Overburden water flowing fractured zone observation system and detection drilling method thereof

A water-conducting fissure zone and monitoring system technology, applied in seismology for well logging records, etc., can solve the problems of poor rigidity of the detection head, easy to produce misrecording or misrecording, and use, so as to avoid position errors and record Precise, less run-off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

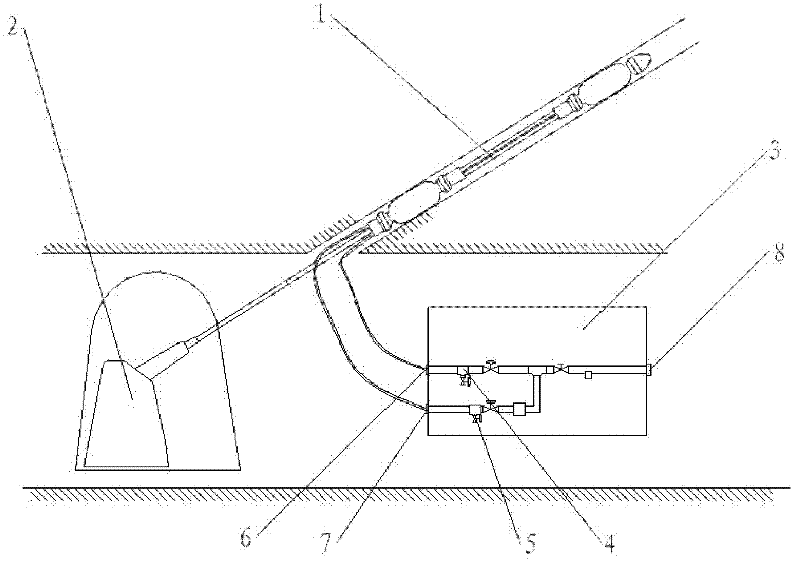

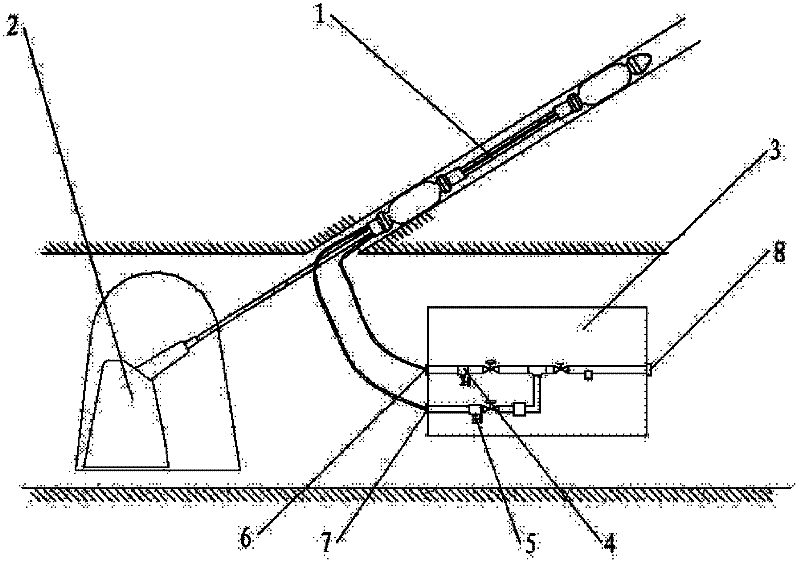

[0028] See attached figure 1 , which shows a monitoring system for a water-conducting fracture zone in overlying rock, including a drilling rig, a detection drilling device and a water injection control part.

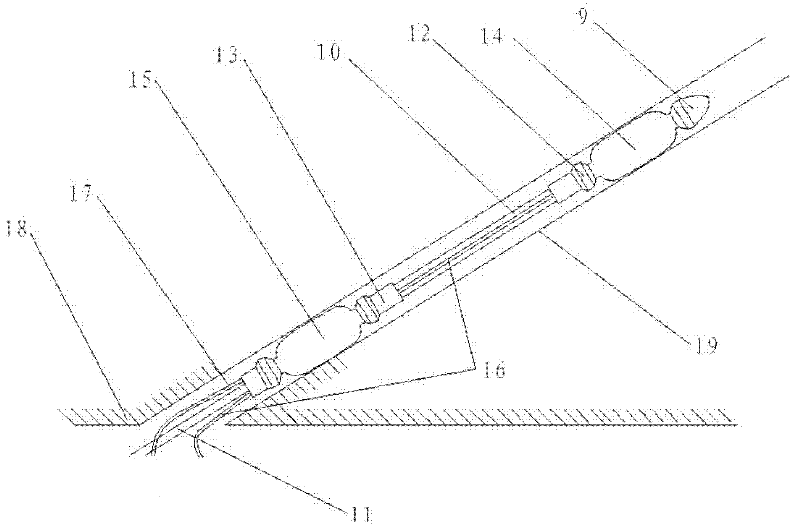

[0029] See attached figure 2 The detection and drilling device of the overburden water guiding fracture zone monitoring system includes a drill bit, a drill pipe and a connecting handle. The drill bit, drill pipe and connecting handle are all of solid structure. The drill bit is connected to the drill pipe through the first The connector is connected to the connection handle, where the drill bit can be a common coal seam drill bit, and the connection handle is used to connect the drilling machine. The diameter of the drill pipe is generally smaller than the minimum diameter of the first connector and the second connector, that is, it is screwed into the first connection connector and the second connector. The first connector and the second connector have ribs, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com