Wax-free grinding and polishing template with double inlaying layers

A double inlay and inlay layer technology, which is applied in the direction of grinding tools, can solve the problems of high replacement cost, large thickness deviation of silicon wafers, wax pollution, etc., and achieve the effects of improving polishing efficiency, reducing thickness deviation, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

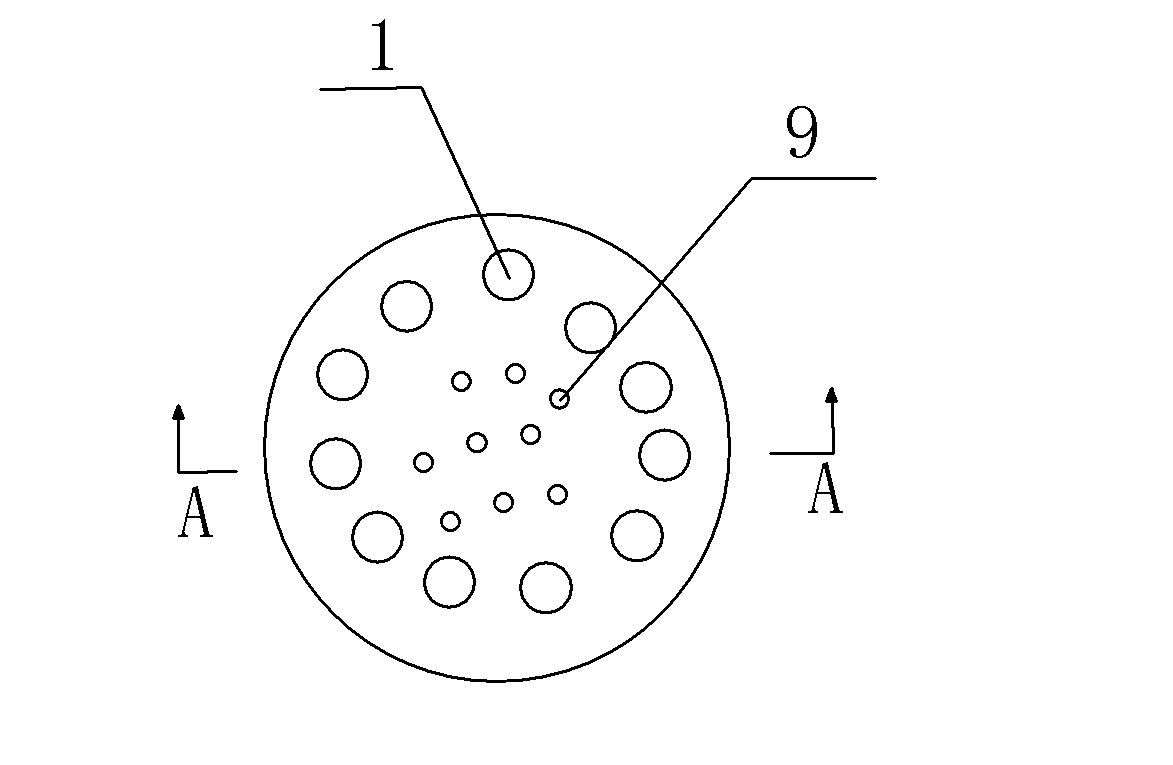

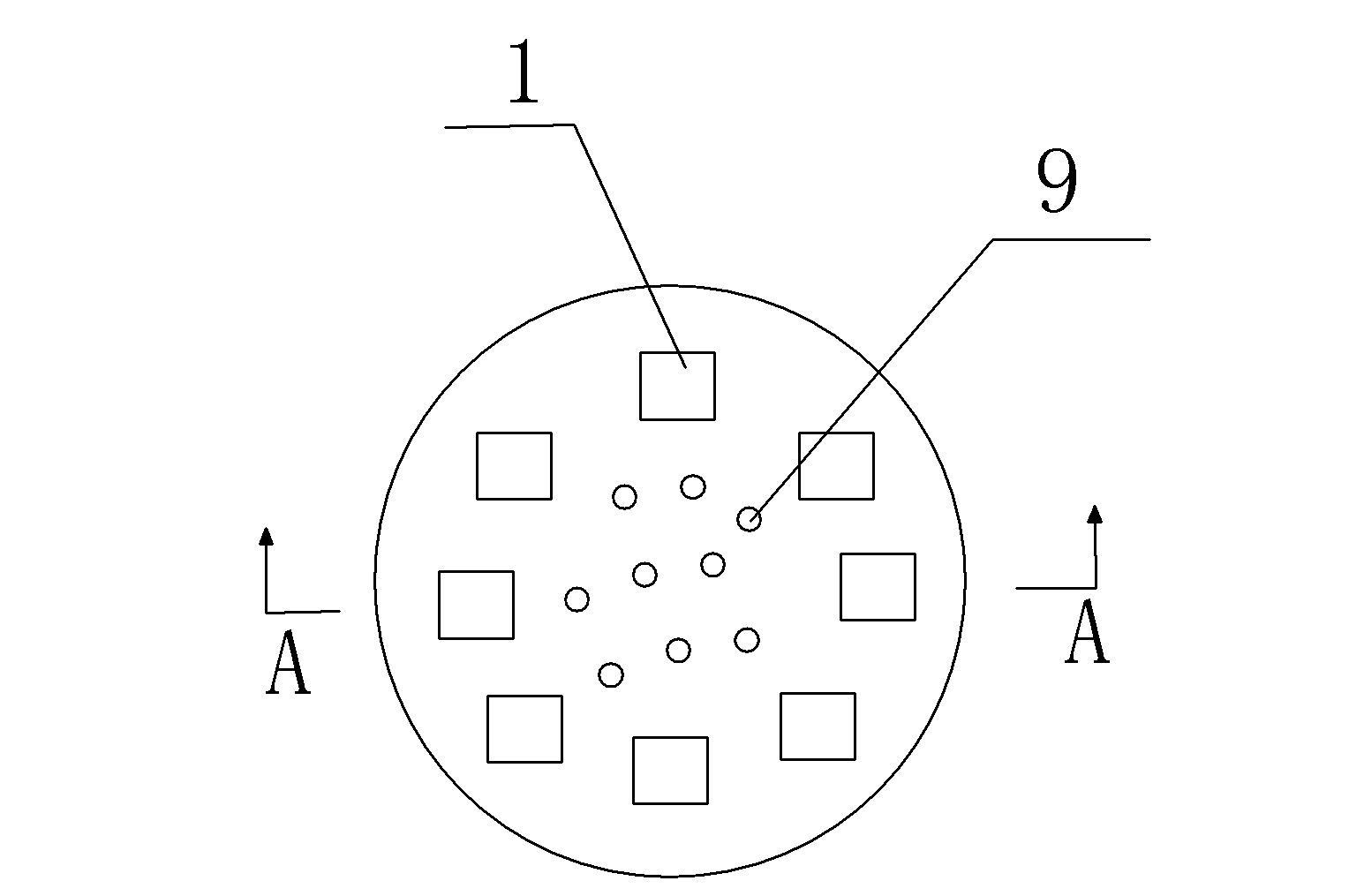

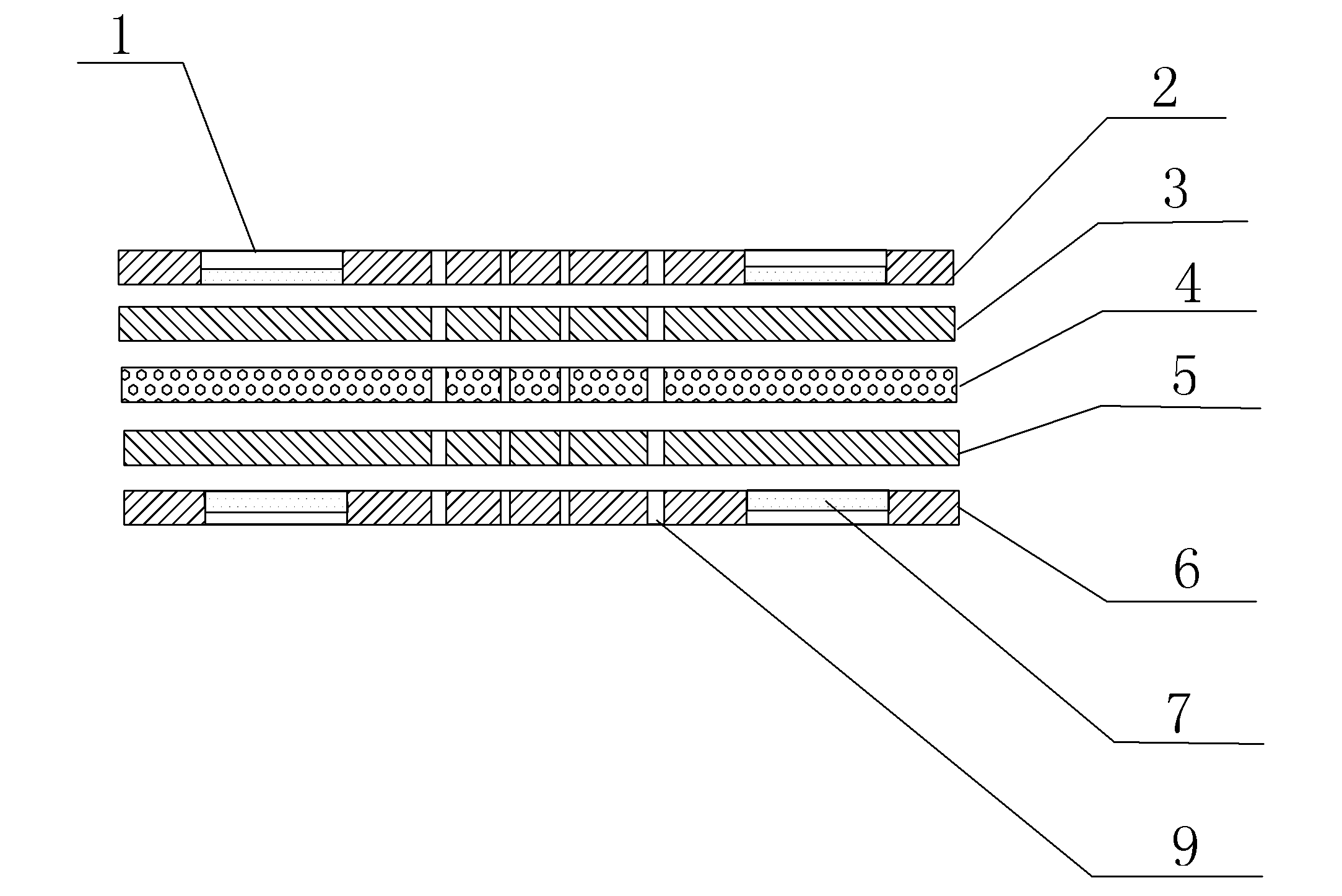

[0023] Such as figure 1 and figure 2 Shown: a double mosaic layer wax-free grinding and polishing template, the upper mosaic layer 2 of the double mosaic layer wax-free grinding and polishing template is provided with at least one film placement hole 1, in figure 1 Among them, the described hole 1 is a circular hole; figure 2 Among them, the sheet hole 1 is a rectangular hole; in the actual processing process, the shape of the sheet hole 1 can be processed and matched according to the shape of the material to be ground and polished; the lower mosaic layer 6 has a The same technical features of the mosaic layer 2, the wax-free grinding and polishing template of the double mosaic layer is provided with a diversion hole 9 for infiltrating the polishin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com