Barium-calcium-zirconium-titanium leadless piezoelectric textured thick film and preparation method of thick film

A lead-free piezoelectric, zirconium-titanium technology is applied in the field of lead-free piezoelectric textured thick film and lead-free piezoelectric textured thick film texture, achieving the effects of good orientation degree, high orientation degree and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

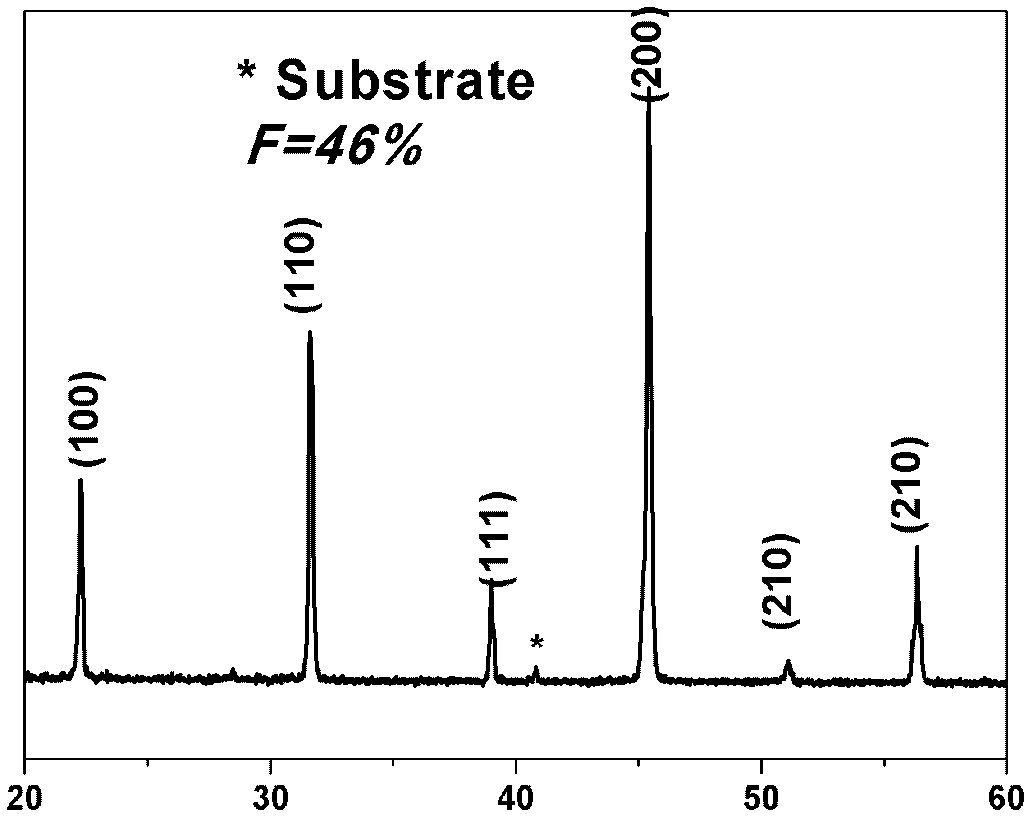

Embodiment 1

[0033] (Ba 0.8425 Ca 0.1575 )(Zr 0.105 Ti 0.895 )O 3 Preparation of base material: using BaCO 3 , CaCO 3 , ZrO 2 and TiO 2 As raw material, according to (Ba 0.8425 Ca 0.1575 )(Zr 0.105 Ti 0.895 )O 3 The stoichiometric ratio of Ba, Ca, Zr and Ti elements in the base material is obtained by a solid phase reaction method. During preparation, the raw material mixture is prepared through the steps of pre-pressing and heat treatment in sequence, wherein the process condition of pre-pressing is 2MPa constant pressure for 1 minute, and the temperature of heat treatment is 1300°C for 4 hours.

[0034] Weigh 0.5g barium titanate template and 9.5g (Ba 0.8425 Ca 0.1575 )(Zr 0.105 Ti 0.895 )O 3 Base material is placed in mortar, adds dehydrated alcohol 25ml and grinds for 3 hours, adds the binding agent that prepares and continues grinding for 1 hour, and described binding agent is the mixed solution of terpineol and ethyl cellulose, and its two The weight ratio is 10:1. ...

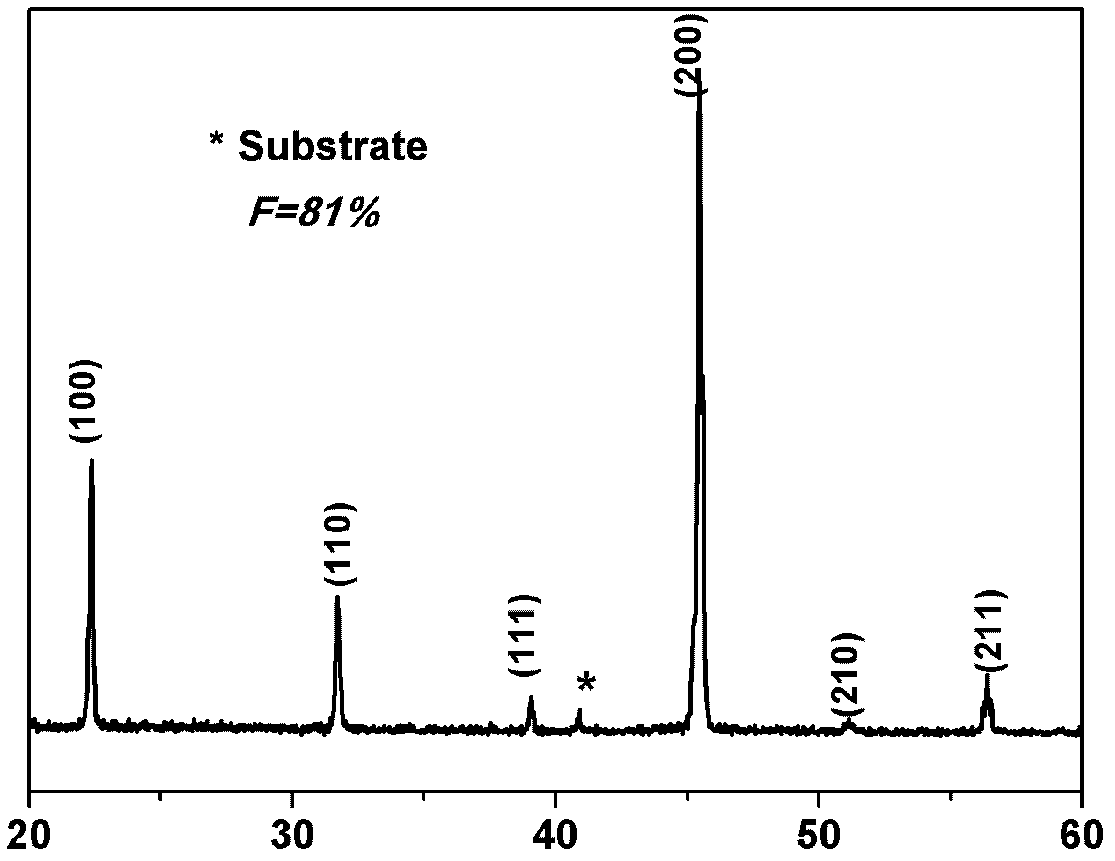

Embodiment 2

[0037] (Ba 0.82 Ca 0.18 )(Zr 0.12 Ti 0.88 )O 3 Preparation of base material: using BaCO 3 , CaCO 3 , ZrO 2 and TiO 2 As raw material, according to (Ba 0.82 Ca 0.18 )(Zr 0.12 Ti 0.88 )O 3 The stoichiometric ratio of Ba, Ca, Zr and Ti elements in the base material is obtained by a solid phase reaction method. During preparation, the raw material mixture is prepared through the steps of pre-pressing and heat treatment in sequence, wherein the process condition of pre-pressing is 2MPa constant pressure for 1 minute, and the temperature of heat treatment is 1300°C for 4 hours.

[0038] Weigh 2g barium titanate template and 8g (Ba 0.82 Ca 0.18 )(Zr 0.12 Ti 0.88 )O 3 Base material is placed in mortar, adds dehydrated alcohol 25ml and grinds for 3 hours, adds the binding agent that prepares and continues grinding for 1 hour, and described binding agent is the mixed solution of terpineol and ethyl cellulose, and its two The weight ratio is 10:1.2. Take out the prepar...

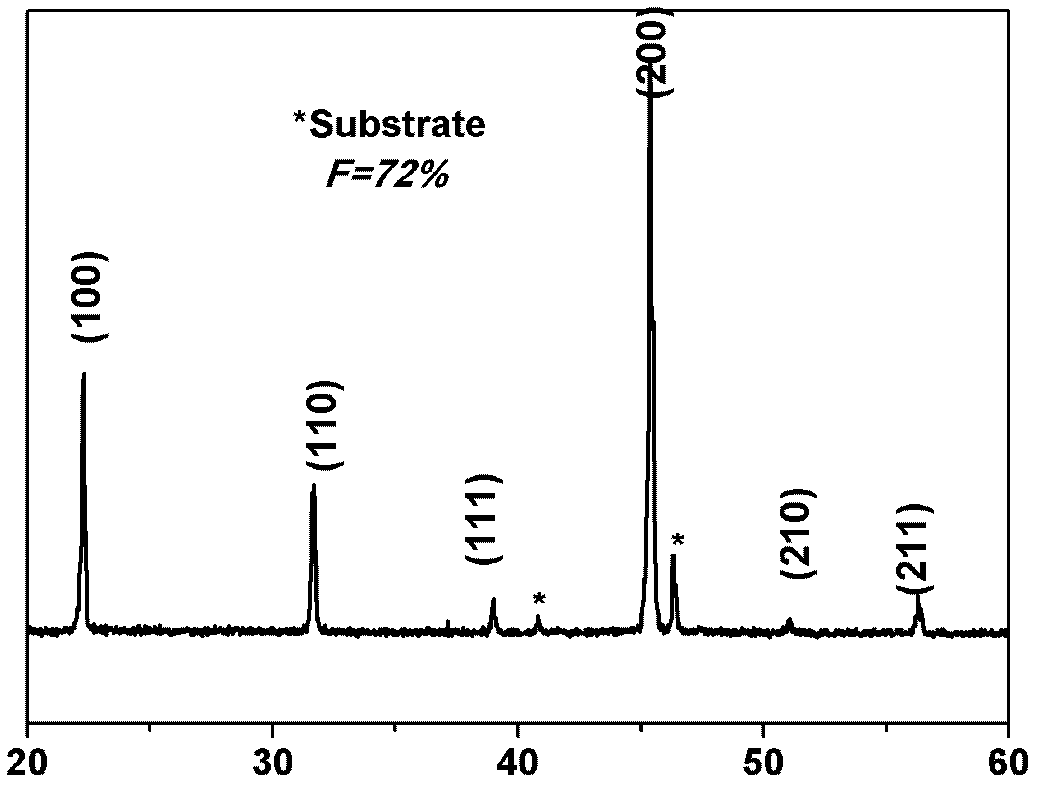

Embodiment 3

[0041] (Ba 0.805 Ca 0.195 )(Zr 0.13 Ti 0.87 )O 3 Preparation of base material: using BaCO 3 , CaCO 3 , ZrO 2 and TiO 2 As raw material, according to (Ba 0.805 Ca 0.195 )(Zr 0.13 Ti 0.87 )O 3 The stoichiometric ratio of Ba, Ca, Zr and Ti elements in the base material is obtained by a solid phase reaction method. During preparation, the raw material mixture is prepared through the steps of pre-pressing and heat treatment in sequence, wherein the process condition of pre-pressing is 2MPa constant pressure for 1 minute, and the temperature of heat treatment is 1300°C for 4 hours.

[0042] Weigh 3g barium titanate template and 7g (Ba 0.805 Ca 0.195 )(Zr 0.13 Ti 0.87 )O 3 Base material is placed in mortar, adds dehydrated alcohol 25ml and grinds for 3 hours, adds the binding agent that prepares and continues grinding for 1 hour, and described binding agent is the mixed solution of terpineol and ethyl cellulose, and its two The weight ratio is 10:1.5. Take out the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com