Method for preparing fuel oil by performing microwave cracking on garbage

A fuel oil and garbage technology, applied in the field of garbage treatment and resource utilization, can solve the problems of serious environmental pollution, non-standard discharge, poor equipment operation effect, etc., and achieve the effects of high resource utilization rate, reduced hazards, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

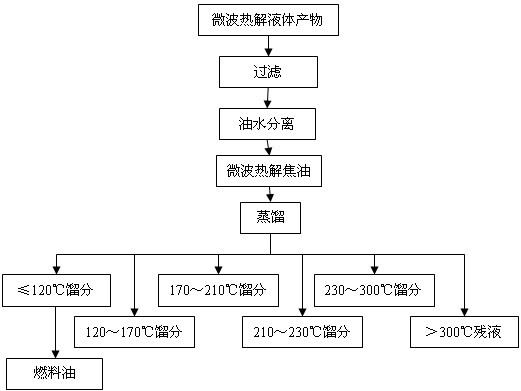

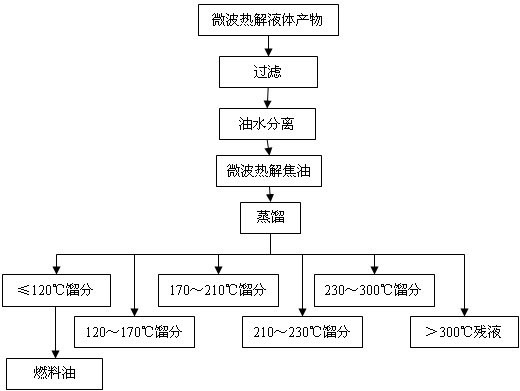

[0020] The present invention prepares fuel oil with garbage microwave cracking gas, and the specific method is as follows, which can be referred to at the same time figure 1 :

[0021] 1) Garbage pretreatment - not all garbage can be cracked, so the present invention pretreats the garbage, sorts the garbage and leaves only organic garbage, and dehydrates and pulverizes to obtain moisture content ≤ 13%, particle size ≤ 100mm structured waste suitable for microwave pyrolysis.

[0022] 2) Microwave cracking of garbage--put the structured garbage obtained in step 1) into the microwave cracking device, and use industrial microwaves with a frequency of 915MHz or 2450MHz to carry out microwave cracking at 350-650°C, and control the internal pressure of the microwave cracking device. Greater than 1.6Mpa. Microwave pyrolysis produces high-temperature cracked gas, and the temperature of the cracked gas is 120°C to 500°C. Pyrolysis gas contains water, tar and ash impurities, the main ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com