Water-absorbing resin composite with durable deodorization effect and preparation method thereof

A technology of water-absorbent resin and composition, which is applied in the direction of microsphere preparation, absorbent pad, microcapsule preparation, etc., which can solve the problems of inability to achieve deodorization, inability to exert sufficient effect, and long-lasting deodorization effect, etc., and achieve good storage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

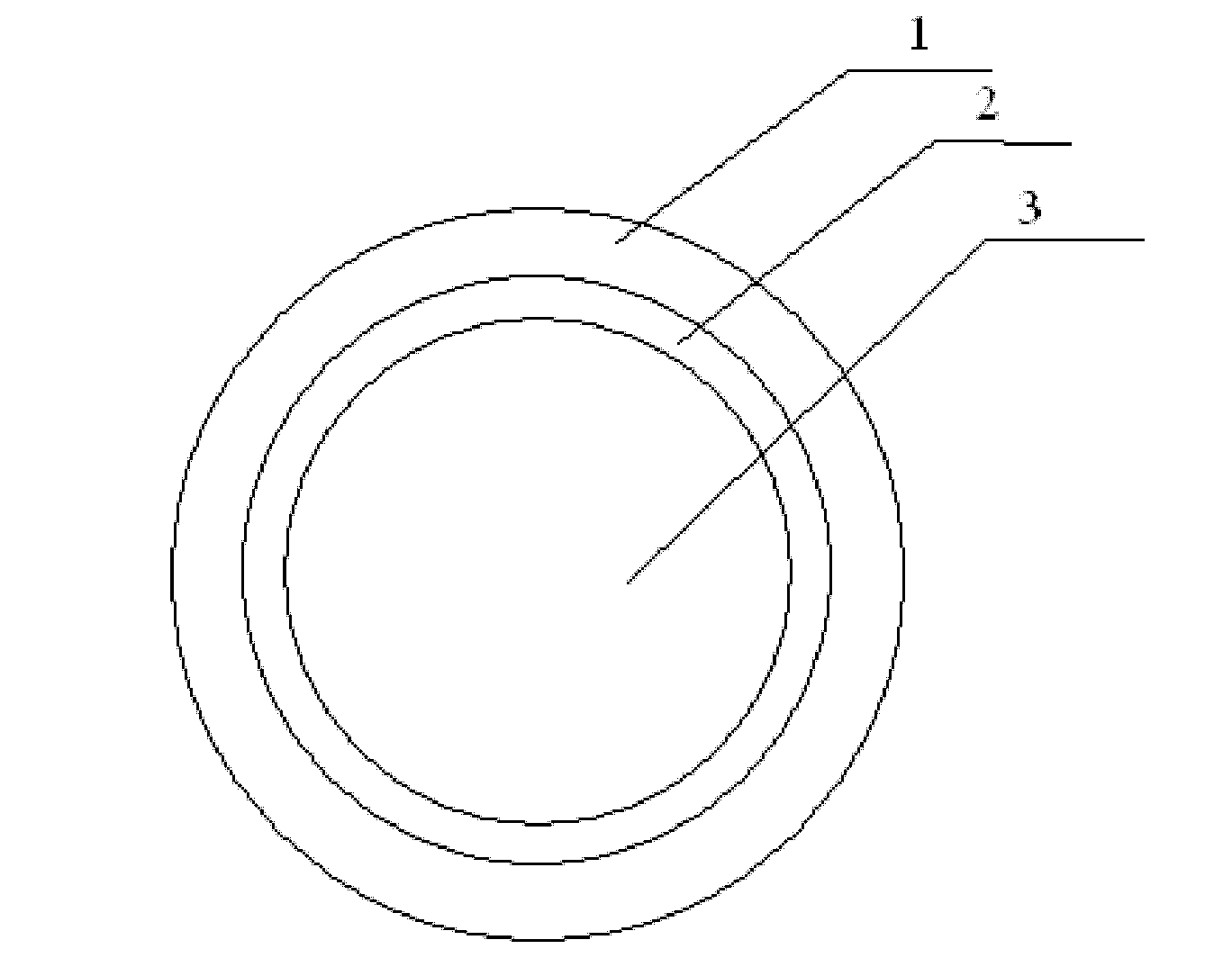

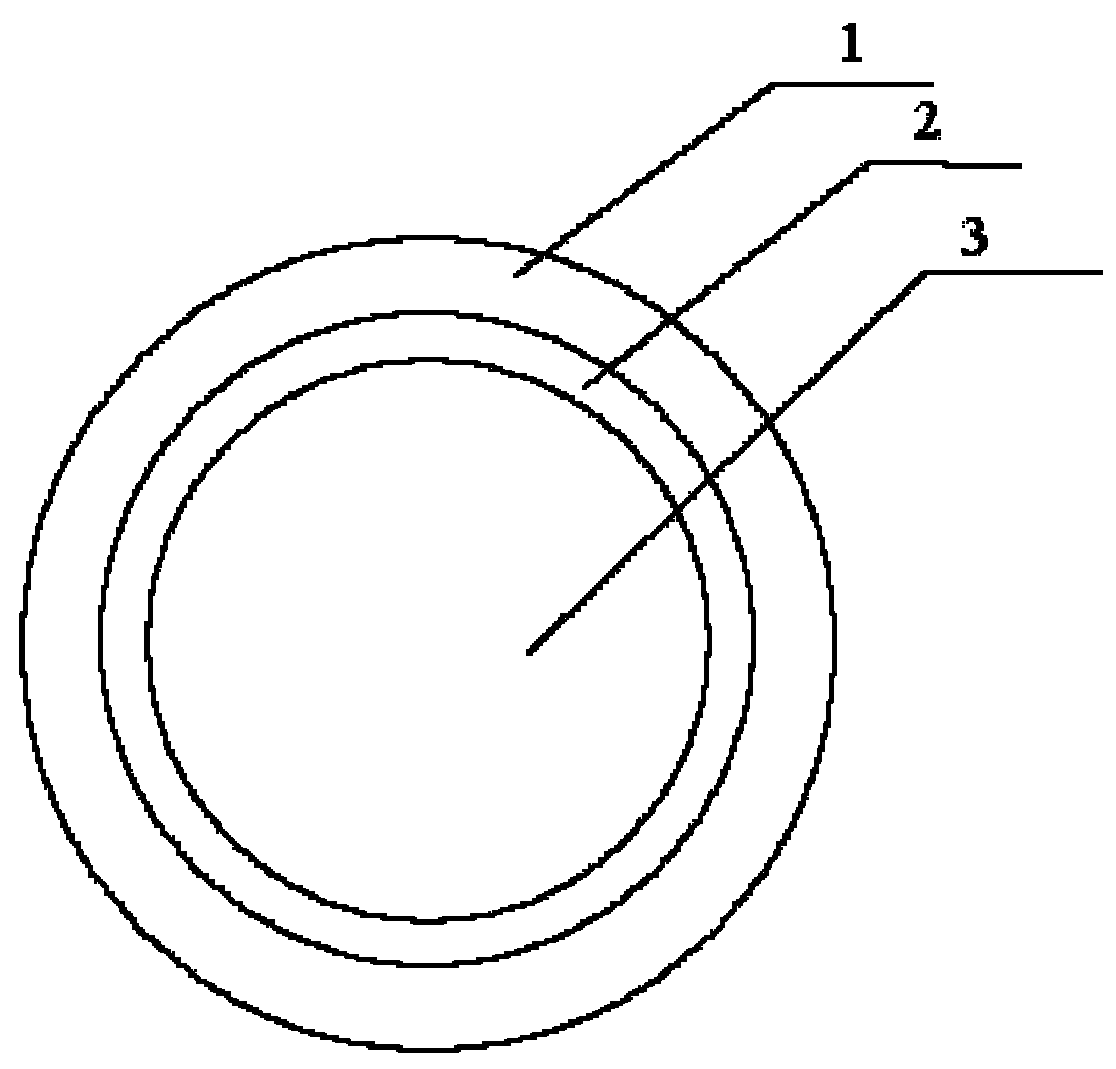

Image

Examples

Embodiment 1

[0043] (1) At room temperature, in a 250ml four-necked flask, add 100g of a concentration of 0.4wt% polymer surfactant-ethylene-maleic anhydride copolymer in water, under stirring, add 2.5g of urea, 0.25g of Ammonium chloride, 0.25g sodium chloride and 2.5% sodium chloride are used as the aqueous phase for preparing microcapsules;

[0044] The pH value of the solution was adjusted to 3.5 with 5% hydrochloric acid by weight concentration, and 20 g of lemon essence was added dropwise while stirring. After emulsification for 30 minutes, 6.4 g of formaldehyde solution with a weight concentration of 37% was added. Adjust the heating rate to 0.5°C / min, raise the temperature of the solution to 55°C, keep it warm for 3 hours, use 5% NaOH aqueous solution to adjust the pH value of the reaction solution to 7, cool and wash with water to remove the undeposited particles on the capsule core. The urea-formaldehyde particles were suction filtered and cooled at room temperature to obtain an...

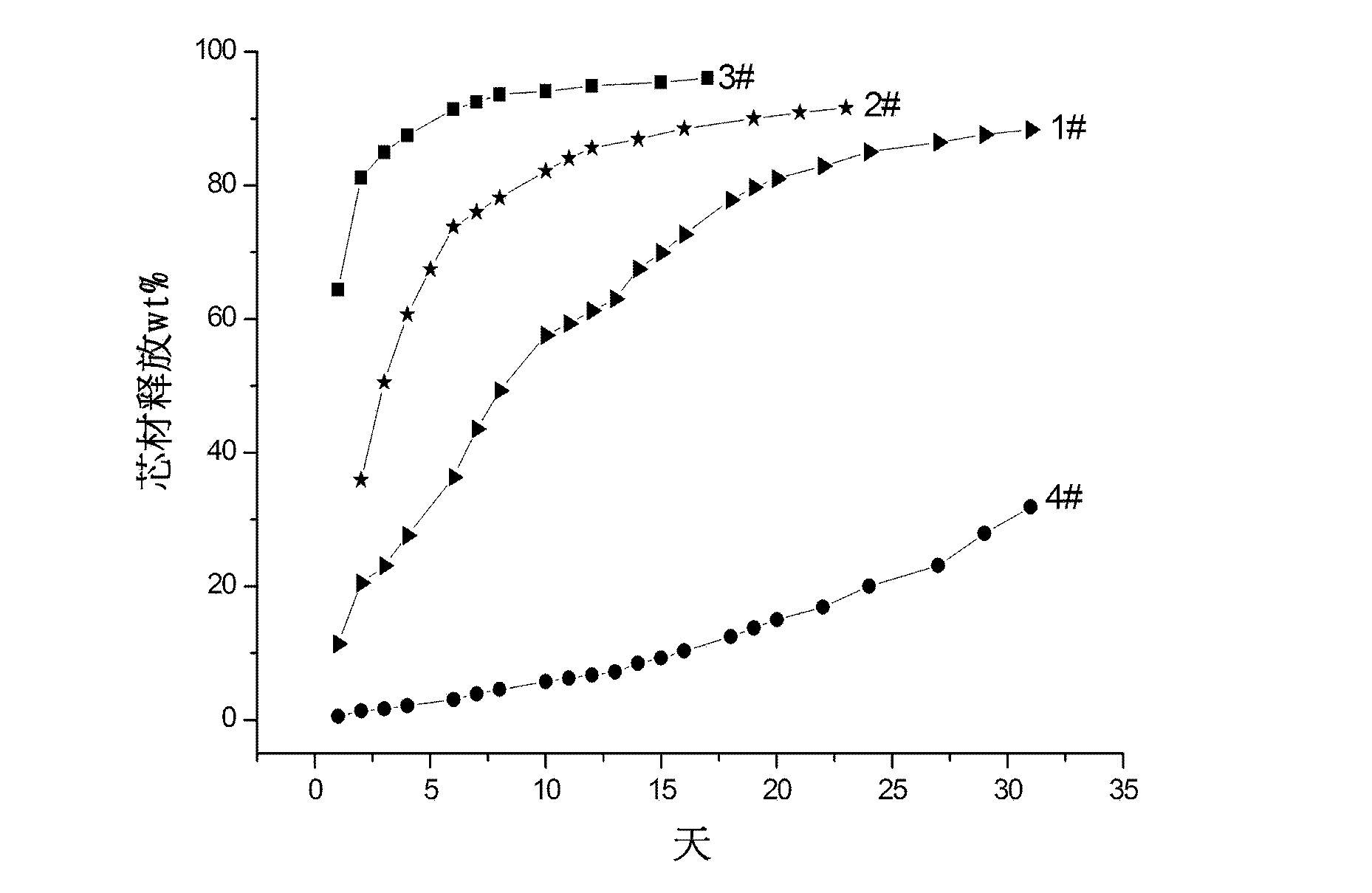

Embodiment 2

[0049] In embodiment 1, in step 1, the heating rate is adjusted to 2°C / min, and all the other are the same as in embodiment 1

Embodiment 3

[0051] In embodiment 1, do not add sodium chloride in the aqueous phase of step 1, other conditions are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap