Environment-friendly mid-voltage fire resistant cable

A kind of fire-resistant cable, environment-friendly technology, applied in the direction of power cables with shielding layer/conductive layer, etc., can solve the problem of difficult performance uniformity and stability control of ceramic silicone rubber materials, insufficient protection of internal insulating cores, Complicated production process and other issues, to achieve the effects of good air permeability, protection from damage, and excellent economic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

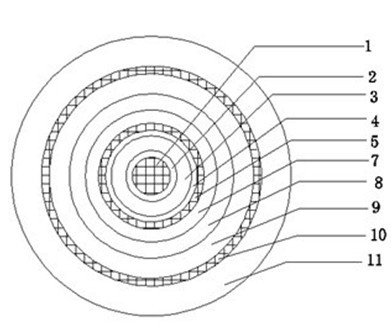

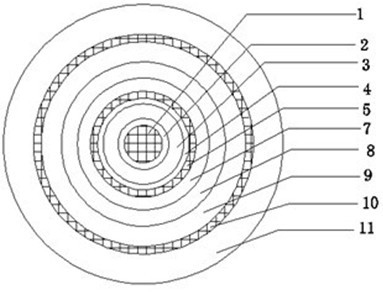

[0032] Such as figure 1 As shown, an environment-friendly medium-voltage fire-resistant cable according to the present invention has an aluminum alloy conductor 1 in the middle, and a conductor shielding layer 2, a cross-linked poly Vinyl insulating layer 3, insulating shielding layer 4, metal shielding layer 5 is arranged outside the insulating shielding layer 4; aluminum alloy conductor 1, conductor shielding 2, insulating layer 3, insulating shielding layer 4 and metal shielding layer 5 constitute an insulating wire core; The wire core is wrapped with a layer of inorganic heat insulation layer 7, and the heat insulation layer 7 is extruded with a low-smoke halogen-free flame-retardant polyolefin inner sheath 8, and the inner sheath 8 is wrapped with an inorganic fiber layer 9; the heat insulation layer 7. The inner protective layer 8 and the inorganic fiber layer 9 constitute a composite fire-resistant and heat-insulating layer; the composite fire-resistant and heat-insulat...

Embodiment 2

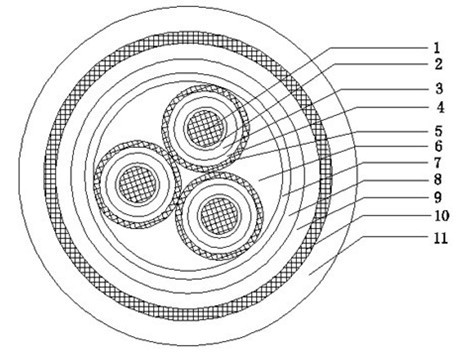

[0034] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that: one insulated wire core is changed to three, and the three insulated wires are twisted into a cable core, and filling material 6 is provided in the gap and surface of the cable core.

[0035] A composite fire-resistant and heat-insulating layer composed of an outer sheath layer 11, copper strips, copper alloy strips, galvanized steel strips or stainless steel strips. Under the combined action, the fire resistance and flame retardancy of medium voltage cables can meet the requirements of Class A fire resistance and Class A flame retardancy. When burning, they have low smoke, non-toxicity and excellent environmental protection performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com