Method for extracting sesame oil

An extraction method, sesame oil technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of waste of sesame protein resources, low yield of sesame oil, deep color of sesame oil, etc., to avoid serious denaturation, avoid dark color, equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

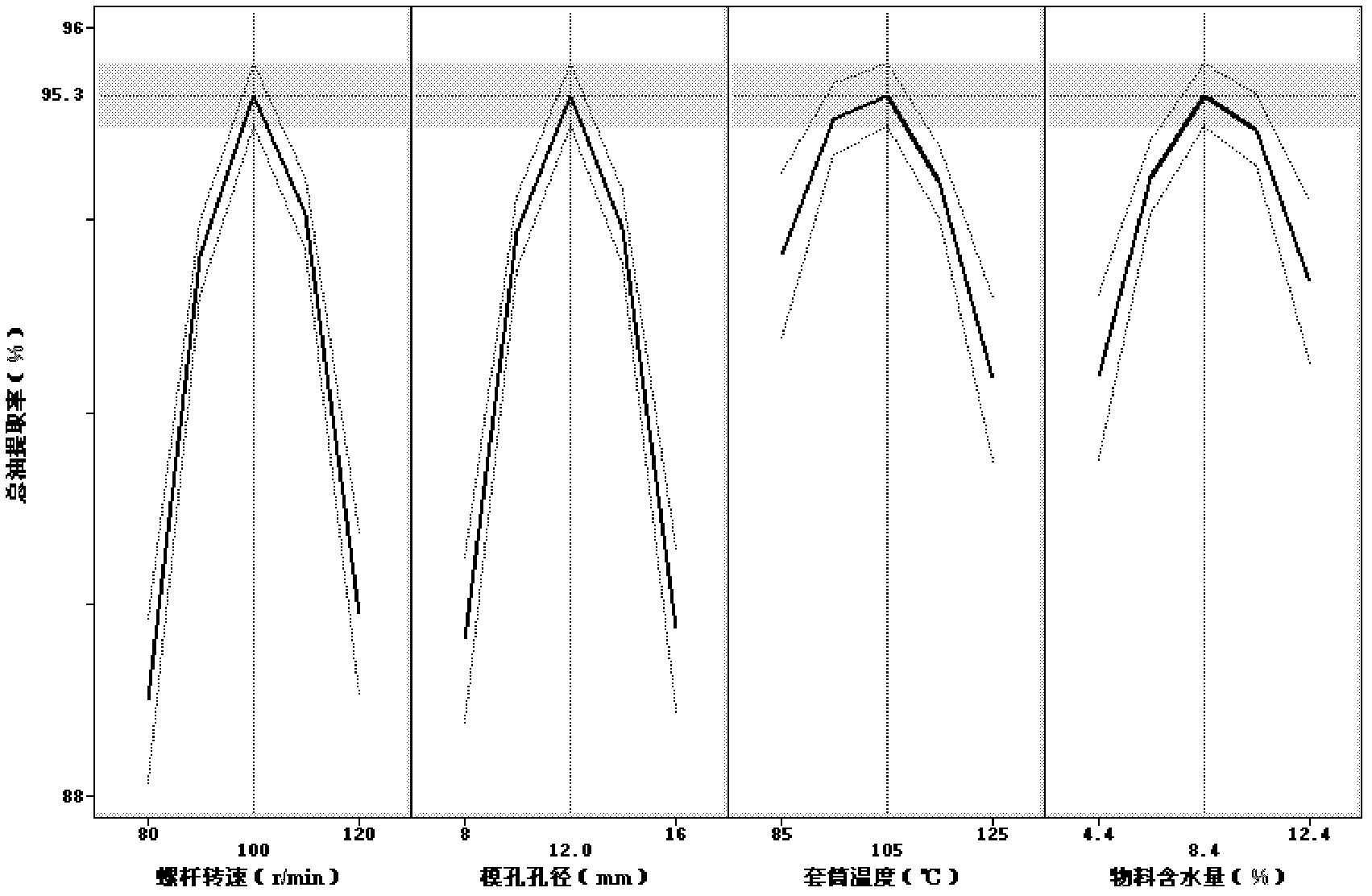

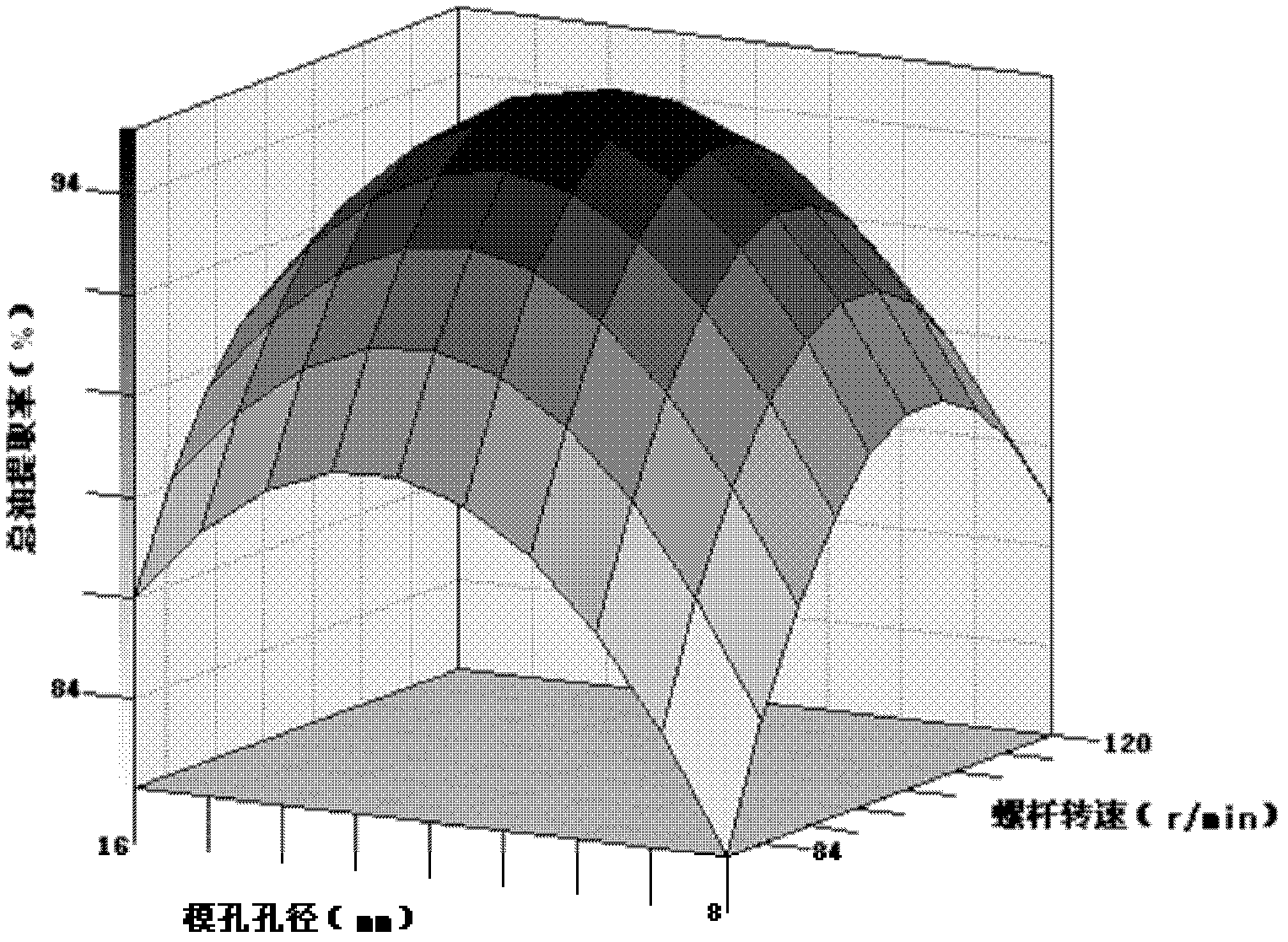

[0044] Example 1 Screening experiment of optimal parameters for sesame extrusion and puffing

[0045] 1 Materials and methods

[0046] 1.1 Materials and reagents

[0047] Sesame Yuzhi No.11

[0048] protex-7L neutral endoprotease Danish novo company

[0049] 1.2 Main instruments and equipment

[0050]

[0051]

[0052]1.3 Experimental method

[0053] 1.3.1 Composition determination of sesame

[0054] Refer to GB / T 5528-2008 for the determination of moisture and volatile matter content; refer to GB / T 5505-2008 for the determination of ash content; refer to GB / T 14489.2-2008 for the determination of crude protein content; refer to GB / T 5512-2008 for the determination of crude fat content; Determination of sugar content, Fehling's reagent method; Determination of crude fiber: according to GB / T22224-2008.

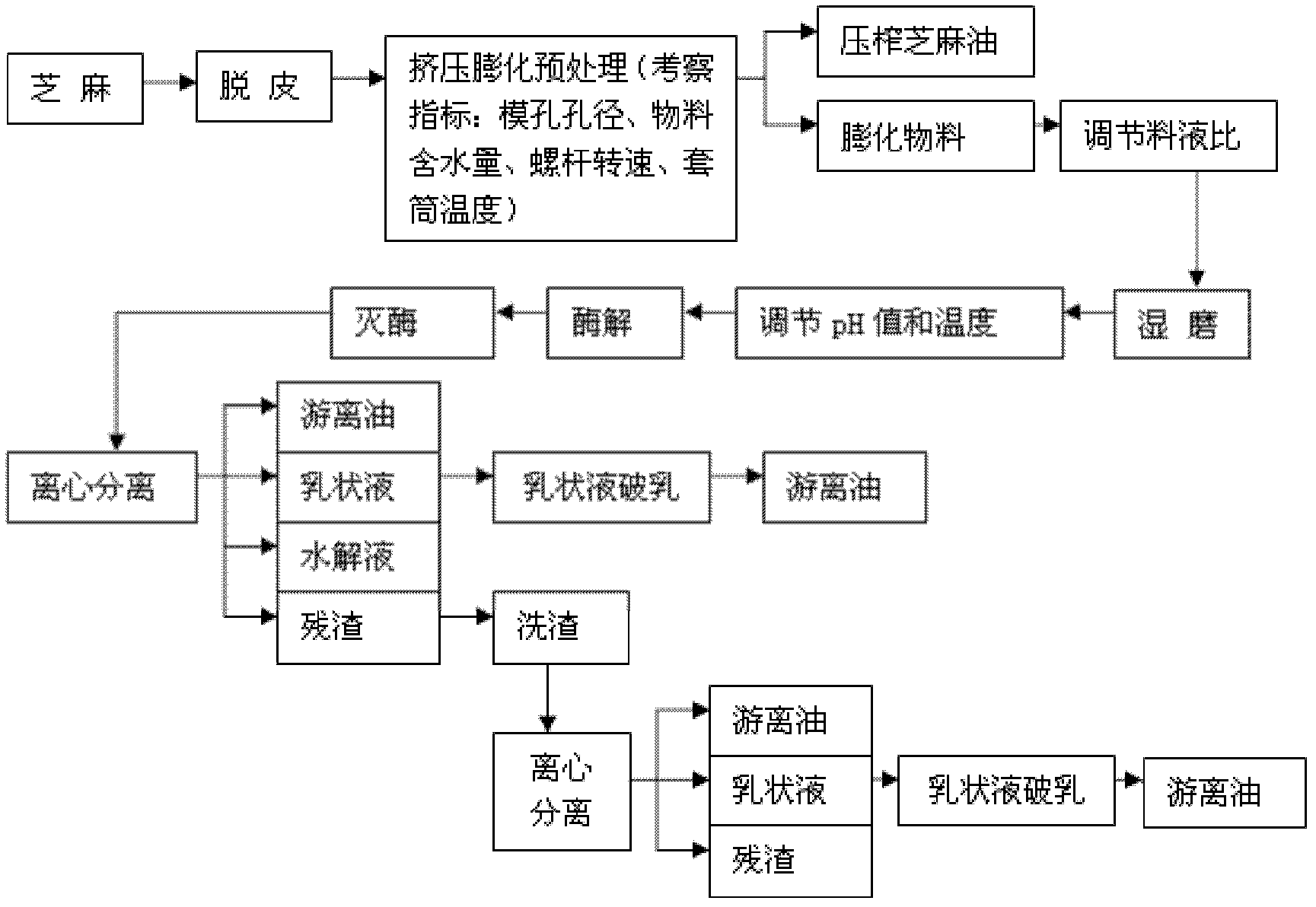

[0055] 1.3.2 Process flow

[0056] Sesame→peeling→extrusion and puffing→adjusting the ratio of material to liquid (1:6)→wet milling→adjusting pH value and temperat...

Embodiment 2

[0088] Example 2 Optimum parameter optimization experiment of enzymatic hydrolysis process of extrusion puffed pretreated white sesame

[0089] Based on the optimal extrusion and expansion pretreatment process determined in Example 1, a single factor enzymolysis test was carried out to determine each enzymolysis process parameter (enzymolysis temperature, enzymolysis pH, enzyme amount, solid-liquid ratio, enzymolysis time) range. Taking the oil extraction rate as the investigation index, a response surface design experiment with 5 factors and 5 levels was carried out.

[0090] 1.1 Materials and reagents

[0091] Sesame Yuzhi No.11

[0092] protex-7L neutral endoprotease Danish novo company

[0093] 1.2 Main instruments and equipment

[0094]

[0095] 1.3 Experimental method

[0096] 1.3.1 Composition determination of sesame

[0097] Refer to GB / T 5528-2008 for the determination of moisture and volatile matter content; refer to GB / T 5505-2008 for the determination of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com