Super toughness MC nylon material and preparation method thereof

A nylon and super-tough technology is applied in the field of super-tough MC nylon material and its preparation. dispersive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

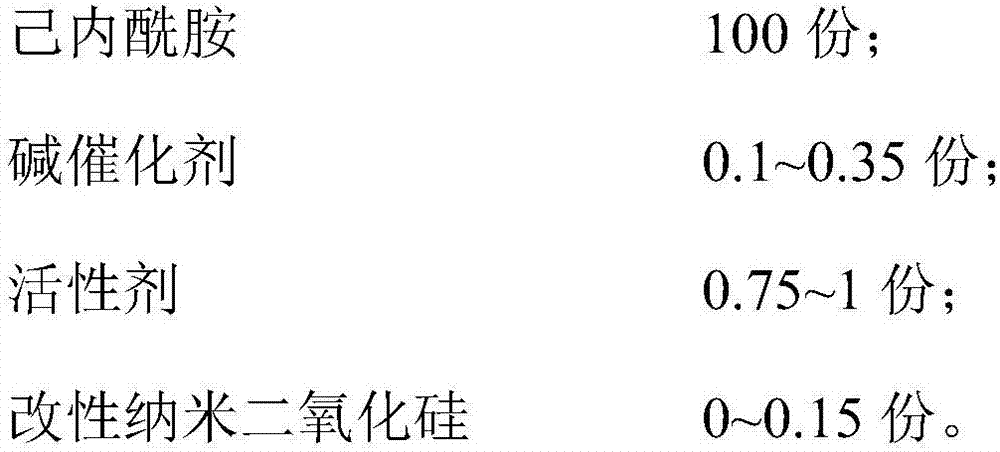

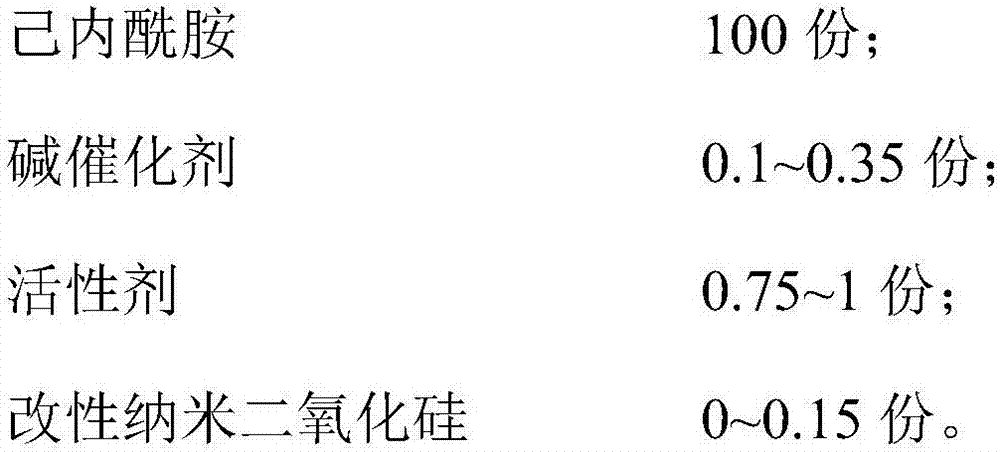

Embodiment 1

[0019] Add 100 parts of caprolactam into the Erlenmeyer flask, place it in an oil bath and raise the temperature to 90°C to heat the caprolactam to melt. Raise the temperature of the system to 120°C, vacuumize and dehydrate under the condition of magnetic stirring, release the vacuum when large bubbles appear; continue to stir and add 0.35 parts of sodium hydroxide to vacuumize, while raising the temperature of the system to 140°C, continue to stir and dehydrate, large bubbles appear, and continue to pump Vacuum for 10 minutes, release the vacuum; continue to stir, add 0.75 parts of toluene diisocyanate to obtain a prepolymerization system, cast it into a mold preheated in an oven at 180 ° C, continue heating for 2 hours, cool to room temperature, and obtain MC nylon Materials and test results are shown in Table 1.

Embodiment 2

[0021] Add 100 parts of caprolactam into the Erlenmeyer flask, place it in an oil bath and heat up to 90°C to heat the caprolactam to melt. After the caprolactam is melted, add 0.05 parts of modified nano-silica, and stir to make it completely dissolve in the caprolactam melt. . Raise the temperature of the system to 120°C, vacuumize and dehydrate under the condition of magnetic stirring, release the vacuum when large bubbles appear; continue to stir and add 0.35 parts of sodium hydroxide to vacuumize, while raising the temperature of the system to 140°C, continue to stir and dehydrate, large bubbles appear, and continue to pump Vacuum for 10 minutes, release the vacuum; continue to stir, add 0.75 parts of toluene diisocyanate to obtain a prepolymerization system, cast it into a mold preheated in an oven at 180 ° C, continue heating for 2 hours, cool to room temperature, and obtain MC nylon Materials and test results are shown in Table 1.

Embodiment 3

[0023] Add 100 parts of caprolactam into the Erlenmeyer flask, place it in an oil bath and heat up to 90°C to heat the caprolactam to melt. After the caprolactam is melted, add 0.1 part of modified nano-silica, stir to make it completely dissolve in the caprolactam melt . Raise the temperature of the system to 120°C, vacuumize and dehydrate under the condition of magnetic stirring, release the vacuum when large bubbles appear; continue to stir and add 0.35 parts of sodium hydroxide to vacuumize, while raising the temperature of the system to 140°C, continue to stir and dehydrate, large bubbles appear, and continue to pump Vacuum for 10 minutes, release the vacuum; continue to stir, add 0.75 parts of toluene diisocyanate to obtain a prepolymerization system, cast it into a mold preheated in an oven at 180 ° C, continue heating for 2 hours, cool to room temperature, and obtain MC nylon Materials and test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com