Dendritic macromolecular functional titanium dioxide micro particle toughening agent and epoxy resin

A technology of titanium dioxide and micron particles, which is applied in the field of epoxy resin toughening agent, epoxy resin and its preparation, can solve problems such as unsatisfactory performance and unsatisfactory performance, and achieve the effect of increasing processing difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

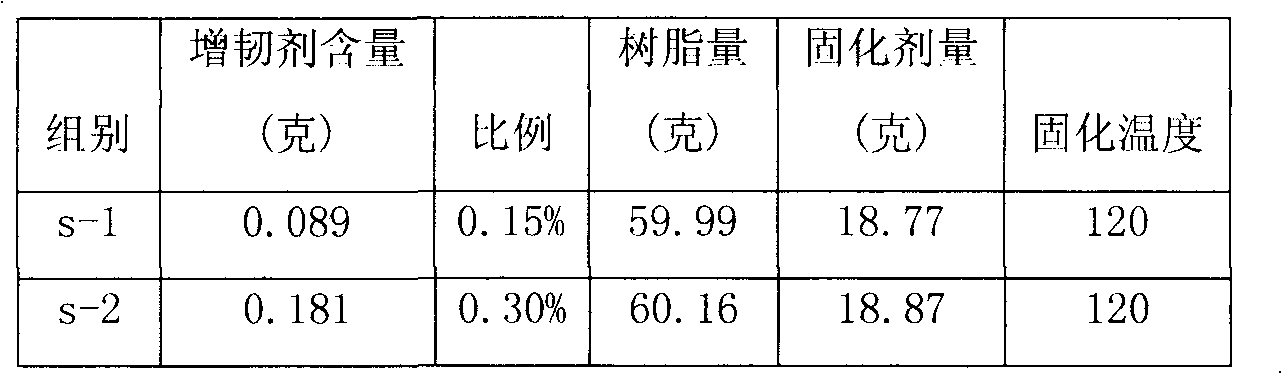

[0016] Method of Toughening Epoxy Resins with Titanium Dioxide Microparticle Tougheners Functionalized with Amino-Terminated Dendrimers,

[0017] (1) adopt one of the following methods to prepare the titanium dioxide micron particle toughening agent functionalized by amino-terminated dendrimers,

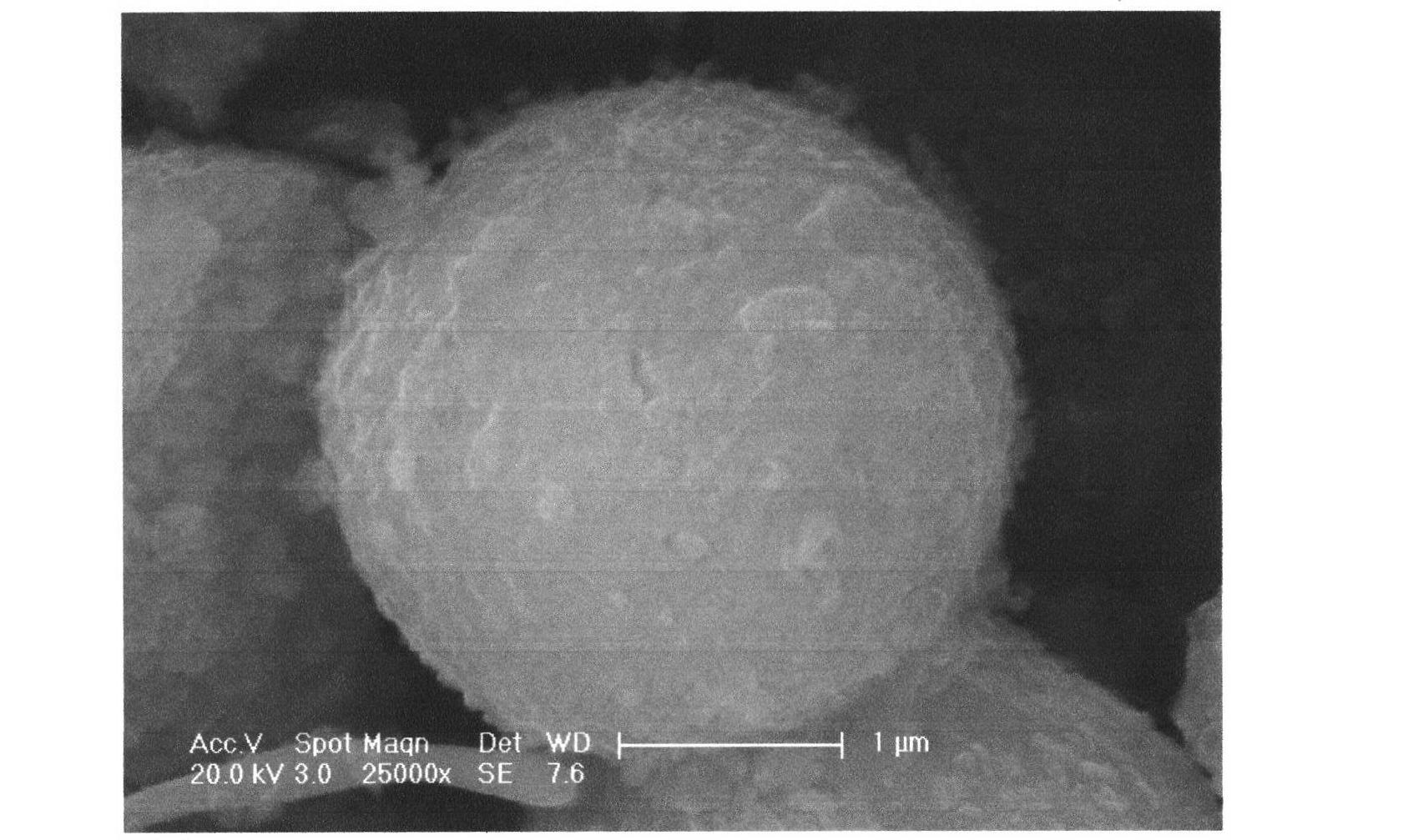

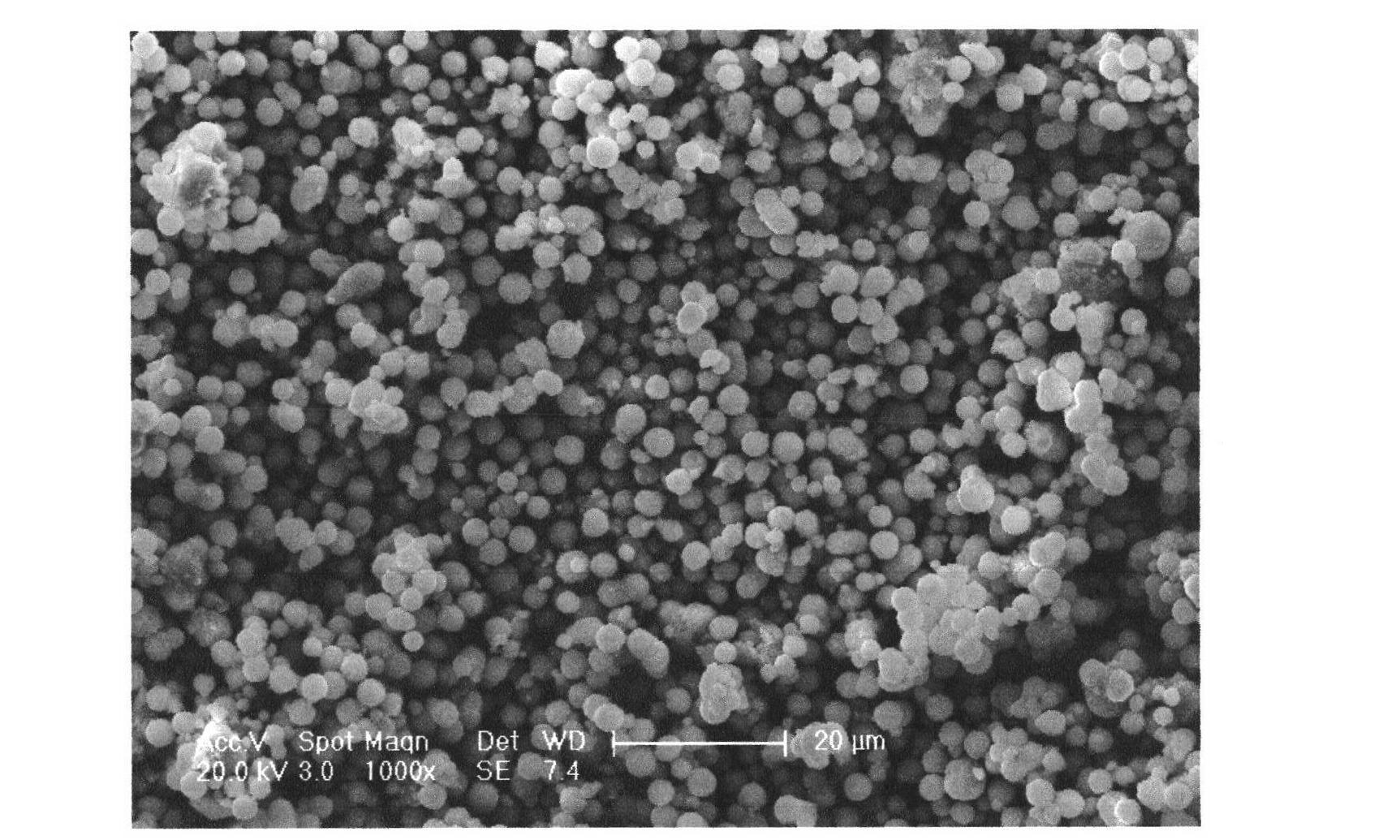

[0018] A. Disperse the amino-terminated dendrimers and titanium dioxide microparticles in organic solvents (absolute ethanol, acetone, n-hexane, cyclohexane, toluene, etc.), and add them respectively to a reaction kettle with a stirring and heating device, The titanium dioxide microparticles used here are microparticles with uniform particles obtained by hydrolysis of organic titanate. The preparation method is a method commonly used in industry to prepare titanium dioxide microparticles. The butyl orthotitanate used is Hydrolysis occurs, and the particle size distribution of titanium dioxide microparticles obtained is narrow, and its particle size can be controlled between 0.5 and 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com