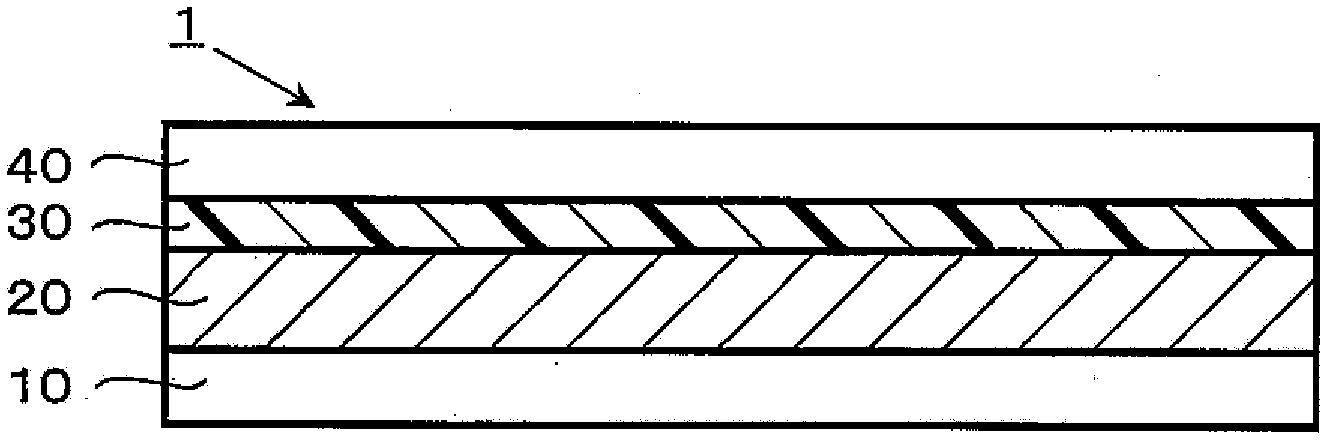

Dye-sensitized solar cell, dye-sensitized solar cell module, and coating liquid for forming electrolyte layer

一种太阳能电池、色素敏化的技术,应用在涂布液领域,能够解决初始转换效率或耐久性不充分、电解质经时稳定性降低、碘化锂潮解性高易劣化等问题,达到光电转换效率高、经时稳定性提高、实现低价格化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

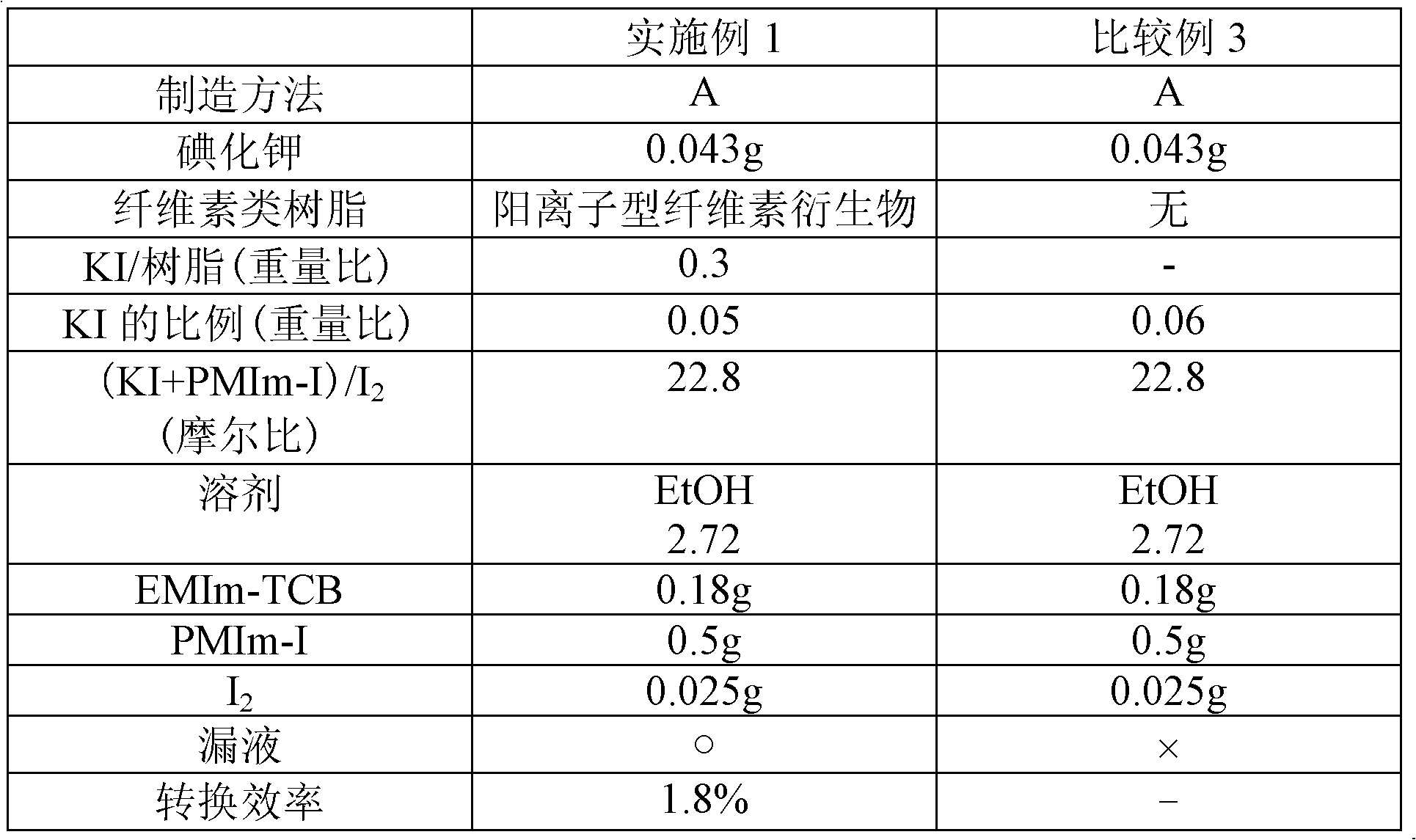

Embodiment 1

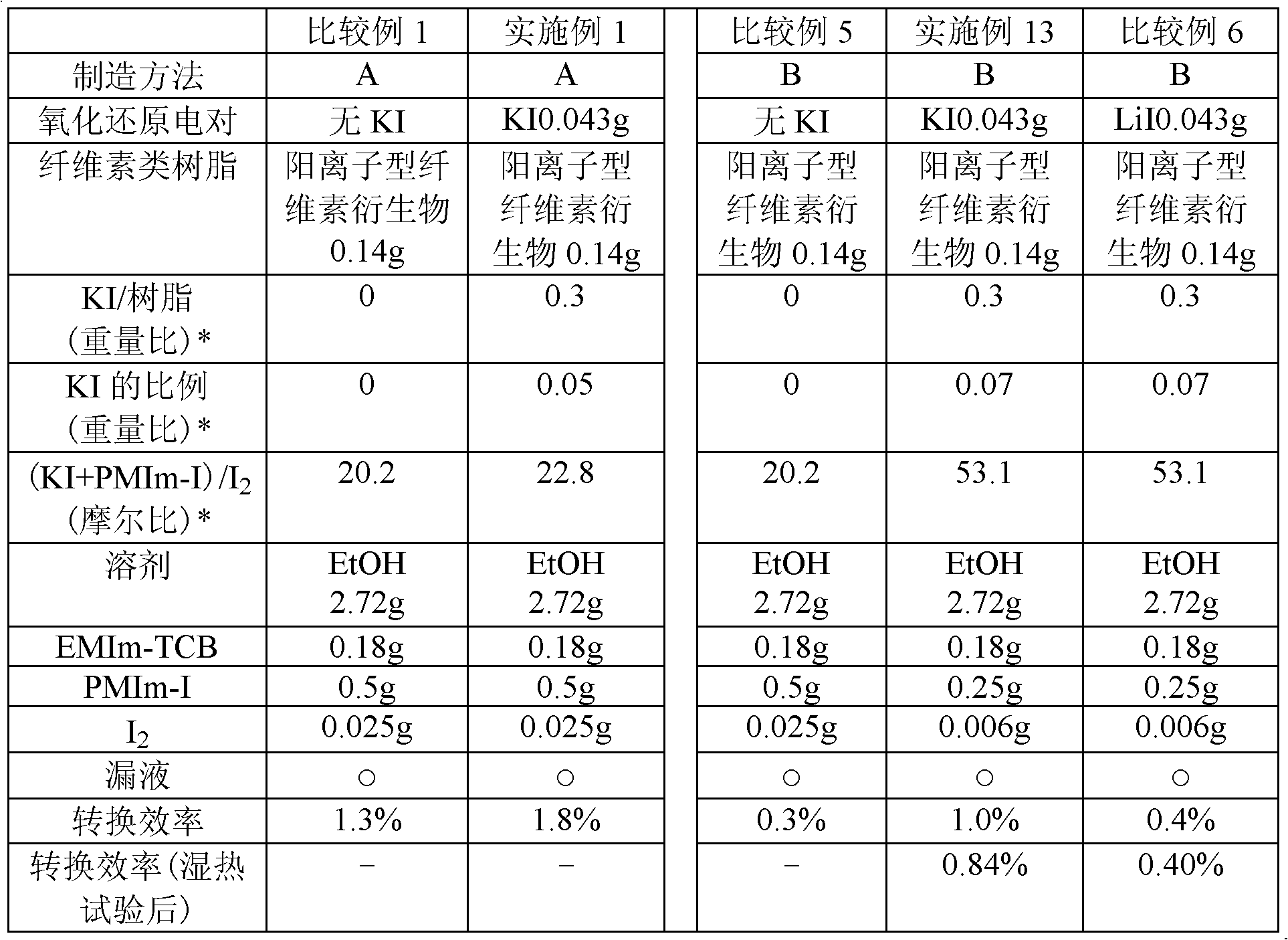

[0103] Using 3-chloro-2-hydroxypropyltrimethylammonium chloride as a cationic cellulose derivative, cationized cationic hydroxyethyl cellulose (manufactured by Daicel Chemical Co., Ltd.; Jielna-QH200) was dissolved in 2.72 g of methanol. ; The degree of substitution m=1.3, the ratio of cationization is -CH 2 CH 2 0.043 g of potassium iodide was added to a solution of 0.14 g of OH group, and stirred to dissolve it. Next, 0.18 g of 1-ethyl-3-methylimidazolium tetracyanoborate (EMIm-TCB), 1-propyl-3-methylimidazolium iodide (PMIm-I) were added to the solution. 0.5g, and I 2 0.025g, stir to dissolve. Accordingly, a coatable coating solution for forming an electrolyte layer was prepared.

Embodiment 2~13

[0105] A coating liquid for forming an electrolyte layer was prepared in the same manner as in Example 1 above except that the formulation was changed. The preparation amount of each component is as shown in Tables 3-5 below. In addition, the coating liquid of Example 13 is the same as that of Example 7. In addition, in the table, "the ratio of KI (weight ratio)" means the ratio of KI except the solvent to all the materials constituting the electrolyte layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com