Method for preparing polyester staple fibers by using waste polyester raw material

A polyester staple fiber and polyester technology, which is applied in the field of polyester staple fiber preparation by using waste polyester raw materials, can solve the problems of low processing efficiency, molecular weight reduction, high-new material ratio, etc., so as to improve processing efficiency, avoid gel phenomenon, and ensure The effect of linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The waste polyester raw material used is waste pure polyester textile (intrinsic viscosity 0.5g / dl). Adopt the following technological conditions to carry out the preparation of regenerated polyester fiber:

[0019] (1) Raw material preparation: Wash waste polyester textiles to remove stains. The washing conditions are: synthetic detergent 5g / l, sodium tripolyphosphate 5g / l, caustic soda 0.8g / l, and temperature 90°C. The cleaned waste polyester textiles were dried in a hot air dryer for 5 hours, and after the water content dropped to 0.1%, the waste polyester raw materials were compressed with an agglomerator at 235°C in a semi-molten state to prepare spherical pellets.

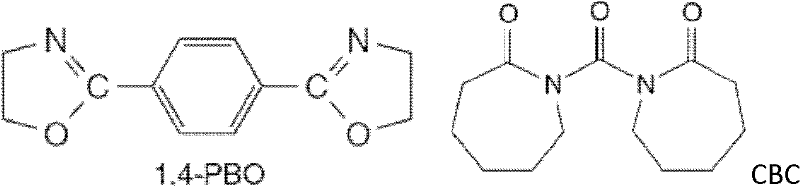

[0020] (2) Melt preparation and spinning: transfer the pellets prepared in step (1) to a drying device and dry at 120°C for 30 minutes, then dry at 140°C for 6 hours, the moisture content after drying is 30ppm, and then press the pellets 0.5% of the mass is added with a molar ratio of 1,4-phenylbisoxa...

Embodiment 2

[0023] The waste polyester raw material used is the waste silk (intrinsic viscosity 0.6g / dl) produced during the polyester spinning process. Adopt the following technological conditions to carry out the preparation of regenerated polyester fiber:

[0024] (1) Raw material preparation: Wash waste polyester textiles to remove stains. The washing conditions are: synthetic detergent 5g / l, sodium tripolyphosphate 5g / l, caustic soda 0.8g / l, and temperature 90°C. The cleaned waste polyester textiles were dried in a hot air dryer for 5 hours, and after the water content dropped to 0.1%, the waste polyester raw materials were compressed with an agglomerator at 235°C in a semi-molten state to prepare spherical pellets.

[0025] (2) Melt preparation and spinning: transfer the pellets prepared in step (1) to a drying device and dry at 140°C for 10 minutes, then dry at 170°C for 3 hours, the moisture content after drying is 40ppm, and then 3% of 1,4-phenylbisoxazoline (1,4-PBO) polyester ...

Embodiment 3

[0027] The waste polyester raw material used is waste pure polyester textile (intrinsic viscosity 0.52g / dl). Adopt the following technological conditions to carry out the preparation of regenerated polyester fiber:

[0028] (1) Raw material preparation: Wash waste polyester textiles to remove stains. The washing conditions are: synthetic detergent 5g / l, sodium tripolyphosphate 5g / l, caustic soda 0.8g / l, and temperature 90°C. The cleaned waste polyester textiles were dried in a hot air dryer for 5 hours, and after the water content dropped to 0.1%, the waste polyester raw materials were compressed with an agglomerator at 235°C in a semi-molten state to prepare spherical pellets.

[0029] (2) Melt preparation and spinning: transfer the pellets prepared in step (1) to a drying device and dry at 130°C for 20 minutes, then dry at 160°C for 4 hours, the moisture content after drying is 45ppm, and then press the pellets 2.5% of the mass is added to carbonyl bis (1,-caprolactam) (CBC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com