Gas production and water production section testing method of coal bed gas well and instrument

A test instrument and technology for coalbed methane wells, which are applied in the directions of measurement, earthwork drilling, wellbore/well components, etc., to achieve the effects of reducing influence, high precision, and increasing flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

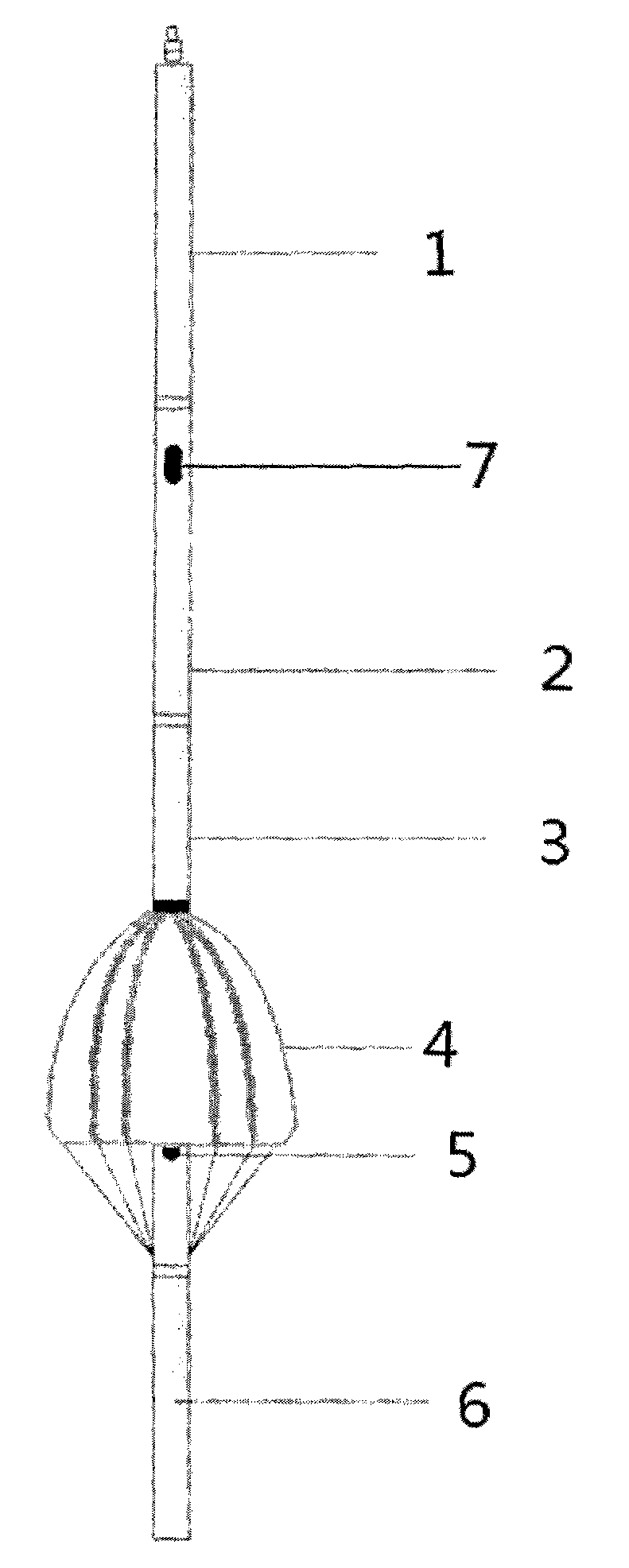

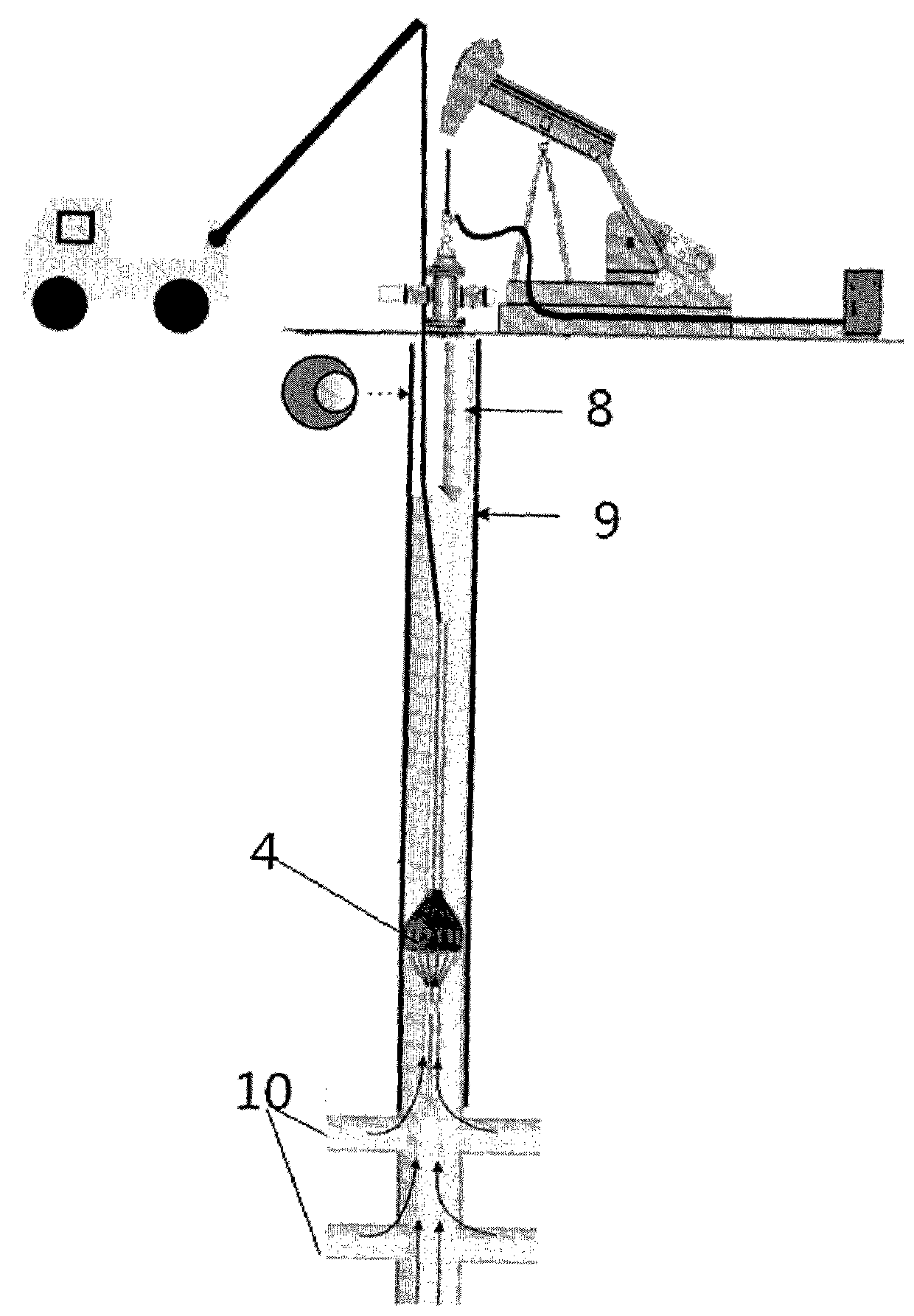

[0053] Embodiment 1: The specific example of the test method for the current collection method is as follows

[0054] (1) Carry out a simulated coalbed methane well test experiment for the capacitance water content meter

[0055] Aiming at the gas-liquid two-phase flow, the feasibility experiment study was carried out indoors with a piezoresistive flowmeter. The sensor adopts a flow collection scheme, and all the fluid in the wellbore flows through the piezoresistive flowmeter through the flow collection umbrella. During the experiment, nitrogen and water were used as the medium. First keep the flow of water at 3m respectively 3 / d, 5m 3 / d, 10m 3 / d, 20m 3 / d remains unchanged, gas volume gradually increases, ranging from 50m 3 / d~2000m 3 / d to record the change in instrument response. Experimental results such as Figure 5 As shown, the abscissa in the figure represents the gas flow, and the ordinate is the response value of the instrument. It can be seen from the ...

Embodiment 2

[0072] Embodiment 2: The test example of the non-current collection method is as follows:

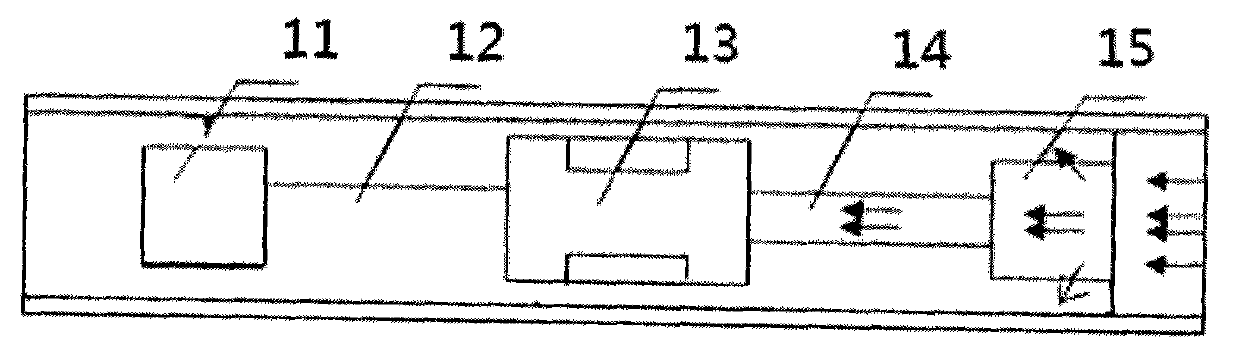

[0073] The quantitative test instrument is a differential pressure density meter, and the dynamic experimental research is carried out indoors with the differential pressure density meter. During the experiment, keep the flow of water at 3m 3 / d, 5m 3 / d, 10m 3 / d, 15m3 / d, 20m 3 / d remains unchanged, gas volume gradually increases, ranging from 50m 3 / d~2000m 3 / d to record the change in instrument response. According to the experimental data Figure 16 , the abscissa in the figure is the gas phase flow rate, the ordinate is the instrument response, and different curves represent different water flow rates. It can be seen from the figure that the response of the instrument decreases with the increase of air volume, and in the case of low water volume, it is less affected by the water volume.

[0074] Measuring range of differential pressure density meter:

[0075] Air flow: (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com