Six-axis five-linked electrolytic grinding and polishing machine with planetary tracking sprayer

A technology of grinding and polishing machine and five linkages, applied in the field of grinding and polishing machines, can solve the problems of difficult surface processing, acid environment pollution, complicated programming, etc., and achieve high-precision electrolytic grinding, smooth surface and good consistency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

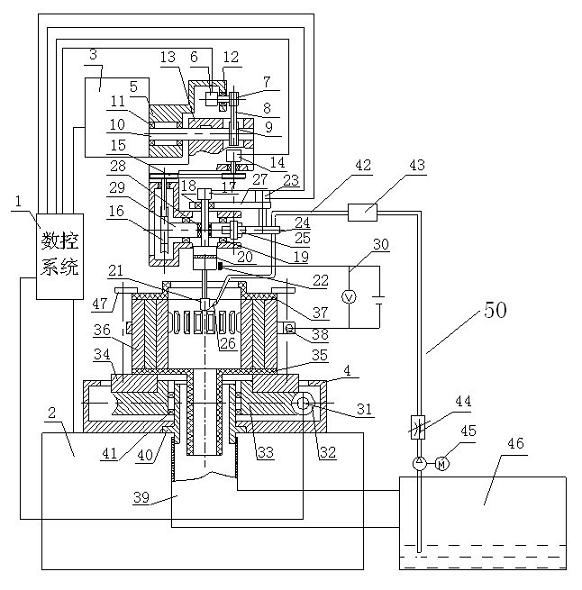

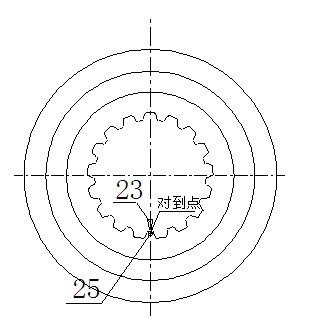

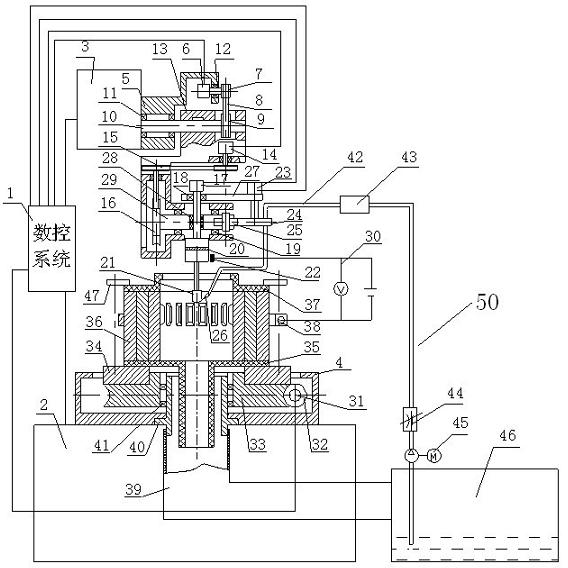

[0016] A planetary tracking nozzle six-axis five-linkage electrolytic polishing machine, see figure 1 , the polishing machine includes a control system 1, an X-Y axis moving table 2, a Z axis moving table 3, a rotating disk bracket 4, bracket A 5, bracket B 13, an electrolytic acid liquid planetary tracking mechanism 50 and a grinding head twenty one. The rotating disk bracket 4 controlling the C axis is installed on the X-Y axis moving table 2, and the bracket A controlling the A axis is installed on the Z axis moving table 3. A stepper motor A6, gear 7, synchronous toothed belt 8, gear 9, shaft 10, bearing 11 and bearing 12 are arranged on the bracket A5 to control the rotation of the A axis, driven by the CNC control system 1 and the stepper motor 6 , realize the rotation of table A. The bracket B13 is installed on the shaft 10, the stepping motor B14 for controlling the rotation of the B axis, the synchronous toothed belt 15, the gear, the worm mechanism 16, and the sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com