Semiconductor luminescent material with adjustable luminescent colours and preparation method

A technology of light-emitting color and light-emitting material, applied in the direction of light-emitting materials, chemical instruments and methods, etc., can solve the problems of single light-emitting color of light-emitting materials, difficult to achieve effective doping, low doping efficiency, etc., to improve doping efficiency, The effect of rich energy level distribution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

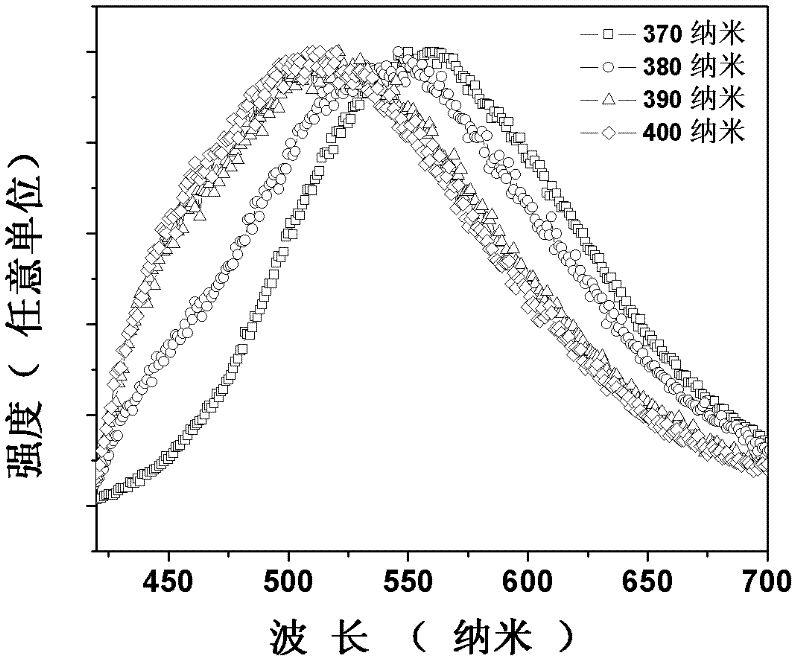

Embodiment 1

[0027] A semiconductor luminescent material with adjustable luminescent color and a preparation method thereof, the steps are as follows:

[0028] 1) Weigh 1.2 g of zinc acetate and 0.02 g of copper acetate, add 55 ml of absolute ethanol, and ultrasonically dissolve for 30 minutes to obtain the precursor solution of zinc source and doping source;

[0029] 2) Weigh 1 g of sodium hydroxide, add 25 ml of absolute ethanol, and ultrasonically dissolve for 30 minutes to obtain the precursor solution of the hydroxyl source, and place the prepared precursor solutions of the zinc source and the doping source in a water bath at 70 °C Heating in a water bath, adding the prepared hydroxyl source precursor solution to the zinc source and doping source precursor solution, and magnetically stirring for 2 h to prepare doped ZnO;

[0030] 3) Disperse the above doped ZnO in 80 ml of absolute ethanol and ultrasonically disperse for 1 hour;

[0031] 4) Weigh 1.2 g of zinc acetate, add 55 ml of a...

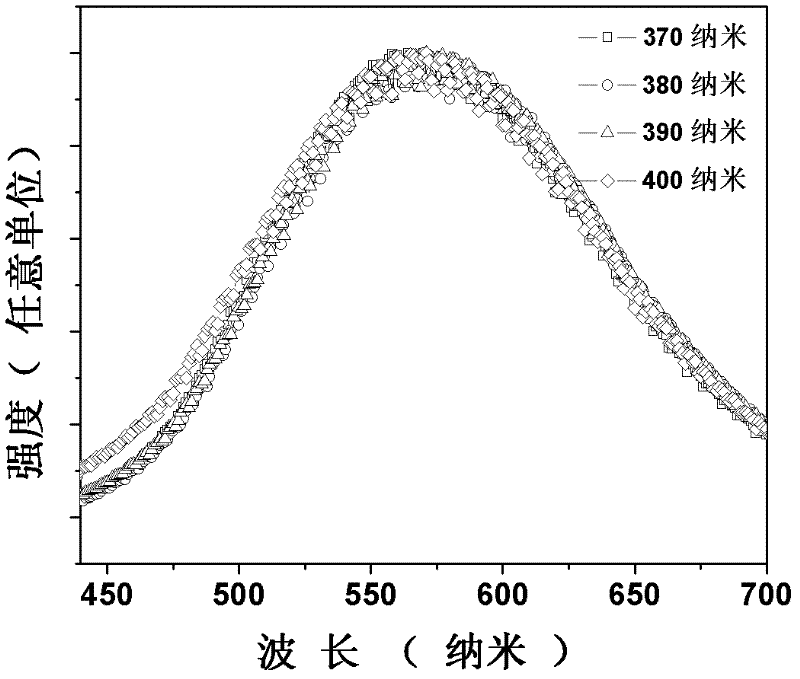

Embodiment 2

[0039] A semiconductor luminescent material with adjustable luminescent color and a preparation method thereof, the steps are as follows:

[0040] 1) Weigh 2.4 g of zinc acetate and 0.04 g of copper acetate, add 110 ml of absolute ethanol, and ultrasonically dissolve for 30 minutes to obtain the precursor solution of zinc source and doping source;

[0041] 2) Weigh 2 g of sodium hydroxide, add 50 ml of absolute ethanol, and ultrasonically dissolve for 30 minutes to obtain the precursor solution of the hydroxyl source, and place the prepared precursor solutions of the zinc source and the doping source in a water bath at 70 °C for heating , and the prepared precursor solution of hydroxyl source was added to the precursor solution of zinc source and doping source, and magnetically stirred for 2 h to prepare doped ZnO;

[0042] 3) Disperse the doped ZnO prepared above in 80 ml of absolute ethanol, and ultrasonically disperse for 1 hour;

[0043] 4) Weigh 1.2 g of zinc acetate, ad...

Embodiment 3

[0048] A semiconductor luminescent material with adjustable luminescent color and a preparation method thereof, the steps and process conditions are the same as those in Example 1, except that the acetate in steps 1 and 4 is changed to nitrate of the same quality. The luminescent properties of the semiconductor luminescent material prepared in this example are the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com