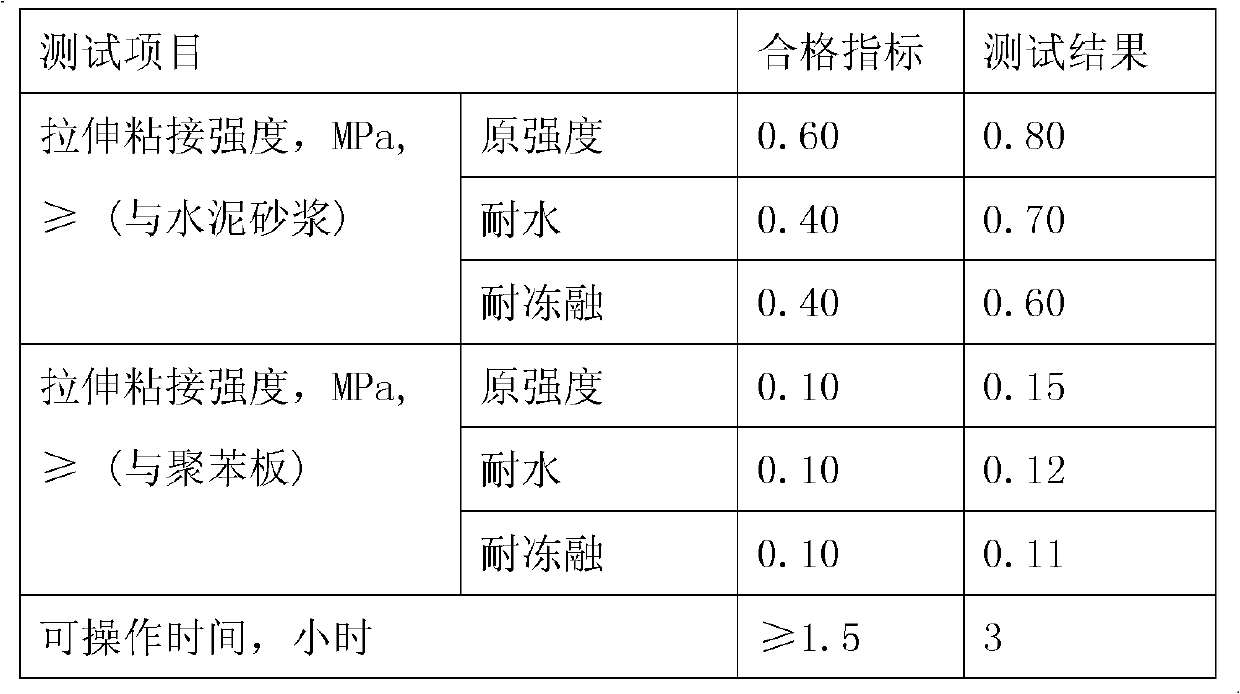

[0036] The results of the tensile bond strength test are shown in Table 1.

[0037] Table 1

[0038]

Embodiment 2

[0040] A dry-mixed plastering mortar for external thermal insulation of building exterior walls, which is made of the following raw materials in proportions by weight: 25 parts of cement; 25 parts of fly ash; 50 parts of sand; 0.2 part of cellulose ether; 0.25 part of wood fiber; 0.20 parts of agent; 2.5 parts of redispersible rubber powder; 0.05 parts of starch ether.

[0041] Its preparation method is to accurately measure each component according to the proportion, then add it to the mixing equipment in turn, and stir it evenly to form a finished product. When using it, add 19 parts of water and stir for 3-5 minutes. After stirring evenly, the color is consistent, and then it can be used in building construction.

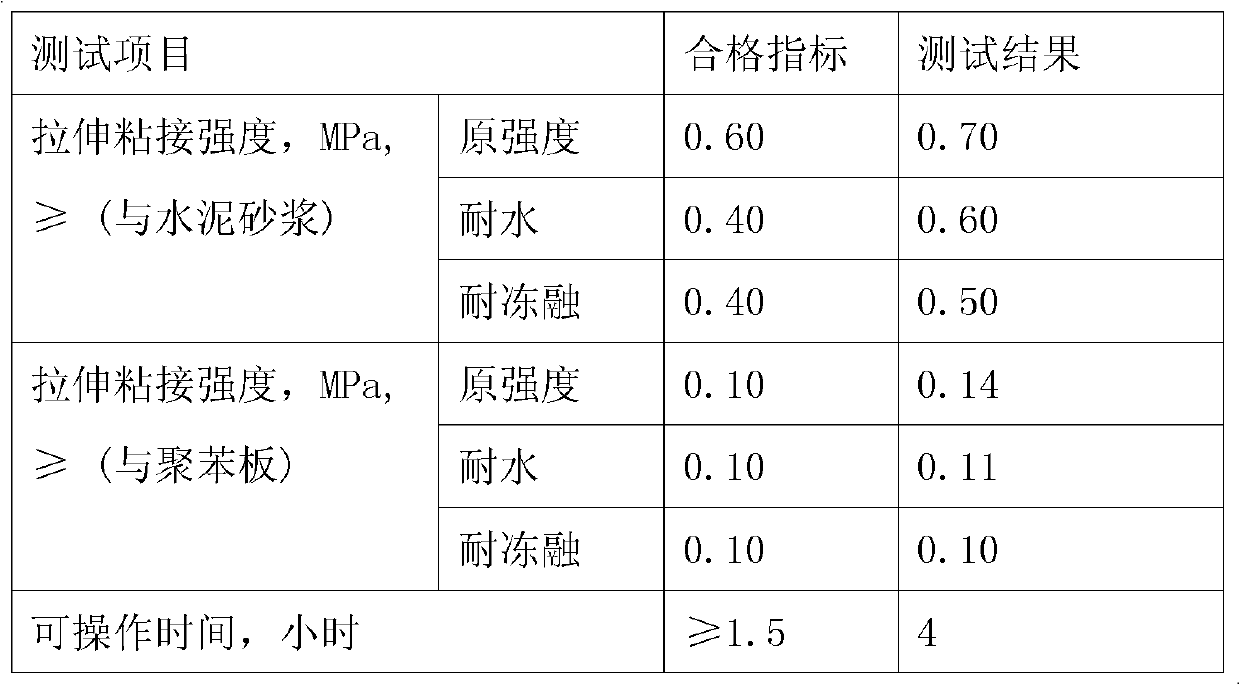

[0042] The results of the tensile bond strength test are shown in Table 2.

[0043] Table 2

[0044]

Embodiment 3

[0046] A dry-mixed plastering mortar for external thermal insulation of building exterior walls, which is made of the following raw materials in proportions by weight: 28 parts of cement; 10 parts of fly ash; 62 parts of sand; 0.2 parts of cellulose ether; 3 parts of redispersible rubber powder ; 0.35 parts of starch ether; 0.3 parts of wood fiber; 0.25 parts of water-repellent agent.

[0047] Its preparation method is to accurately measure each component according to the proportion, then add it to the mixing equipment in turn, and stir it evenly to become the finished product. When using it, add 22 parts of water and stir for 3-5 minutes. Stir evenly and the color is consistent, then it can be used in construction. .

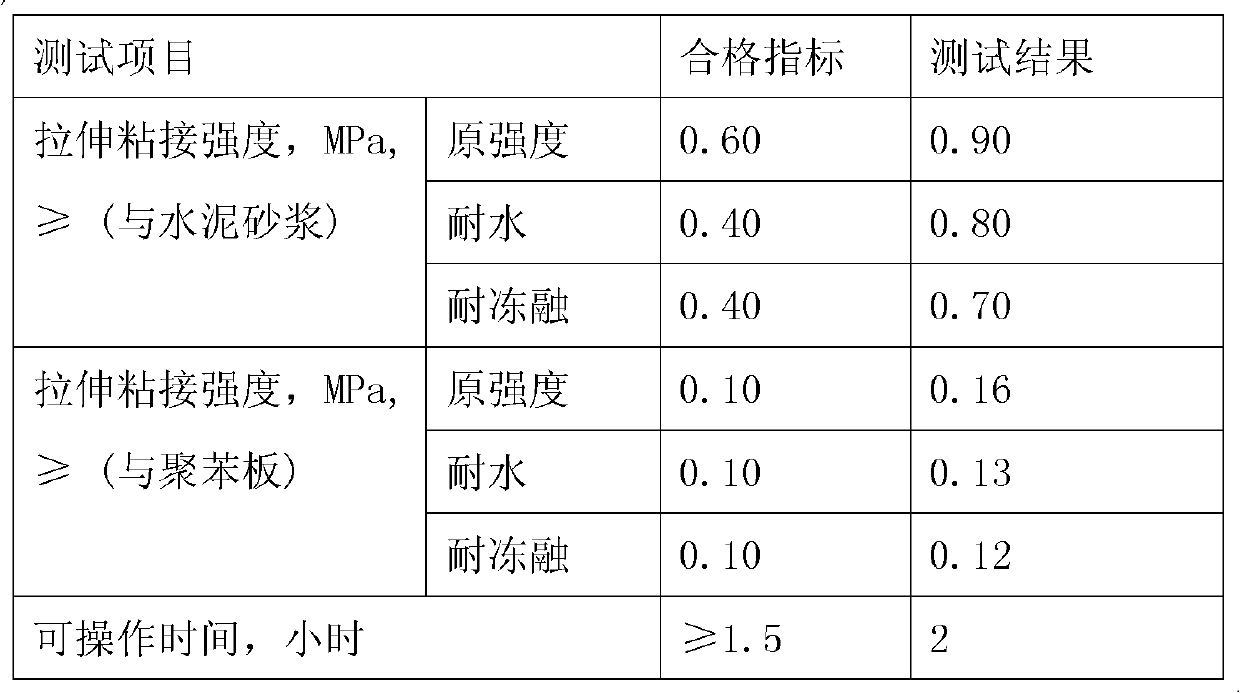

[0048] The results of the tensile bond strength test are shown in Table 3.

[0049] table 3

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com