Solar cell structure with wide spectrum high absorption and manufacturing method thereof

A technology of solar cells and manufacturing methods, which is applied in the manufacture of circuits, electrical components, and final products, and can solve the problems of narrow absorption spectrum and low absorption rate, and achieve the effects of low cost, improved absorption, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

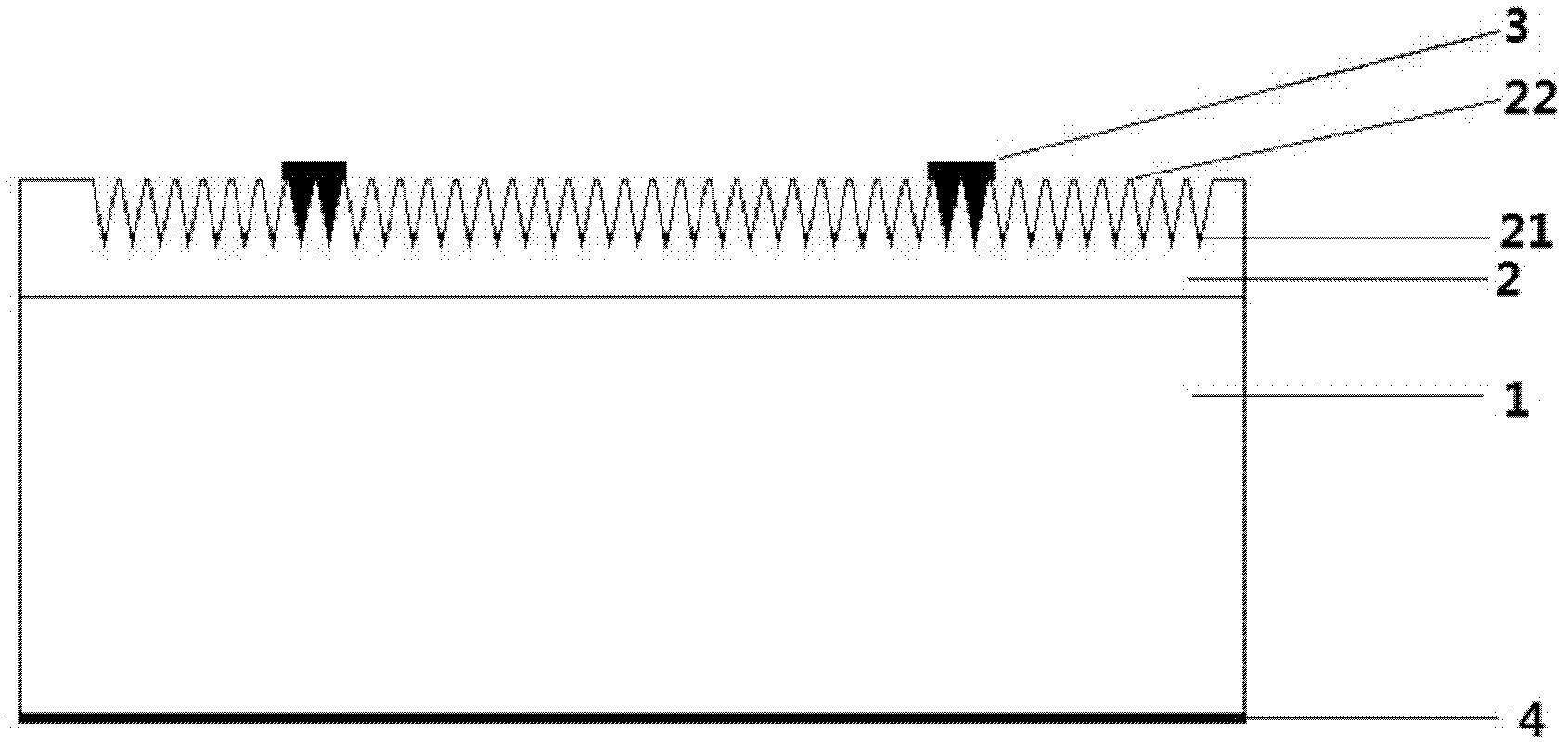

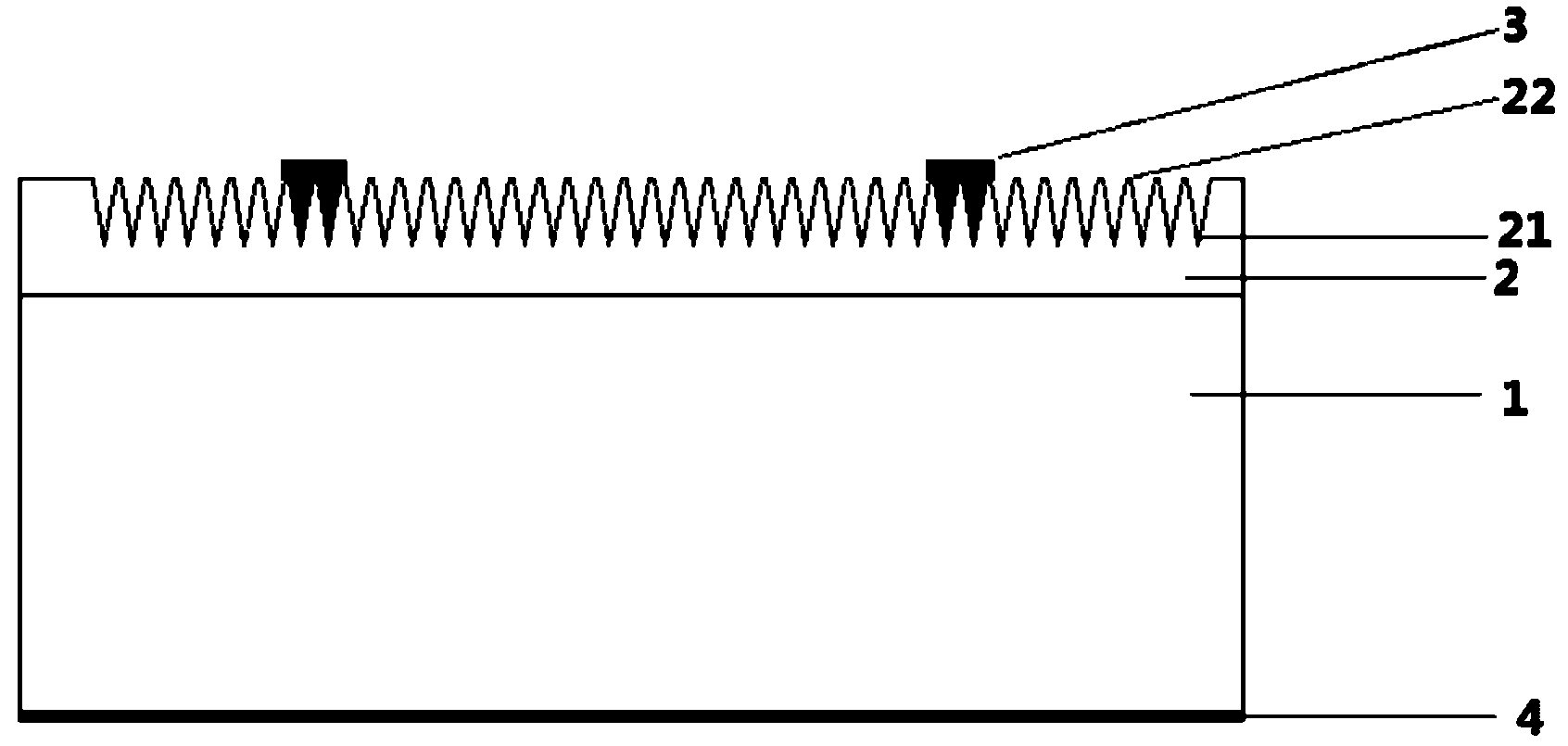

[0026] see figure 1 As shown, the present invention provides a broad-spectrum high-absorption solar cell structure, comprising:

[0027] A p-type or lightly doped n-type silicon layer 1, the silicon substrate has a (100) crystal orientation, its thickness is 200 to 600 μm, and its resistivity is 0.1 to 10 Ω·cm;

[0028] A chalcogenide-doped layer 2, the chalcogenide-doped layer 2 is silicon material doped with chalcogenides, the chalcogenide-doped layer 2 is fabricated on the p-type or lightly doped n-type silicon layer 1 , the doping concentration of the chalcogenide doped layer 2 is 10 17 to 10 20 cm -3 , the surface of the chalcogenide-doped layer 2 is fabricated with an array-like continuous cone structure 22, the height of the cone structure 22 is 0.1 μm to 10 μm, the diameter is 20 nm to 5 μm, and the distance between the apexes of each cone is 20nm to 5μm, the bottom of the gap between the pointed cone structures 22 is deposited silver nanoparticles 21, and the diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com