Method for manufacturing bamboo/wood-based lining plastic doors and windows

A plastic door and window and inner lining technology, which is applied in windows/doors, building components, buildings, etc., can solve the problems that are not conducive to building thermal insulation and energy saving, plastic doors and windows are easy to deform, and poor dimensional stability, and achieve low cost and high thermal insulation performance Good, the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

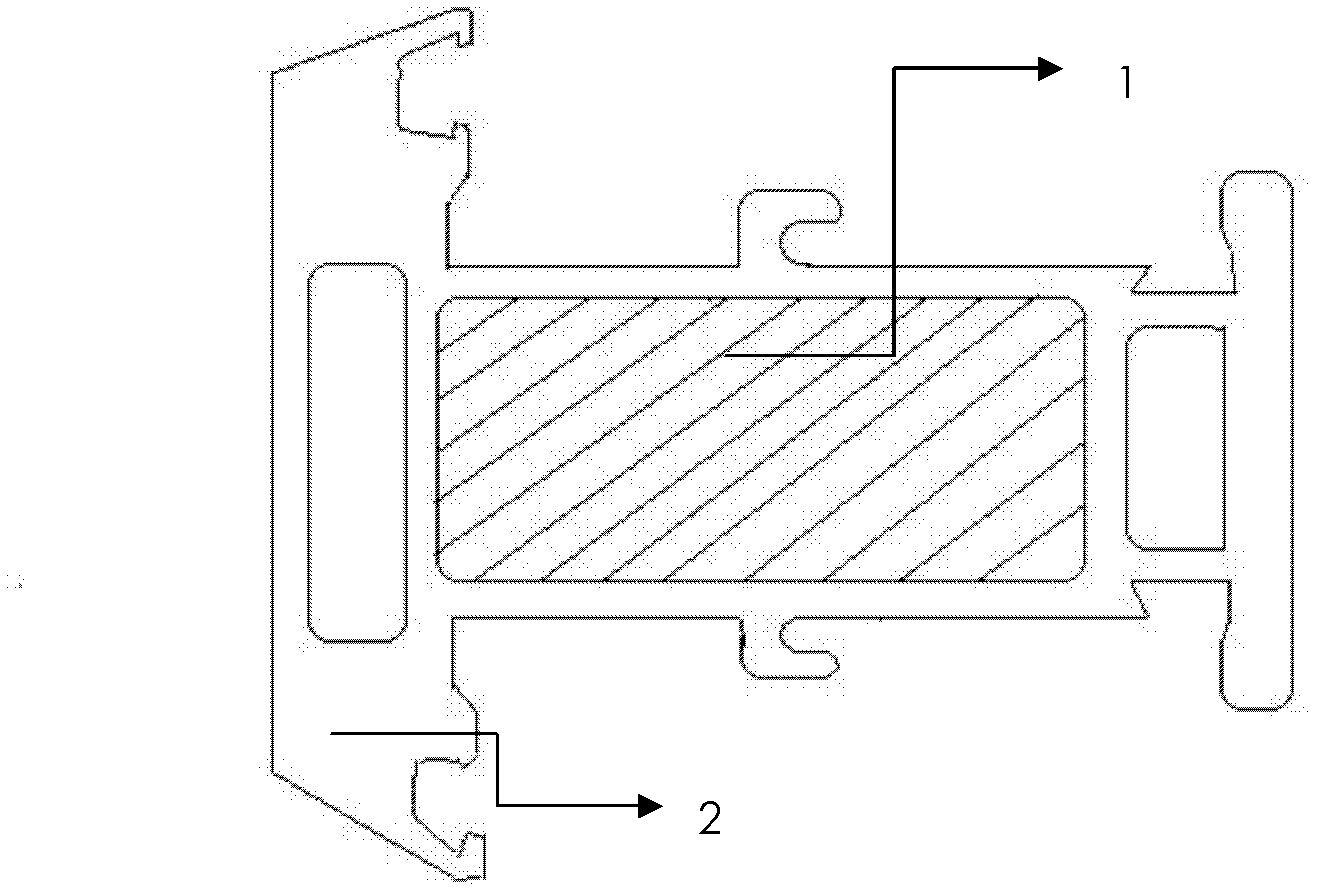

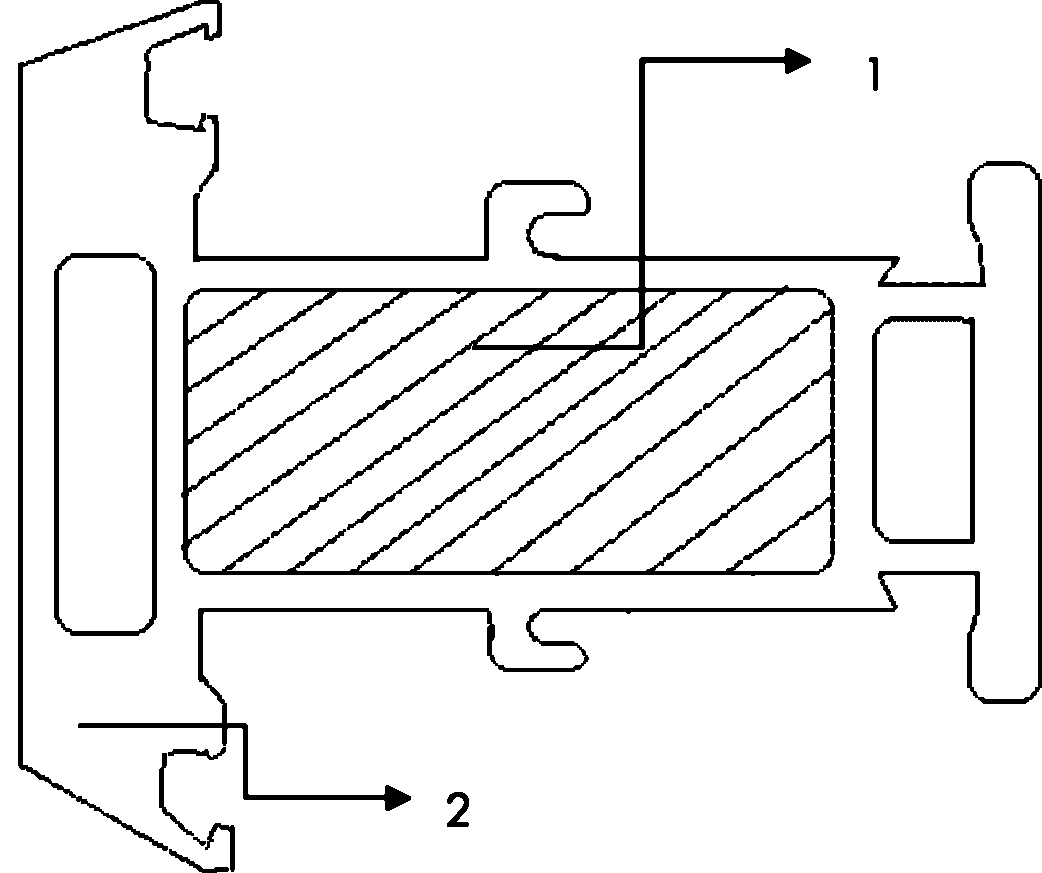

[0039] Embodiment 1, a kind of preparation method of bamboo-wood base lining plastic door and window, comprise PVC profile 2, fill lining material 1 in the cavity of PVC profile 2, the preparation method of lining material 1 is to carry out following steps successively:

[0040] 1), ingredients:

[0041] The lining material is composed of the following components by mass content: 50% recycled polypropylene (3-5mm particle size), 45% plant fiber powder (passed through a 60-mesh sieve), 1% maleic anhydride, 1% polyester Wax, 3% EPDM rubber particles (particle size 3 ~ 5mm);

[0042] Plant fiber powder selects wood fiber powder for use;

[0043] 2) Dry the plant fiber powder at 103°C for 3 hours; in the state of stirring, spray maleic anhydride into the dried plant fiber powder, after spraying, continue stirring for 10 minutes at 120°C ;

[0044] The rotational speed of the stirring was 800 rpm.

[0045] 3) Add regenerated polypropylene, polyester wax and EPDM particles to th...

Embodiment 2

[0074] Embodiment 2, a kind of preparation method of bamboo-wood base lining plastic door and window, comprise PVC profile 2, fill lining material 1 in the cavity of PVC profile 2, the preparation method of lining material 1 is as follows:

[0075] 1), ingredients:

[0076] The lining material 1 is composed of the following components by mass content: 50% recycled polyethylene (3-5mm in particle size), 45% plant fiber powder (passed through a 60-mesh sieve), 1% maleic anhydride, 1% poly Ester wax, 3% EPDM rubber particles (particle size 3 ~ 5mm);

[0077] Plant fiber powder selects bamboo fiber powder for use;

[0078] 2) Dry the plant fiber powder at 103°C for 3 hours; under stirring, spray maleic anhydride into the dried plant fiber powder, after spraying, continue stirring for 10 minutes at 120°C;

[0079] The rotational speed of the stirring was 800 rpm.

[0080] 3) Add regenerated polyethylene, polyester wax and EPDM particles to the obtained product of step 2) and put...

Embodiment 3

[0109] Embodiment 3, a kind of preparation method of bamboo-wood base lining plastic door and window, comprise PVC profile 2, fill lining material 1 in the cavity of PVC profile 2, the preparation method of lining material 1 is as follows:

[0110] 1), ingredients:

[0111] The lining material 1 is composed of the following components by mass content: 25% recycled polypropylene (3-5mm particle size), 25% recycled polyethylene (3-5mm particle size), 45% plant fiber powder (over 60 purpose sieve), 1% maleic anhydride, 1% polyester wax, 3% EPDM particles (particle size is 3-5mm);

[0112] Plant fiber powder selects wood fiber powder for use;

[0113] 2) Dry the plant fiber powder at 103°C for 3 hours; under stirring, spray maleic anhydride into the dried plant fiber powder, after spraying, continue stirring for 10 minutes at 120°C;

[0114] The rotational speed of the stirring was 800 rpm.

[0115]3) Add regenerated polypropylene, regenerated polyethylene, polyester wax and EP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com