Harmless treatment method for reducing stainless steel leftover sludge at medium temperature

A disposal method, stainless steel technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of rising production costs, lack of competitiveness, high treatment costs, etc., and achieve low operating costs, The effect of small footprint and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

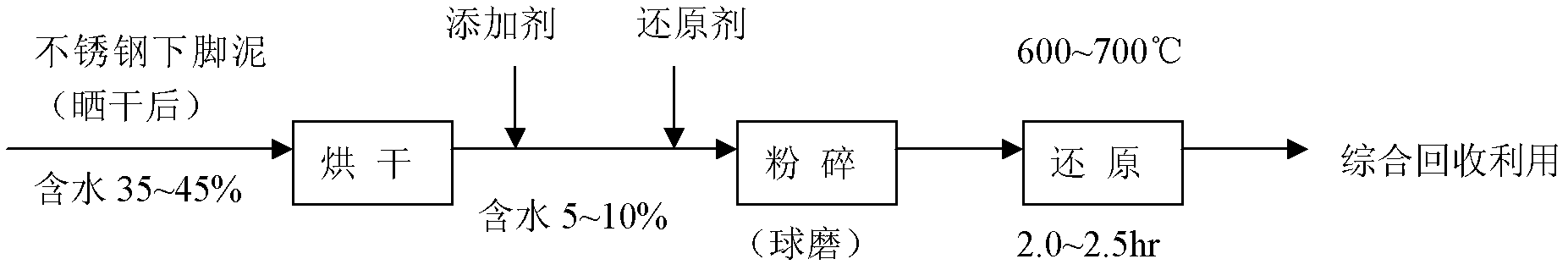

[0030] according to figure 1 In the operation method shown, the amount of 130T / day waste generated by the stainless steel production enterprise is firstly dried. After measurement, the water content is 65% just after leaving the production line, and after it reaches 40% after drying, the waste Dried in a drier until the water content of the leftover mud is 10%, respectively 5% by mass, calcium oxide and coal are mixed into the leftover mud, and stirred evenly, wherein the water-soluble pH of the leftover mud is measured as 8.2 ( According to the ratio of 1:4), put the mixed material into the muffle furnace for sintering, the sintering temperature is constant at 610°C, take out a sample every half an hour, mark them as 1, 2, 3, 4, and last for 2 hours. Use the sulfuric acid nitric acid method for extreme toxicity leaching of the samples (the identification standard for hazardous waste leaching toxicity identification GB5085.3-2007): take 30 grams each of samples 1, 2, 3, and 4,...

Embodiment 2

[0036]According to the same method of embodiment 1, the waste sludge produced by the stainless steel production enterprise is first dried in the air. After measuring, the water content just after leaving the production line is 65%. Drying in medium temperature until the moisture content of the waste sludge is 8%, respectively 6% by mass, mix calcium oxide and coal into the waste sludge, and use ball milling with pulverization to grind the average particle size of the mixed material to 0.04mm or less, stir evenly, wherein the water-soluble pH of the waste sludge is measured to be 8.2 (according to the ratio of 1:4), and then put the mixture into the muffle furnace for sintering, and the sintering temperature is kept at 680°C for 2.5 hours. The samples were taken out and measured by the method in Example 1. The treated waste sludge has met the national standard and can be discharged for treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com