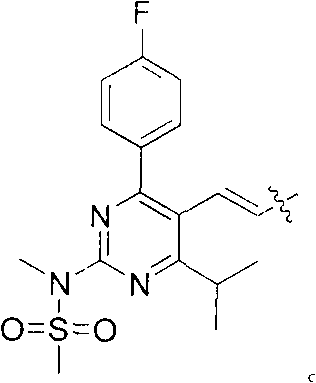

Intermediate for preparing rosuvastatin and preparation method and application thereof

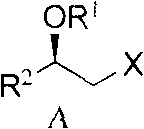

A technology for rosuvastatin and its uses, which is applied in chemical instruments and methods, compounds of elements of Group 5/15 of the periodic table, compounds of elements of Group 4/14 of the periodic table, etc., can solve serious corrosion of equipment, separation and purification Difficulty, long reaction steps and other problems, to achieve the effect of improving total yield, high reaction yield and short reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

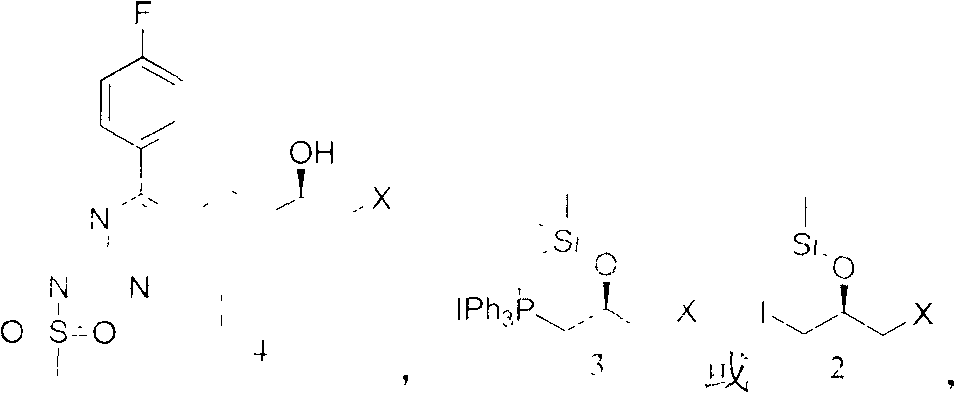

[0064] Embodiment 1: the preparation of formula 2-1 compound

[0065]

[0066] In a 500ml three-necked flask equipped with a thermometer, nitrogen atmosphere and a constant pressure dropping funnel, add iodine (66g, 260mmol), 100ml of dichloromethane, stir at room temperature, dropwise add hexamethyldisilane (40g, 280mmol), dropwise After completion, keep stirring at 15-30°C for 30 minutes, raise the temperature to 45-70°C and react for 2-4 hours until the system becomes colorless and clear, cool to -20-0°C, add R-epichlorohydrin (36g, 400 mmol) of dichloromethane solution, stirred at this temperature for 3 to 10 hours after the dropwise addition, and evaporated to dryness to obtain 110 g of the compound shown in Formula 2-1 as a slightly yellowish liquid with a yield of 98%.

[0067] 1 HNMR (400MHz, CDCl 3 ): δ=0.190 (S, 9H), δ=3.26-3.298 (dd, 1H, J=4.8, 10.4Hz), δ=3.322-3.362 (dd, 1H, J=4.8, 10.4Hz), δ=3.518 -3.601 (m, 2H), δ=3.753-3.806 (m, 1H).

[0068] MS(EI+): 292...

Embodiment 2

[0069] Embodiment 2: the preparation of formula 2-2 compound

[0070]

[0071] In a 500ml three-necked flask equipped with a thermometer, nitrogen atmosphere and a constant pressure dropping funnel, add iodine (66g, 260mmol), 100ml of dichloromethane, stir at room temperature, dropwise add hexamethyldisilane (40g, 280mmol), dropwise After completion, keep stirring at 15-30°C for 30 minutes, raise the temperature to 45-70°C and react for 2-4 hours until the system becomes colorless and clear, cool to -20-0°C, add R-epibromopropane (54g, 394mmol) of dichloromethane solution, stirred at this temperature for 2.5 to 12 hours after the dropwise addition, and evaporated to dryness to obtain 127g of the compound shown in formula 2-2 as a light yellow liquid with a yield of 96%.

[0072] MS(EI+): 338[M+], 336[M+].

Embodiment 3

[0073] Embodiment 3: the preparation of formula 3-1 compound

[0074]

[0075] Equip a 500ml single-necked bottle with a stirrer, add the compound of formula 2-1 (110g, 400mmol), triphenylphosphine (20g, 75mmol), heat up to 70-90°C and stir for 10-15 hours, cool, add 50-200ml of toluene , filtered, and the filtrate can be reused after precipitation. The filter cake was washed with 20-50 ml of toluene and dried to obtain 28 g of the compound shown in Formula 3-1 as a yellowish solid with a yield of 90%.

[0076] 1 HNMR (400MHz, DMSO): δ=0.289(S, 9H), δ=3.766-3.841(m, 2H), δ=3.847-3.941(m, 1H), δ=4.172-4.220(m, 1H), δ =4.260-4.355 (m, 1H).

[0077] MS(EI+): 554[M+].

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com