Biomass boiler anti-coking agent with porous membrane structure and preparation method thereof

A technology of biomass boiler and anti-coking agent, which is applied in the direction of fuel additives, petroleum industry, solid fuel, etc. It can solve the problems of low utilization rate of combustion equipment, easy ash accumulation, easy slagging of biomass fuel, etc., and realize recycling , large porosity, suitable for large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

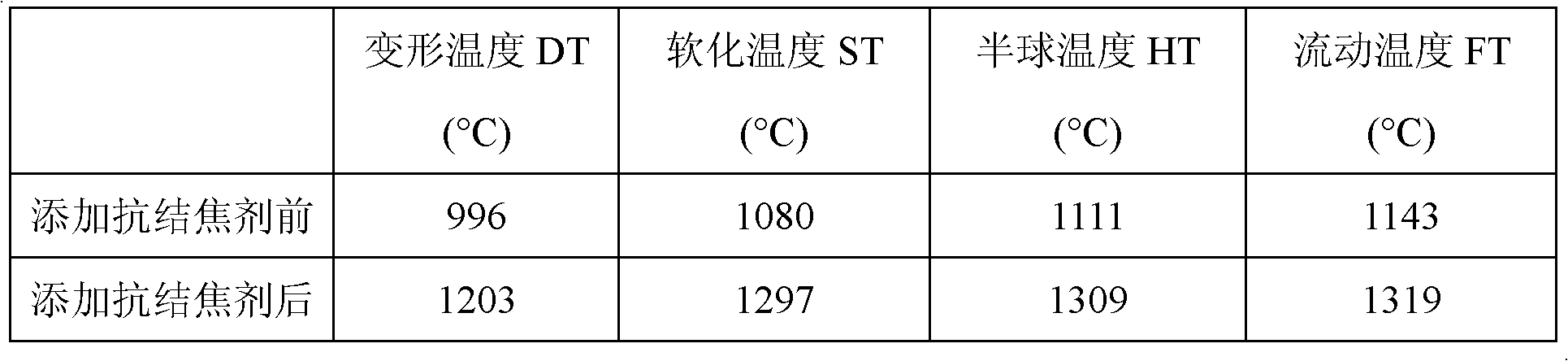

Embodiment 1

[0019] A kind of porous film structure biomass boiler anti-coking agent, this anti-coking agent is made of MgO, kaolin, active Al 2 o 3 Composed of foaming agent, the foaming agent is charcoal, MgO, kaolin and active Al 2 o 3 MgO-kaolin-active Al with MgO as anti-coking agent 2 o 3 The mass of the matrix and the components in the anti-coking agent are: 10.0g kaolin, 4.0g active Al 2 o 3 , 6.0g MgO and 20.0g charcoal.

[0020] The above-mentioned porous film structure biomass boiler anti-coking agent, its preparation method is as follows:

[0021] Step (1): 10.0g kaolin, 4.0g active Al 2 o 3 and 6.0g of MgO are ground to 0.06-0.09mm respectively, add 20.0g of charcoal with a particle size of 0.1-0.2mm, and use a semi-dry method on a press under the condition of a molding pressure of 38MPa to press it into a circular piece of φ10×5mm ;

[0022] Step (2): calcining the pressed circular tablet in a muffle furnace at 1100° C. for 4 hours;

[0023] Step (3): Grinding the ...

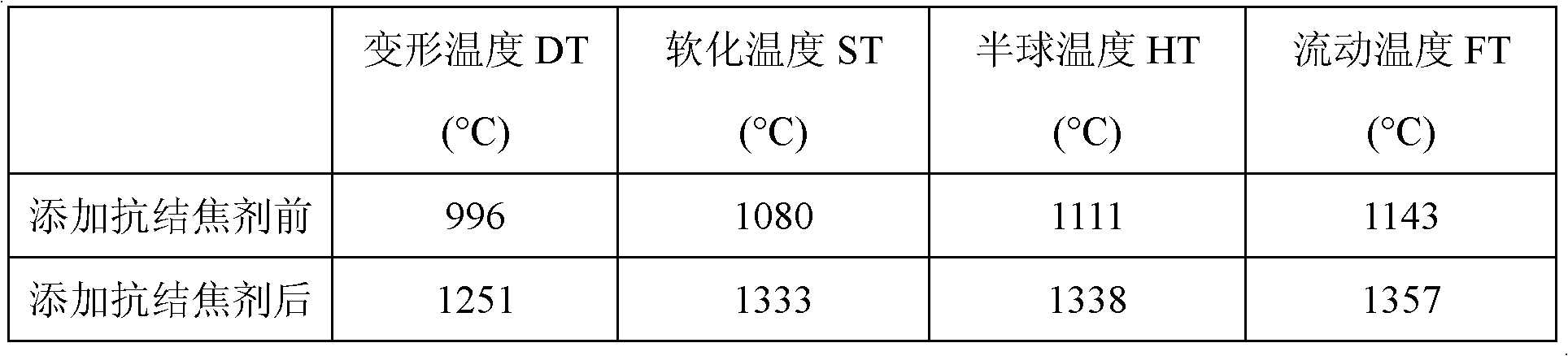

Embodiment 2

[0028] A kind of porous film structure biomass boiler anti-coking agent, this anti-coking agent is made of MgO, kaolin, active Al 2 o 3 Composed of foaming agent, the foaming agent is charcoal, MgO, kaolin and active Al 2 o 3 MgO-kaolin-active Al with MgO as anti-coking agent 2 o 3 The mass of the matrix and the components in the anti-coking agent are: 13.0g kaolin, 3.0g active Al 2 o 3 4.0g, MgO and 8.6g charcoal.

[0029] The above-mentioned porous film structure biomass boiler anti-coking agent, its preparation method is as follows:

[0030] Step (1): 13.0g kaolin, 3.0g active Al 2 o 3 and 4.0g MgO are ground to 0.06-0.09mm respectively, add 8.6g of charcoal with a particle size of 0.1-0.2mm, and use a semi-dry method on a press under the condition of a molding pressure of 39MPa to press it into a circular piece of φ10×5mm ;

[0031] Step (2): calcining the pressed circular tablet in a muffle furnace at 1150° C. for 3 hours;

[0032] Step (3): Grinding the calcin...

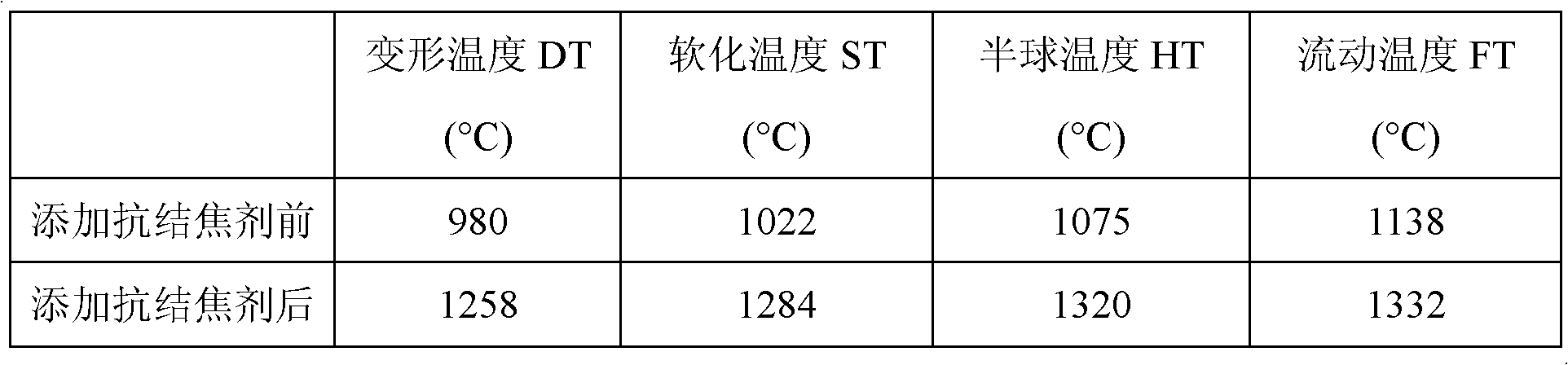

Embodiment 3

[0037] A kind of porous film structure biomass boiler anti-coking agent, this anti-coking agent is made of MgO, kaolin, active Al 2 o 3 Composed of foaming agent, the foaming agent is charcoal, MgO, kaolin and active Al 2 o 3 MgO-kaolin-active Al with MgO as anti-coking agent 2 o 3The mass of the matrix and the components in the anti-coking agent are: 5.0g kaolin, 3.0g active Al 2 o 3 , 12.0g MgO and 5.0g charcoal.

[0038] The above-mentioned porous film structure biomass boiler anti-coking agent, its preparation method is as follows:

[0039] Step (1): 5.0g kaolin, 3.0g active Al 2 o 3 and 12.0g of MgO are ground to 0.06-0.09mm respectively, add 5.0g of charcoal with a particle size of 0.1-0.2mm, and use a semi-dry method on a press under the condition of a molding pressure of 39MPa to press it into a circular piece of φ10×5mm ;

[0040] Step (2): calcining the pressed round tablet in a muffle furnace at 1200°C for 2.5 hours;

[0041] Step (3): Grinding the calcin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com