Production method of mixed fragrant dioctyl phthalate

A production method and technology of dicarboxylic acid, which are applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid compounds, etc., can solve problems such as failure to achieve copolymerization, reduce separation costs, improve performance, and increase market. The effect of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

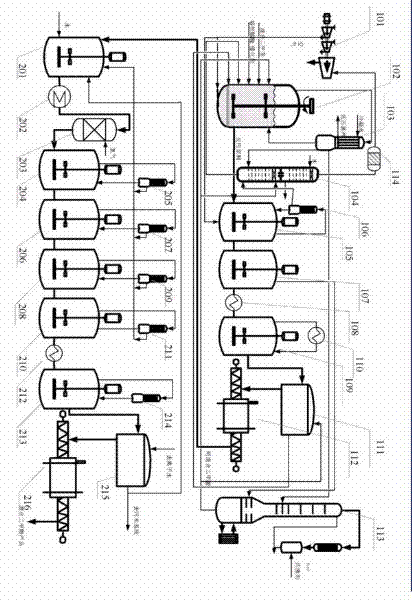

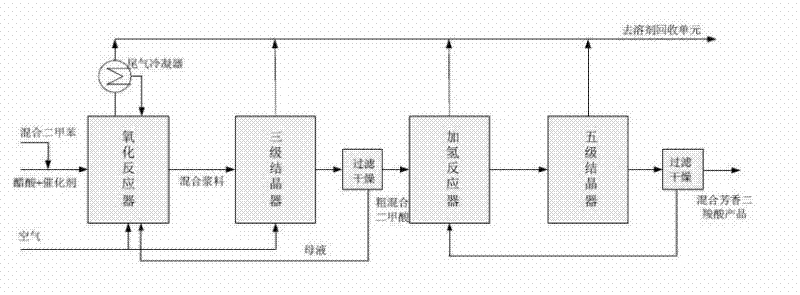

[0038] The method and equipment provided by the present invention are used to carry out the mixed aromatic dicarboxylic acid process and device design with an annual output of 600,000 tons. The annual production time is 7600 hours. The process conditions of each unit equipment are determined according to the principle of material consumption and energy consumption minimization. The energy matching among them is optimized according to the principle of system energy integration. Gained relevant process parameters are listed as follows according to the unit order:

[0039]

[0040] Under the above conditions, the indicators of the oxidation reactor output slurry are listed in Table 2.

[0041]

[0042] Note: PX—terephthalic acid, MX—isophthalic acid; 3-CBA—3-carboxybenzaldehyde, 4-CBA—4-carboxybenzaldehyde.

[0043]

[0044]

[0045]

[0046]

[0047] Through the hydrogenation reactor, the indicators of the output slurry are listed in Table 8.

[0048]

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com