Porous core-shell nano auriferous alloy and preparation method for same

A porous core and alloy technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of limited catalytic activity of single crystal core-shell metal nanostructures, achieve excellent catalytic performance, Strong reproducibility, simple and controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

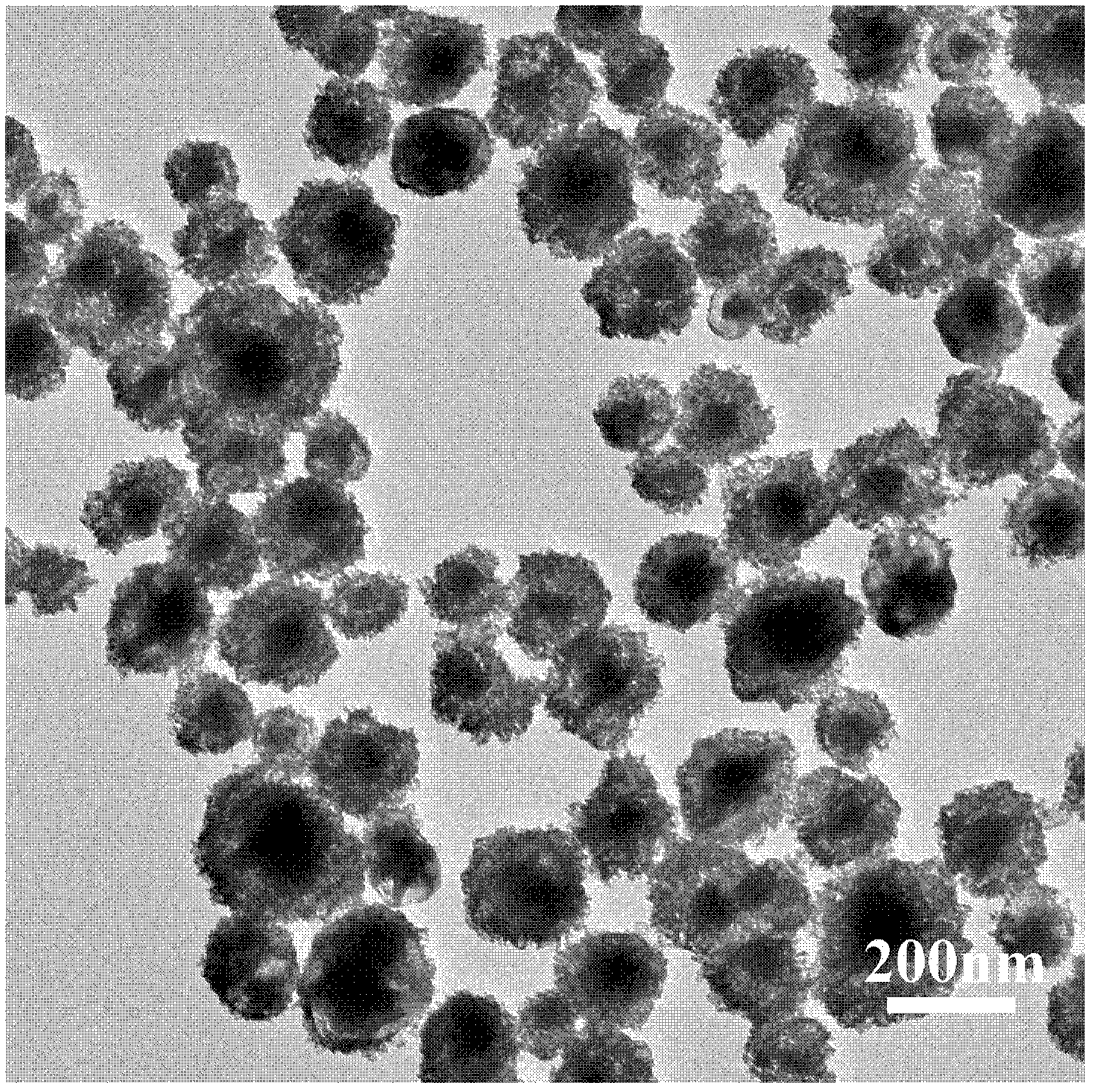

[0026] Weigh 1.2 mg of AuAg core-shell nanoparticles, disperse in 10 mL of deionized water, add 1 mL of 10.2 mmol / L HAuCl 2 The solution was left to stand for 2 hours in the dark at room temperature. Centrifuge the product, collect the precipitate, and wash it sequentially with ammonia water, deionized water, and absolute ethanol to prepare a porous Au-Au core-shell nanostructure, such as figure 1 As shown, the shell consists of Au nanoparticles with a thickness of about 35 nm.

Embodiment 2

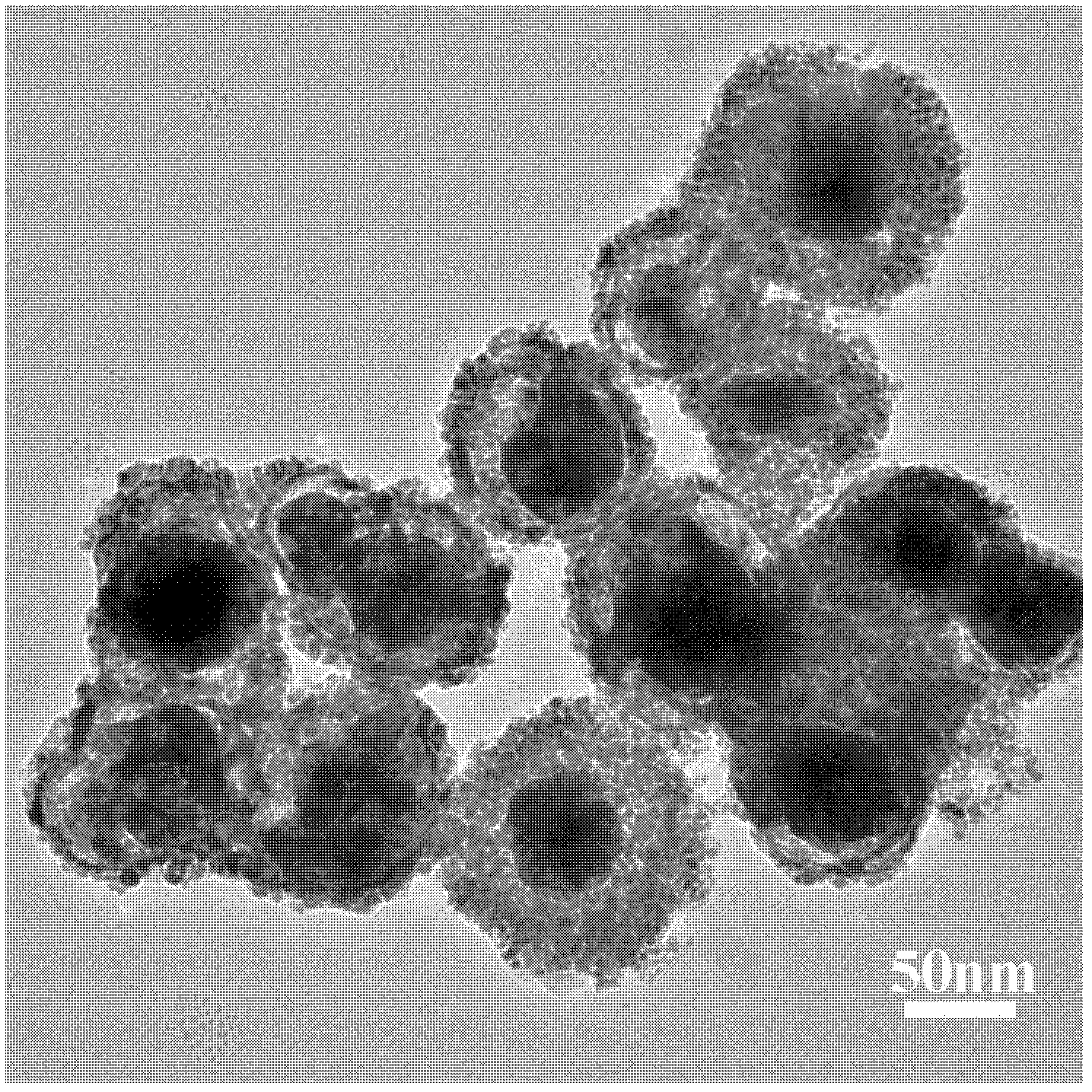

[0028] Weigh 2.4mg of AuAg core-shell nanoparticles, disperse in 15mL of deionized water, add 2mL of 13.5mmol / L H 2 PdCl 4 Aqueous solution, stand in the dark for 4 hours at room temperature. Centrifuge the product, collect the precipitate, and wash it sequentially with ammonia water, deionized water, and absolute ethanol to prepare a porous Au-Pd core-shell nanostructure, such as figure 2 As shown, the shell consists of Pd nanoparticles with a thickness of about 25 nm.

Embodiment 3

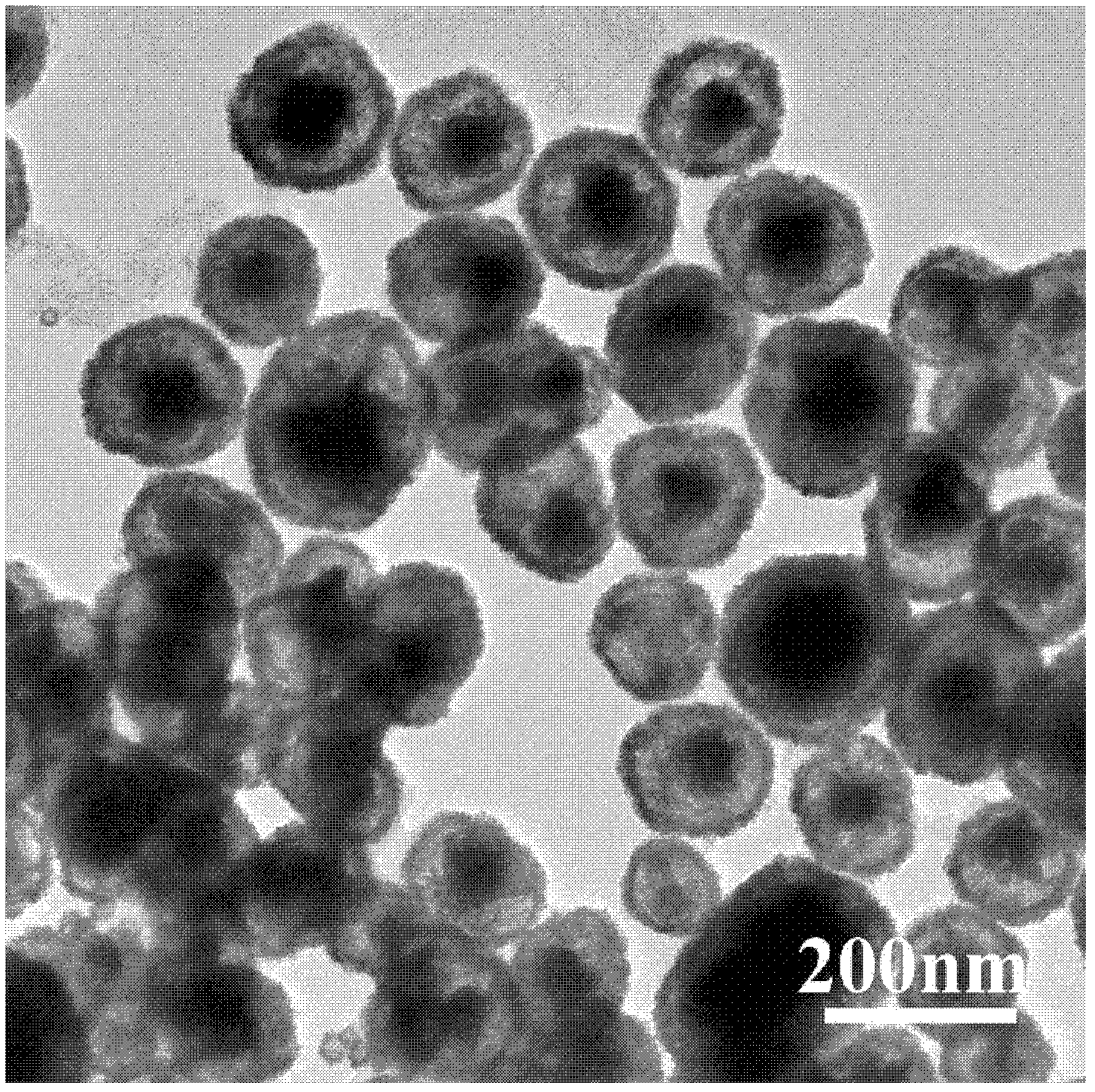

[0030] Weigh 1.5 mg of AuAg core-shell nanoparticles, disperse in 12 mL of deionized water, add 1.5 mL of K with a concentration of 18.5 mmol / L 2 PtCl 4 Aqueous solution, stand in the dark for 6 hours, the temperature is 60°C. Centrifuge the product, collect the precipitate, and wash it sequentially with ammonia water, deionized water, and absolute ethanol to prepare a porous Au-Pt core-shell nanostructure, such as image 3 As shown, the shell consists of Pt nanoparticles with a thickness of about 30 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com