Method for enhancing heat exchange of free surface array jet system

An array jet, free technology, applied in the direction of cooling/ventilation/heating transformation, can solve the problem of low heat exchange performance, and achieve the effect of improving heat exchange capacity, high heat exchange effect, and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

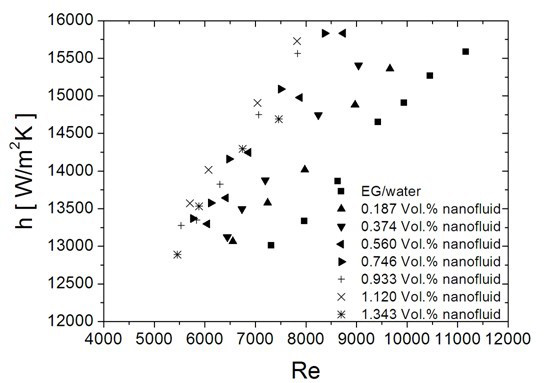

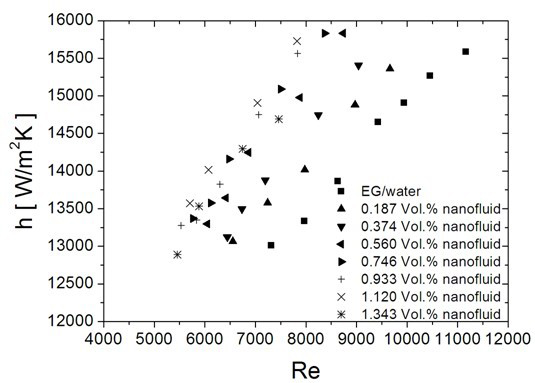

[0027] 1. Measure 1.5L each of ethylene glycol and deionized water, and mix them well to make a 1:1 ethylene glycol-water solution;

[0028] 2. Weigh 120g of metal copper nanoparticles with an average diameter of 50nm, add it to ethylene glycol-water solution, put it into an ultrasonic device for ultrasonication for 4h, and perform mechanical stirring at the same time to prepare copper-ethylene glycol with a volume fraction of 0.56%. Glycol-water nanofluid, which is a two-step method for preparing nanofluid;

[0029] 3. Optimize the system, heat-preserve the inside of the system tube, adjust the heat exchange equipment, select the diameter of the jet hole to be 1.5mm, the S / D to be 3, and the H / D to be 7; the surface is grooved, the groove depth is 0.5mm, and the groove width is 0.5mm , the groove spacing is 0.5mm, adjust the position of the jet hole to ensure that the array jet hole is facing the center of the heat exchange surface;

[0030] 4. Add the prepared nanofluid int...

Embodiment 2

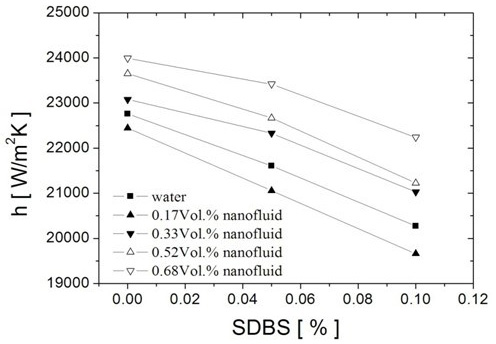

[0033] 1. Measure 3L of deionized water, weigh 38g of metal copper nanoparticles with an average diameter of 25nm, add it to deionized water, and add sodium dodecylbenzenesulfonate with a mass fraction of 0.05% as a dispersant at the same time, put it in Ultrasonic 4h in ultrasonic equipment, carry out mechanical stirring simultaneously, prepare the copper-water nanofluid that volume fraction is 0.17%;

[0034] 2. Optimize the system, heat-preserve the inside of the system tube, adjust the heat exchange equipment, select the jet hole diameter as 3.0mm, S / D as 1.5, and H / D as 5; the surface is grooved, the groove depth is 1.0mm, and the groove width is 0.5mm , the groove spacing is 0.5mm, adjust the position of the jet hole to ensure that the array jet hole is facing the center of the heat exchange surface;

[0035] 3. Add the prepared nanofluid into the experimental system, adjust the experimental temperature to 21°C, and the flow rate of the heat exchange working fluid to 0.2...

Embodiment 3

[0038] 1. Measure 3L of deionized water, weigh 79g of copper oxide nanoparticles with an average diameter of 50nm, add it to deionized water, and add 0.1% sodium dodecylbenzenesulfonate as a dispersant at the same time, put it in Ultrasonic 4h in ultrasonic equipment, carry out mechanical stirring simultaneously, prepare the copper oxide-water nanofluid that volume fraction is 0.33%;

[0039] 2. Optimize the system, heat-preserve the inside of the system tube, adjust the heat exchange equipment, select the jet hole diameter as 0.5mm, S / D as 10, and H / D as 15; the surface is grooved, the groove depth is 1.5mm, and the groove width is 2.0mm , the groove spacing is 2.0mm, adjust the position of the jet hole to ensure that the array jet hole is facing the center of the heat exchange surface;

[0040]3. Add the prepared nanofluid into the experimental system, adjust the experimental temperature to 20°C, the flow rate of the heat exchange working medium is 0.197m3 / h, and the simulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com