Special strengthening, toughening and transmittance increasing master batch for ultrathin fully-biodegradable mulch film

A technology of strengthening, toughening and degrading mulch, which is applied in the field of agricultural materials, can solve the problems of decreased tensile strength and tear strength, early cracking of mulch, and high cost of mulch, so as to maintain smoothness and ensure mechanical properties and use stability, to solve the effect of poor mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

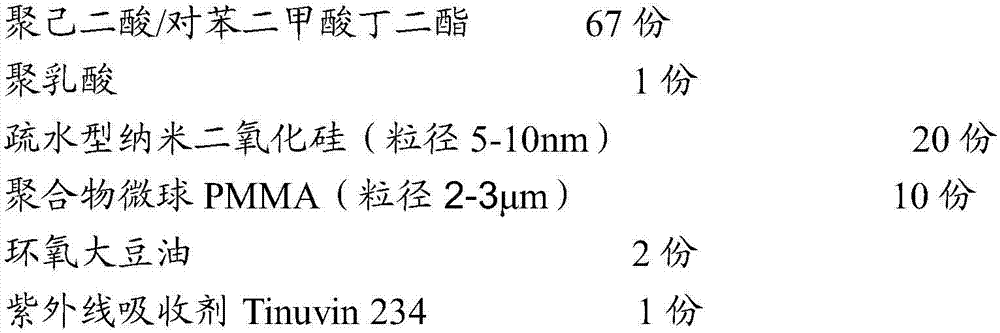

[0022] Reinforcing, toughening and anti-reflection masterbatch for ultra-thin fully biodegradable mulch film, in parts by weight, includes the following components:

[0023]

[0024] Prepared according to the following steps:

[0025] Dissolve and disperse hydrophobic nano-silica and epoxy soybean oil in carbon tetrachloride, stir evenly, distill off carbon tetrachloride to obtain mixture 1; then mix mixture 1, polyadipic acid / terephthalic acid Butylene glycol ester, polylactic acid, ultraviolet absorber Tinuvin 234, and polymer microspheres PMMA are sequentially put into a high-speed mixer for stirring at 700-1000 r / min, and mixed for 10-30 minutes to obtain a mixture 2; the mixture 2 is put into a twin-screw extruder, Extruded at 135-160°C, air-cooled and granulated to obtain reinforced, toughened, and anti-reflective masterbatches for ultra-thin fully biodegradable mulch films.

Embodiment 2

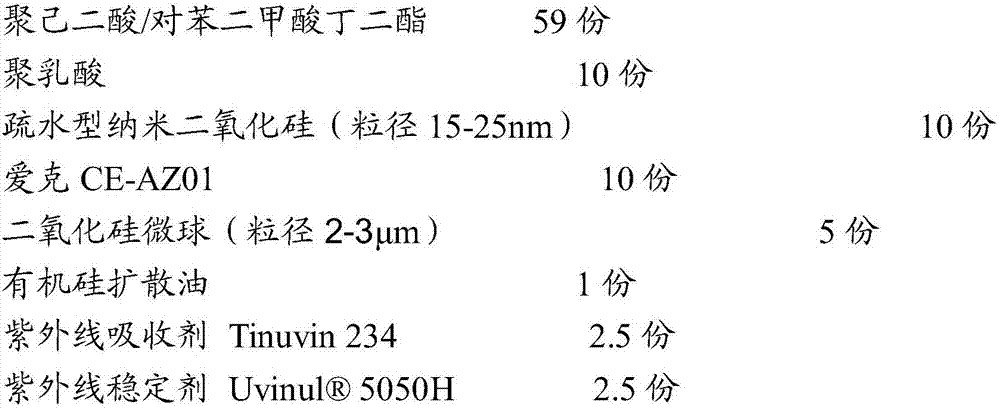

[0027] Reinforcing, toughening and anti-reflection masterbatch for ultra-thin fully biodegradable mulch film, in parts by weight, includes the following components:

[0028]

[0029] Prepared according to the following steps:

[0030] Dissolve and disperse hydrophobic nano-silica and silicone diffusion oil in carbon tetrachloride, stir evenly, distill off carbon tetrachloride to obtain mixture 1; Diester, polylactic acid, AICA CE-AZ01, UV absorber Tinuvin 234, UV stabilizer Put 5050H and silica microspheres into a high-speed mixer in turn at 700-1000r / min to stir and knead for 10-30 minutes to obtain mixture 2; put mixture 2 into a twin-screw extruder, extrude at 135-160°C, and air-cool granulate , to obtain a special reinforced, toughened and anti-permeable masterbatch for ultra-thin fully biodegradable mulch.

Embodiment 3

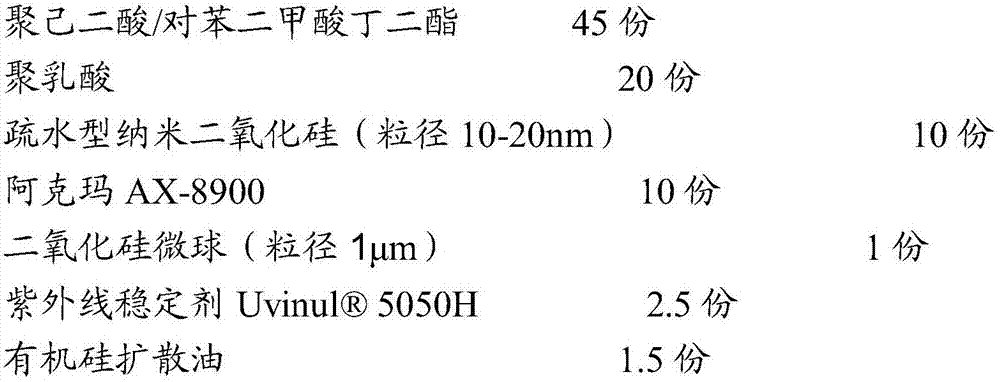

[0032] Reinforcing, toughening and anti-reflection masterbatch for ultra-thin fully biodegradable mulch, in terms of weight percentage, includes the following components:

[0033]

[0034] Prepared according to the following steps:

[0035] Dissolve and disperse hydrophobic nano-silica and silicone diffusion oil in carbon tetrachloride, stir evenly, distill off carbon tetrachloride to obtain mixture 1; Diesters, UV Stabilizers 5050H, Akema AX-8900, and silica microspheres were sequentially put into a high-speed mixer at 700-1000r / min and stirred and mixed for 10-30 minutes to obtain mixture 2; mixture 2 was put into a twin-screw extruder, Extrusion and air-cooling granulation to obtain the reinforced, toughened and anti-permeable masterbatch for ultra-thin fully biodegradable mulch film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com