Refuse incineration power generation process and refuse incineration power generation equipment

A technology for waste incineration and power generation equipment, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of increased drying difficulty, low power generation efficiency, high moisture content, etc., and achieve elimination of adverse effects and high power generation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

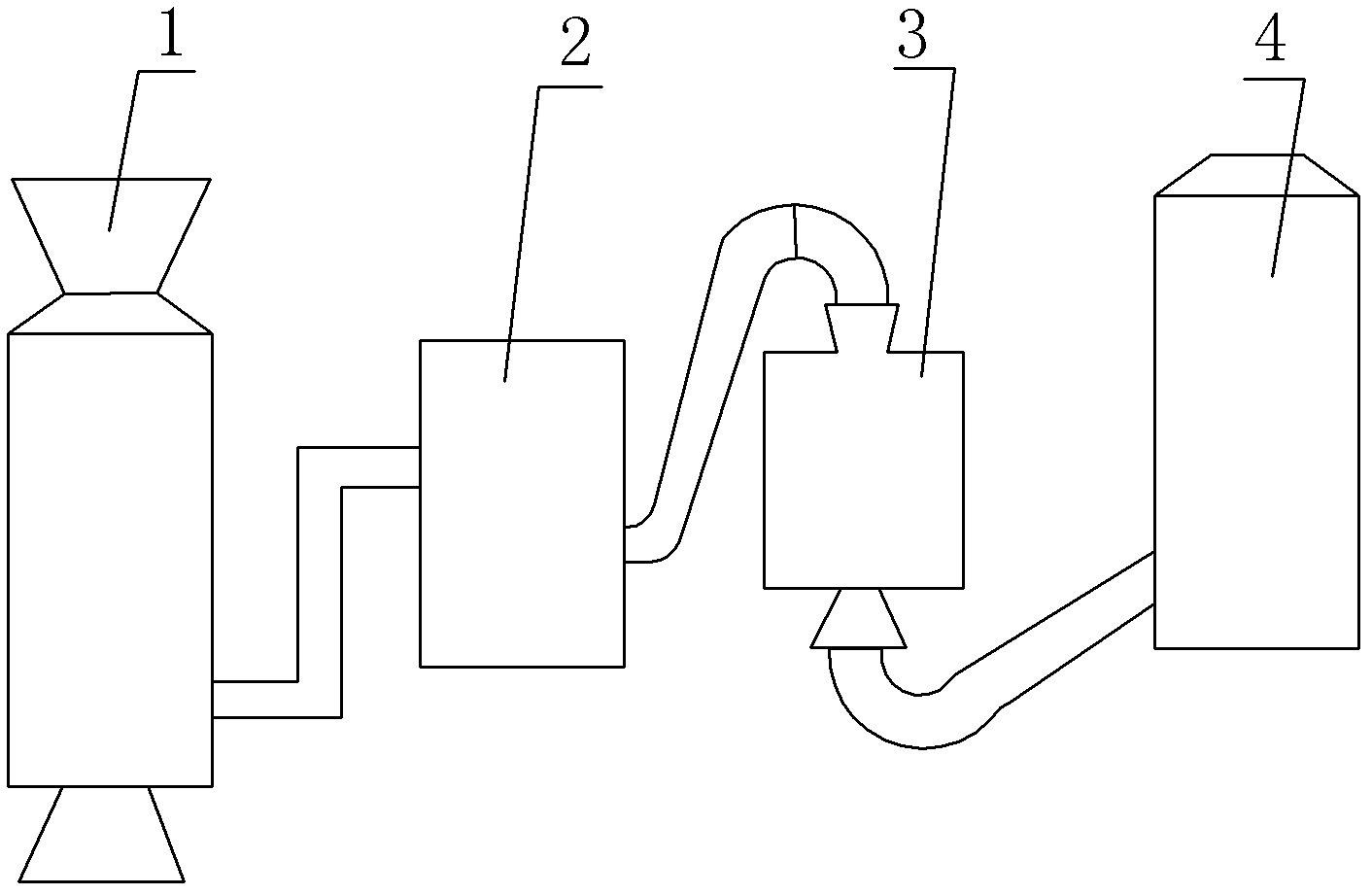

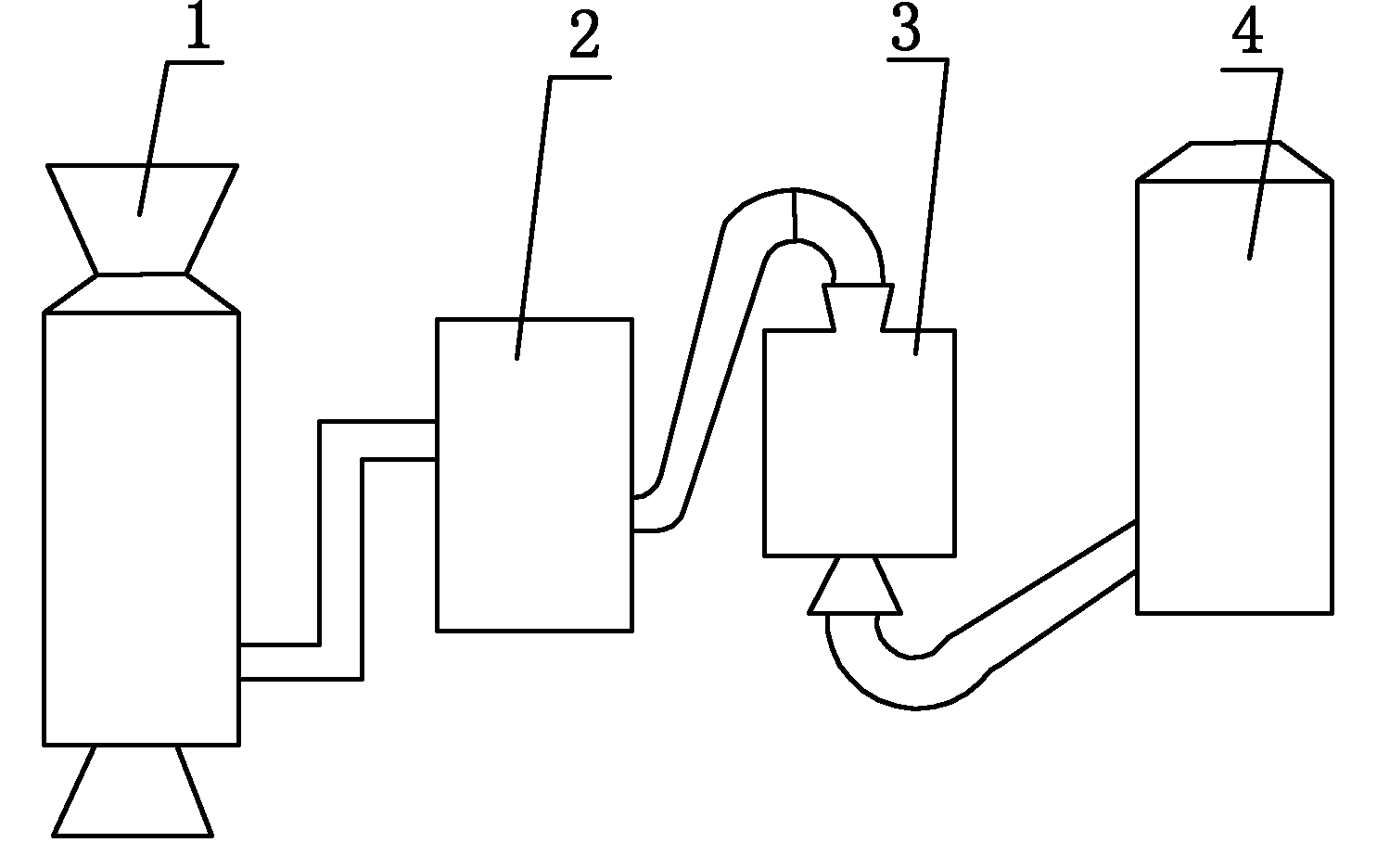

[0024] like figure 1 As shown, the waste incineration power generation equipment of the present invention includes the screening machine 1 of the model GTS-II unit produced by Shandong Zhucheng Guoyi Light Industry Machinery Co., Ltd., and the reversible anti-blocking machine of PCXK0808 produced by Weifang Hengxin Machinery Manufacturing Co., Ltd. Crusher 2, dryer 3 and thermal power incinerator 4. The outlet of the screening machine 1 is connected to the inlet of the crusher 2 through the conveying pipeline; the outlet of the crusher 2 is connected to the garbage inlet 3-4 of the dryer 3 through the conveying pipeline; The garbage discharge port 3-5 is connected on the feed port of the thermal power incinerator 4 through a conveying pipeline.

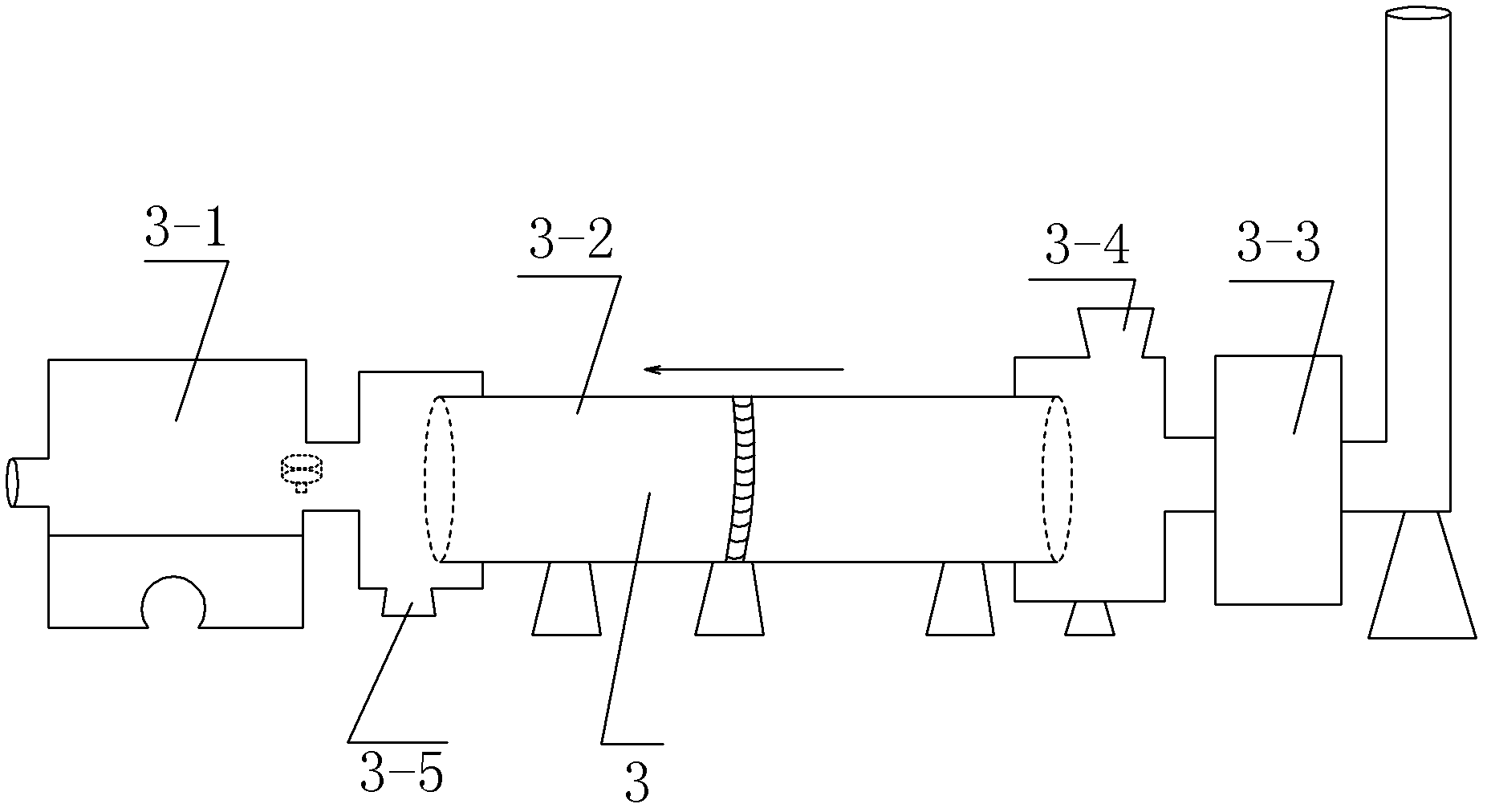

[0025] like figure 2 As shown, the dryer 3 includes a combustion furnace 3-1, a horizontally arranged drum 3-2 and a dust removal device 3-3, the combustion furnace 3-1 is connected with the dust removal device 3-3 through the drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com