Processing equipment and processing technique for poultry feather protein powder

A technology of feather protein powder and processing equipment, which is applied in feed, animal feed, animal feed, etc., can solve the problems of large energy consumption, long production cycle, and low drying efficiency, so as to ensure operation time and efficiency, and is conducive to environmental protection , the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

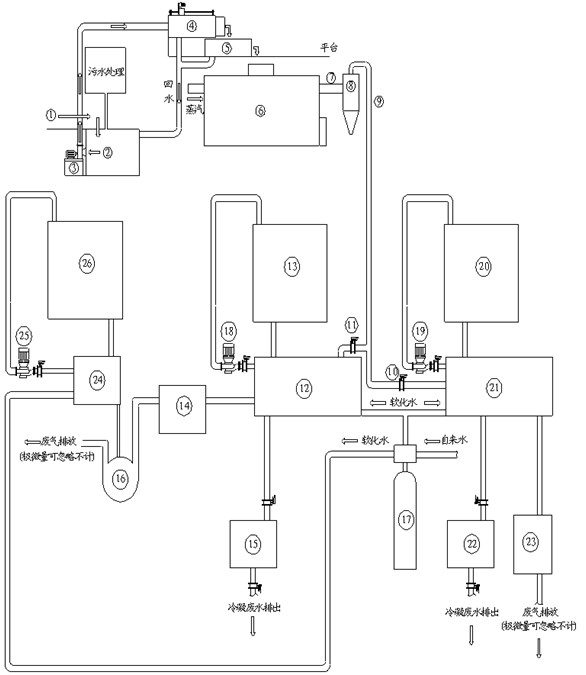

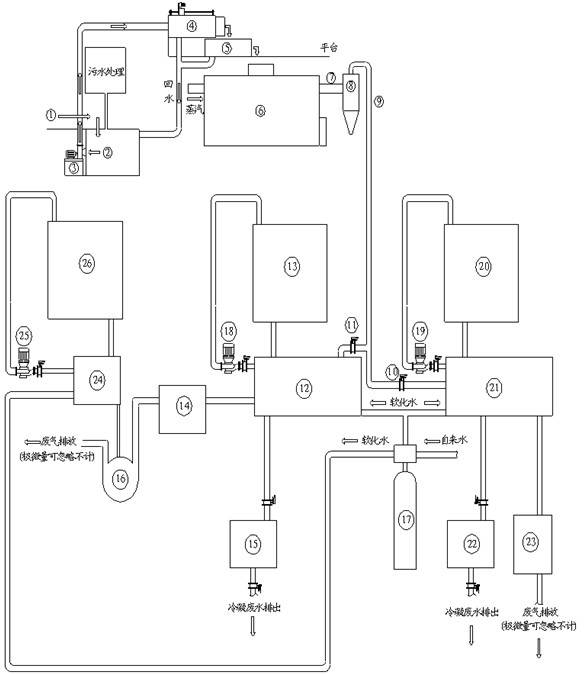

Embodiment 1

[0043] A kind of processing equipment reference of poultry feather protein powder of the present embodiment figure 1 , including a pretreatment system for rough processing of feathers and water, the pretreatment system is connected with the hydrolysis pressure relief system through the pipeline 9 and the first control valve 10, and the pretreatment system is connected with the vacuum drying system through the pipeline 9 and the second control valve 11 The demineralized water processor 17 connected with the hydrolysis pressure relief system and the vacuum drying system all provide demineralized water; the pretreatment system includes a hairy water pool 2 connected with the slaughter line 1, and the hairy water pool 2 passes through a side. The provided hair water pump 3 is connected to the upper feather water separator 4, and the output of the feather water separator 4 is connected to the lower high-efficiency squeezer 5, and the output of the high-efficiency squeezer 5 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com