Preparation method for fatty acid derivate cation asphalt emulsifying agent

A technology of fatty acid derivatives and asphalt emulsifier, which is applied in building structures, building components, building insulation materials, etc., can solve the problems of high price and complicated preparation process, and achieves low concentration, good water solubility and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Prepare mixed fatty acids

[0028] Add 46.2 g of sunflower oil containing 70% linoleic acid, 1.4 g of sodium dodecyl sulfonate, 4.6 g of sulfuric acid solution with a mass fraction of 98%, and 92.4 g of distilled water into the reactor. The sunflower oil and dodecane The mass ratio of sodium sulfonate, 98% sulfuric acid solution and distilled water is 1:0.03:0.1:2, the temperature is increased to 95° C., the reaction is kept at a constant temperature for 12 hours, and the oil and water are separated after the reaction is completed to obtain the mixed fatty acid.

[0029] 2. Preparation of tricarboxylic acid intermediates

[0030] Mix 20.0g of mixed fatty acid, 5.4g of maleic anhydride, anhydrous AlCl 3 0.4g is added to the reactor and mixed evenly, the mass ratio of mixed fatty acid and maleic anhydride is 3.7:1, maleic anhydride and anhydrous AlCl 3 The molar ratio is 1:0.05, the temperature is raised to 140°C, and the reaction is kept at a constant temperature for 4 hour...

Embodiment 2

[0036] 1. Prepare mixed fatty acids

[0037] Add 46.0 g of soybean oil containing 50-60% linoleic acid, 1.2 g of sodium dodecylbenzene sulfonate, 5.0 g of sulfuric acid solution with a mass fraction of 98%, and 46.0 g of distilled water into the reactor. The mass ratio of sodium alkylbenzene sulfonate, 98% sulfuric acid solution and distilled water is 1:0.026:0.11:1, the temperature is raised to 100°C, and the reaction is kept at a constant temperature for 10 hours. After the reaction, oil and water are separated to obtain mixed fatty acid.

[0038] 2. Preparation of tricarboxylic acid intermediates

[0039] Mix 20.0g of mixed fatty acid, 4.5g of maleic anhydride, and anhydrous AlCl 3 0.3g is added to the reactor and mixed evenly, the mass ratio of mixed fatty acid and maleic anhydride is 4.4:1, maleic anhydride and anhydrous AlCl 3 The molar ratio of is 1:0.05, the temperature is raised to 160°C, and the reaction is kept at a constant temperature for 4 hours to obtain the tricarbox...

Embodiment 3

[0045] 1. Prepare mixed fatty acids

[0046] Add 46.0 g of cottonseed oil containing 44.9-55.0% of linoleic acid, 1.2 g of sodium lauryl sulfonate, 5.0 g of sulfuric acid solution with a mass fraction of 98%, and 46 g of distilled water into the reactor. The mass ratio of sodium sulfonate, 98% sulfuric acid solution and distilled water is 1:0.026:0.11:1, the temperature is raised to 100°C, and the reaction is kept at a constant temperature for 9 hours. After the reaction, the oil and water are separated to obtain the mixed fatty acid.

[0047] 2. Preparation of tricarboxylic acid intermediates

[0048] Mix 20.0g of mixed fatty acid, 4.6g of butenedioic acid, anhydrous ZnCl 2 0.25g is added to the reactor and mixed evenly, the mass ratio of mixed fatty acid and butenedioic acid is 4.3:1, butenedioic acid and anhydrous ZnCl 2 The molar ratio of is 1:0.02, the temperature is raised to 140°C, and the reaction is kept at a constant temperature for 4 hours to obtain the tricarboxylic acid...

PUM

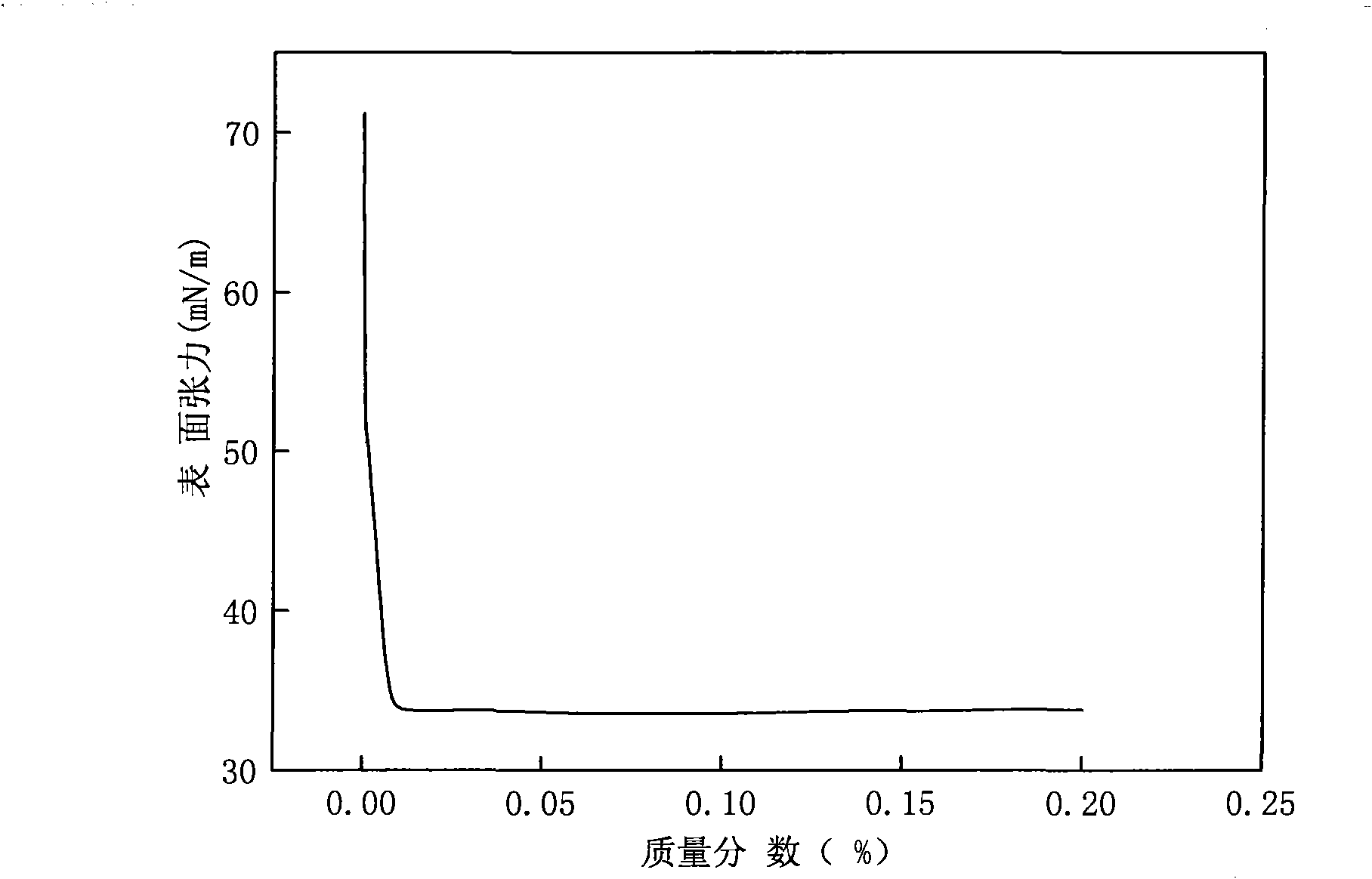

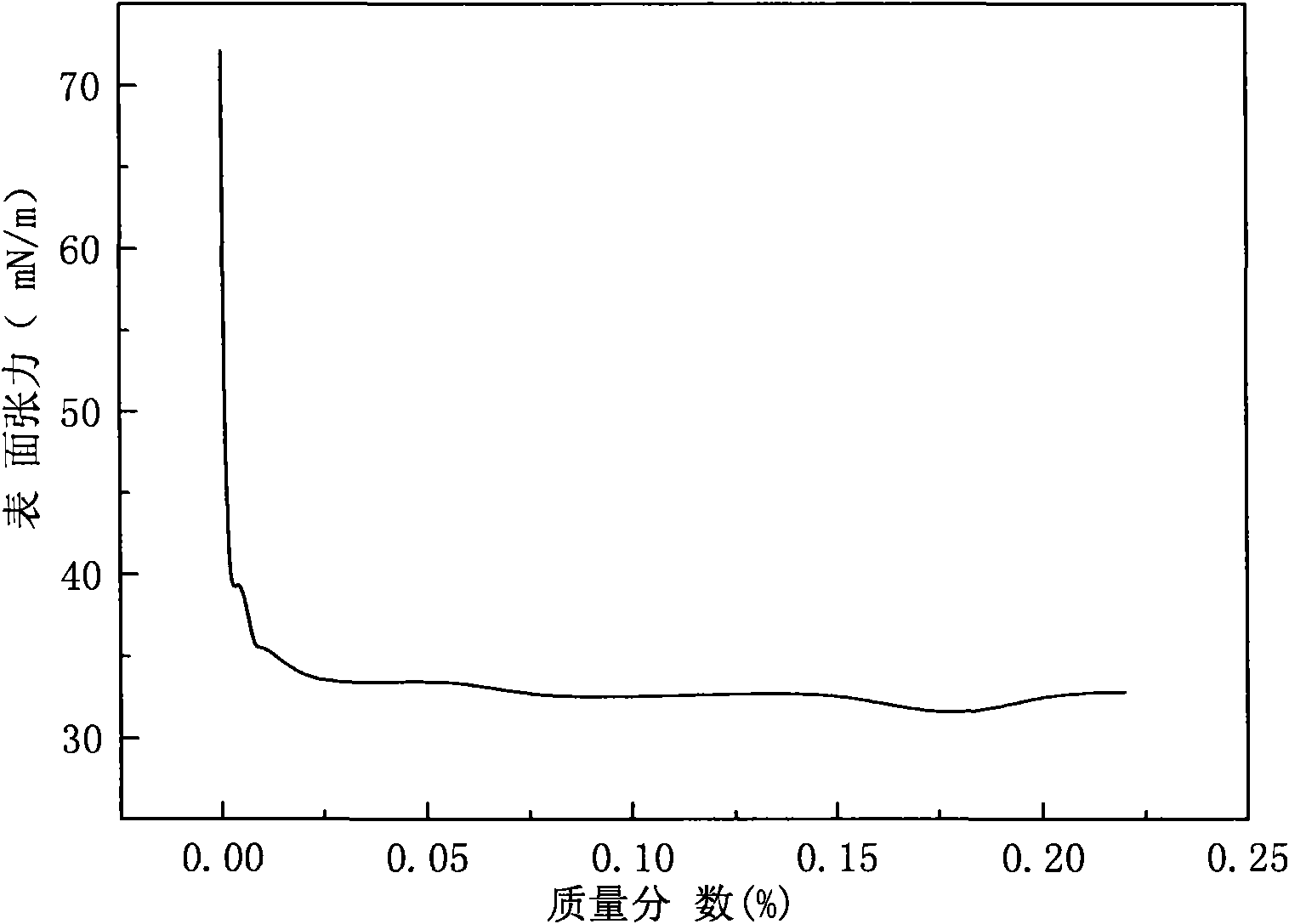

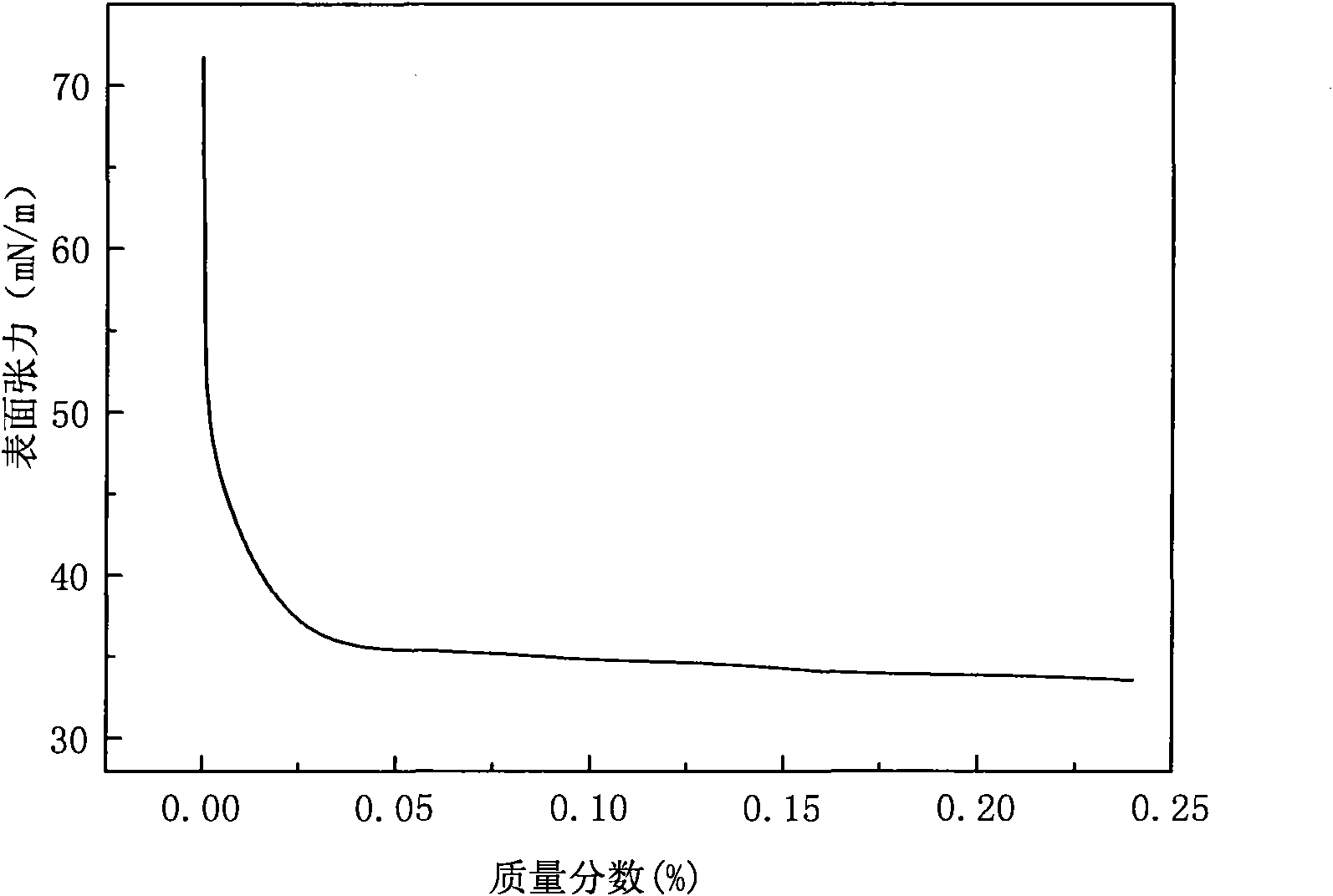

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com