Denim washing pumice-replaced environmental biological coarse pattern enzyme preparation and application thereof

An enzyme preparation, environmental protection technology, applied in the direction of dry cleaning fiber products, plant fiber, biochemical fiber treatment, etc., can solve the problems of high freight rate of pumice, easy to produce holes, low production efficiency, etc., to reduce processing costs and pressure on the environment , The effect of meeting the requirements of fashion elements and reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Select two groups of 340g / m 2 60 (50kg) of pure cotton indigo denims are put into 630 pounds of industrial washing machines, and the pumice stone milling process and the yeast grinding process using the environmental protection biological coarse flower enzyme preparation of the present invention are used as comparative tests respectively. They are:

[0035] (1) Stone grinding process:

[0036] ①Technical process: amylase desizing—washing—stone milling—washing—drying

[0037] ② 100kg of natural water-washed pumice is subjected to stone grinding treatment under the technological conditions shown in Table 2.

[0038] Table 2 Stone grinding process conditions

[0039] Process conditions

temperature

bath ratio

pH

time

stone mill

45℃

1∶2

6.5~7

30min

[0040] (2) Fermentation process of environmental protection biological crude flower enzyme preparation:

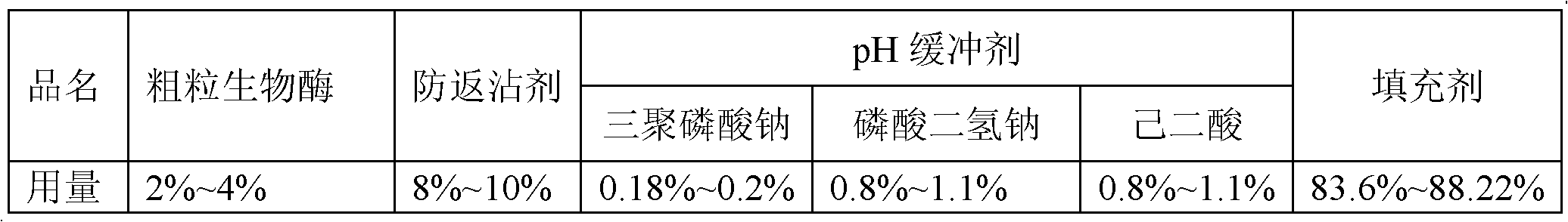

[0041] ①The formula of environmental-friendly biologic...

Embodiment 2

[0052] Select two groups of 340g / m 2 60 (50kg) of pure cotton indigo denims are put into 630 pounds of industrial washing machines, and the pumice stone milling process and the yeast grinding process using the environmental protection biological coarse flower enzyme preparation of the present invention are used as comparative tests respectively. They are:

[0053] (1) Stone grinding process:

[0054] ①Technical process: amylase desizing—washing—stone milling—washing—drying

[0055]② 100kg of natural water-washed pumice is subjected to stone grinding treatment under the technological conditions shown in Table 2.

[0056] (2) Fermentation process of environmental protection biological crude flower enzyme preparation:

[0057] ①The formula of environmental-friendly biological coarse flower enzyme preparation: coarse-grained biological cellulose original enzyme 4%, anti-restaining agent ECO10%, 0.2% sodium tripolyphosphate, sodium dihydrogen phosphate 1%, adipic acid 1%, sodium...

Embodiment 3

[0068] Select two groups of 340g / m 2 60 (50kg) of pure cotton indigo denims are put into 630 pounds of industrial washing machines, and the pumice stone milling process and the yeast grinding process using the environmental protection biological coarse flower enzyme preparation of the present invention are used as comparative tests respectively. They are:

[0069] (1) Stone grinding process:

[0070] ①Technical process: amylase desizing—washing—stone milling—washing—drying

[0071] ② 100kg of natural water-washed pumice is subjected to stone grinding treatment under the technological conditions shown in Table 2.

[0072] (2) Fermentation process of environmental protection biological crude flower enzyme preparation:

[0073] ①The formula of environmental protection biological coarse flower enzyme preparation: coarse-grained biological cellulose original enzyme 3%, anti-restaining agent ECO 10%, sodium tripolyphosphate 0.2%, sodium dihydrogen phosphate 1%, adipic acid 1%, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com