Flexible semiconductor device and manufacturing method therefor

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, organic semiconductor devices, etc., can solve problems such as hindering high-speed operation, and achieve reduction of parasitic capacitance and leakage current, high-performance productivity, and improvement of Effects of Features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

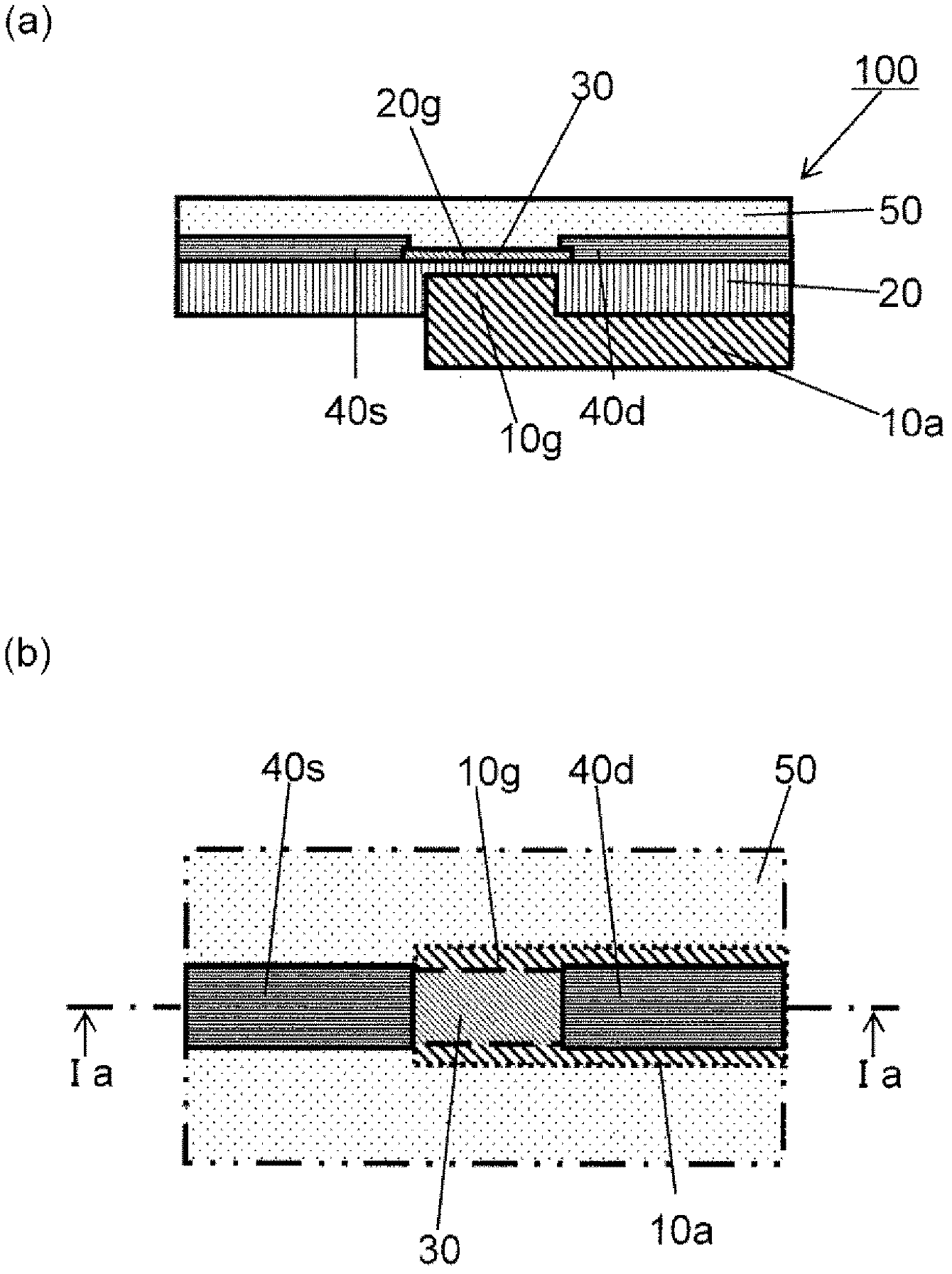

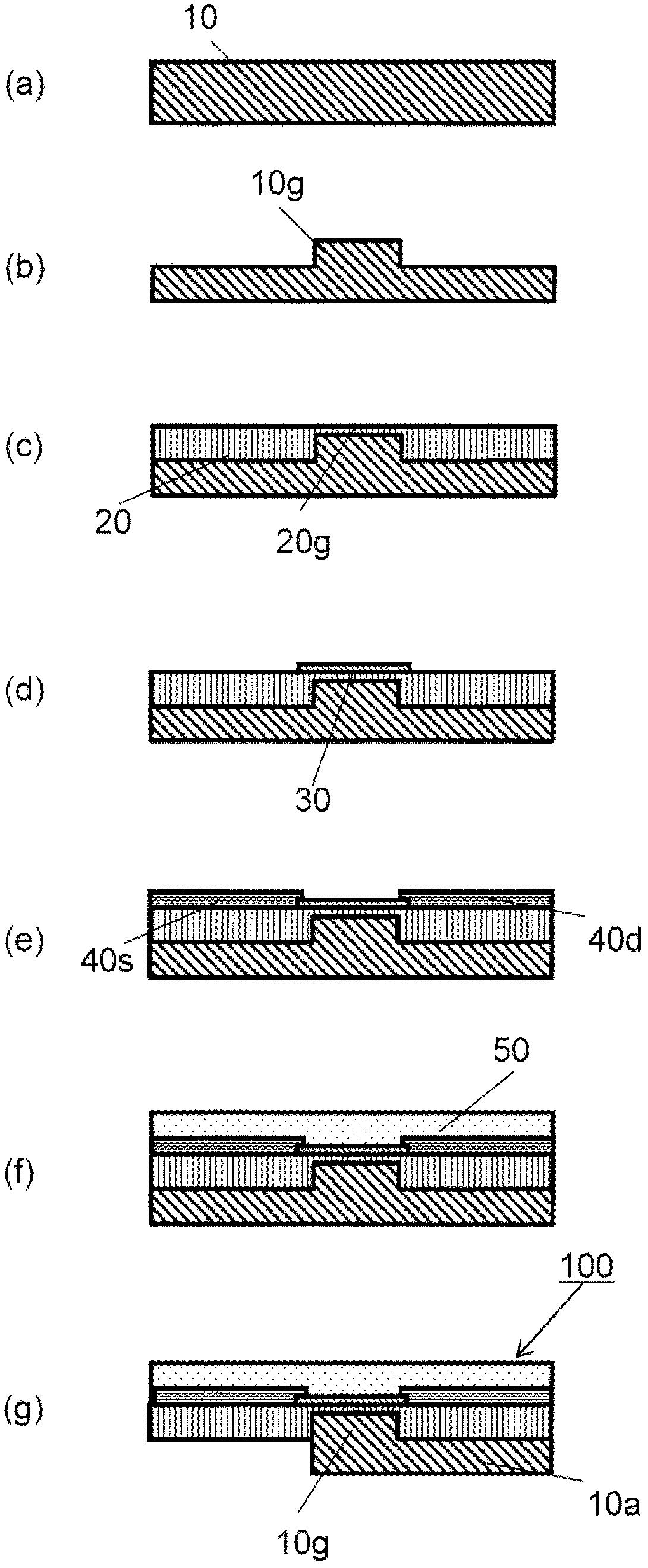

[0075] refer to figure 1 (a) and (b) describe the flexible semiconductor device 100 according to Embodiment 1 of the present invention.

[0076] figure 1 (b) is a schematic diagram of the upper surface of the flexible semiconductor device 100, figure 1 (a) to represent figure 1 (b) Schematic cross-sectional view of the Ia-Ia section.

[0077] The flexible semiconductor device 100 includes the following parts: an insulating film 20; a source electrode 40s and a drain electrode 40d formed on the insulating film 20; a semiconductor layer 30; and the insulating film 20 also functions as a gate insulating film. A gate insulating film 20g, a TFT structure composed of a gate electrode 10g, and a lower wiring pattern layer 10a drawn out from the gate electrode 10g and functioning as a wiring portion.

[0078] The sealing layer 50 also functions as a base material supporting the TFT structure, and is preferably made of a flexible resin material that is bendable even after curing. ...

Embodiment approach 2

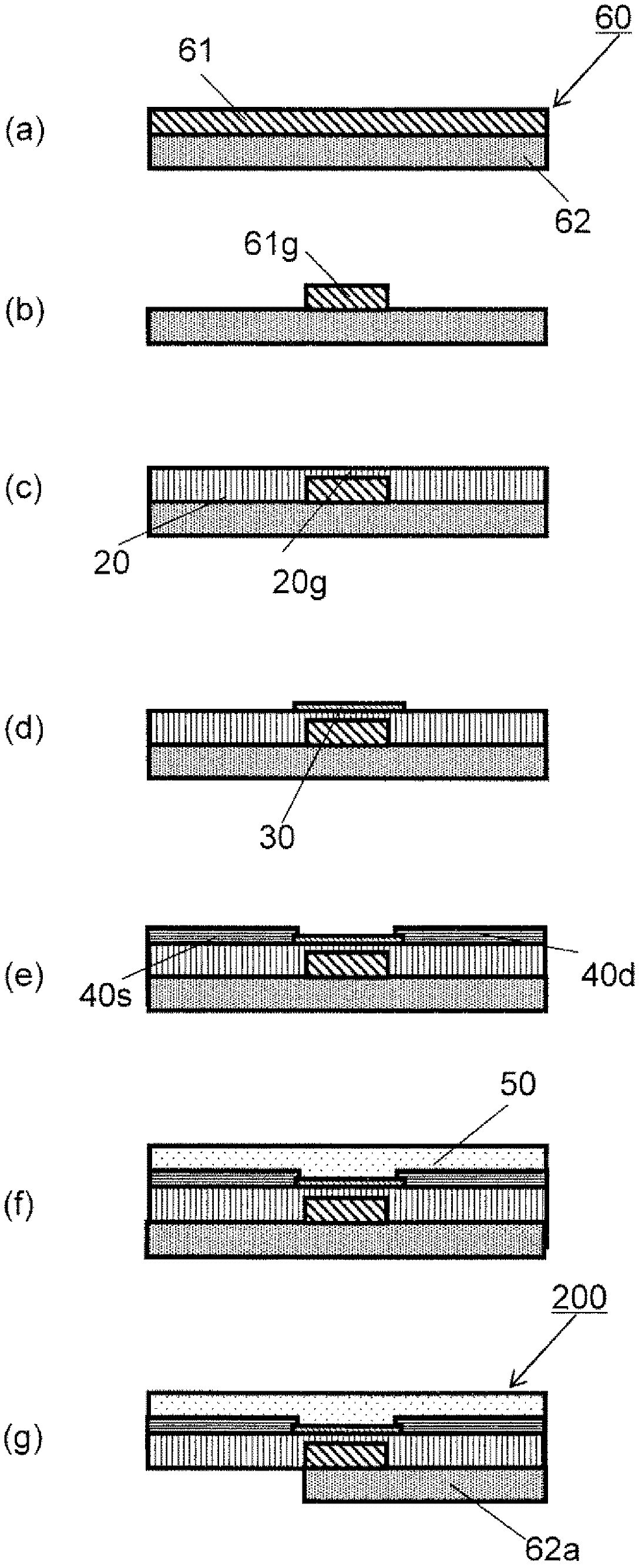

[0108] image 3 The structure of the flexible semiconductor device 200 related to one embodiment of the present invention is shown. In this second embodiment, the point of difference from the above-mentioned first embodiment is that a multilayer metal foil having a structure of two or more layers of different metal materials is used. That is, the prepared metal foil has a multilayer structure, and the gate electrode 10g and the lower wiring pattern layer 10a are formed of different metal materials.

[0109] refer to image 3 (a)-(g) demonstrate an example of the manufacturing process of this Embodiment 2. In addition, description of portions overlapping with Embodiment 1 will be omitted except for matters particularly mentioned.

[0110] First, if image 3 As shown in (a), the multilayer metal foil 60 in which the first metal layer 61 and the second metal layer 62 are sequentially laminated is prepared. The metal constituting the first metal layer 61 and the second metal ...

Embodiment approach 3

[0116] Figure 4 The configuration of a flexible semiconductor device 300 according to an embodiment of the present invention is shown. This third embodiment differs from the first embodiment described above in that the second insulating film 21 is formed together with the insulating film 20 in the concave portion formed in the metal foil 10 . refer to Figure 4 (a)-(h) An example of this manufacturing process is demonstrated. In addition, description of portions overlapping with Embodiment 1 will be omitted except for matters particularly mentioned.

[0117] First, if Figure 4 As shown in (a), the metal foil 10 is prepared (produced, purchased, etc.). In this embodiment, the metal foil 10 can use the SUS foil of thickness 70 micrometers, for example.

[0118] Next, if Figure 4 As shown in (b), by etching the metal foil 10 , protrusions serving as gate electrodes or capacitor electrodes and other recesses are formed on the surface of the metal foil 10 .

[0119] Next,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com