Porous and magnetic anisotropy microspheres and preparation method thereof

An anisotropic and microsphere technology, applied in the field of porous and magnetic polymer materials, can solve problems such as limited applications, inability to meet commercial production, and inability to produce in large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

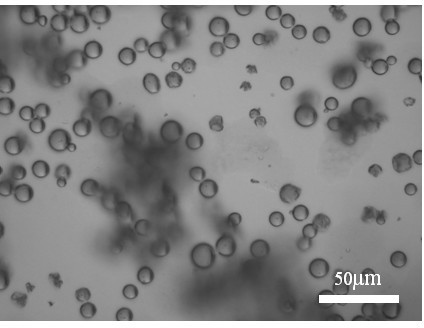

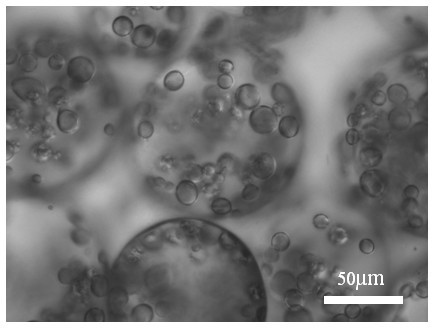

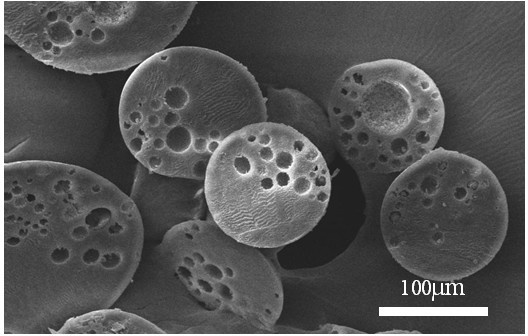

Image

Examples

Embodiment 1

[0027] Add 0.5 g of FeCl to a three-neck flask equipped with a stirrer 3 ·6H 2 O and 0.2 g FeCl 2 4H 2 O, stir to dissolve, warm up and add 2 ml NH 3 ·H 2 O, the reaction was stirred at 50 °C for 1 h. After the reaction, wash several times with ethanol and ultrapure water and prepare an aqueous dispersion of iron oxide with a concentration of 5 mg / ml; add a mixed solution of ultrapure water and ethanol with a volume ratio of 3:1 in a 100 ml beaker, Add 1 g of CTAB and 2 ml of TEA, stir evenly, then add 2 ml of TEOS at 60°C for reflux reaction for 2 h and wash to prepare an aqueous dispersion with a concentration of 1 wt%. The aqueous dispersion liquid of magnetic iron oxide in ml is the internal aqueous phase, which is added to 1 ml of the polymerizable monomer methyl methacrylate oil phase containing the initiator AIBN and 0.1 wt% hydrophobic silica, and the oil-in-water colostrum is obtained by ultrasonication ; Add 1 ml of this colostrum to 1 ml of ultrapure water con...

Embodiment 2

[0029] The preparation method of the magnetic iron oxide aqueous phase dispersion and the mesoporous silica dispersion is as in Embodiment 1. Take 1 ml of the magnetic iron oxide aqueous phase dispersion with a concentration of 5 mg / ml as the inner water phase, and add it to 5 ml of the initiator-containing In the polymerizable monomer styrene oil phase of BPO and 1 wt% hydrophobic silica, the oil-in-water colostrum was obtained by ultrasonication; then 1 ml of the colostrum was added to 5 ml of mesoporous silica containing 1 wt% ( or clay particles) in ultrapure water to prepare double Pickering emulsions; the prepared double Pickering emulsions were polymerized at 70°C for 18 h under the action of a magnetic field, washed and dried to obtain porous magnetic anisotropy Microspheres.

Embodiment 3

[0031] The preparation method of magnetic iron oxide aqueous phase dispersion liquid and mesoporous silica dispersion liquid is as embodiment one, take 1 ml of magnetic iron oxide aqueous phase dispersion liquid with a concentration of 5 mg / ml as the inner water phase, add it to 10 ml initiator-containing In the polymerizable monomer styrene oil phase of BPO and 2 wt% hydrophobic silica, the oil-in-water colostrum was obtained by ultrasonication; then 1 ml of the colostrum was added to 10 ml of mesoporous silica containing 2 wt% ( or clay particles) in ultrapure water to prepare double Pickering emulsions; the prepared double Pickering emulsions were polymerized at 80°C for 24 h under the action of a magnetic field, washed and dried to obtain porous magnetic anisotropy Microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com