Preparation method of freshwater collecting fibers with transmission function and application thereof

A fiber and fresh water technology, applied in the field of chemical bionics, can solve the problems of low water collection efficiency, unsatisfactory, unenvironmental protection, etc., and achieve the effects of good outdoor stability, extended service life, and non-degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

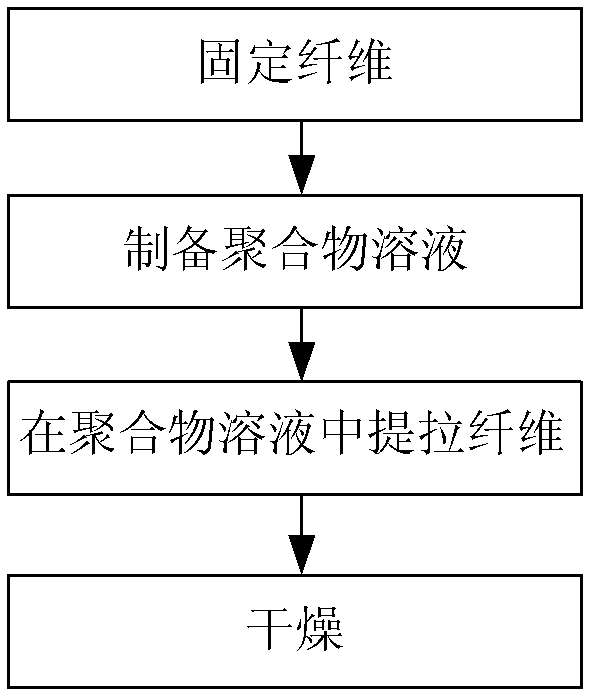

[0028] The preparation method of a kind of bionic freshwater collection fiber that the present invention proposes, such as figure 1 As shown, it specifically includes the following steps:

[0029] Step 1: Fiber Fixation:

[0030] Use colloid to fix the fiber on the bracket at a certain inclination angle, the inclination angle is preferably 10°-20°, and the average diameter of the fiber is 5-100 μm. Clean the fiber surface with acetone to remove the dust attached to the fiber surface. Fix the bracket on a pull coater (preferably a DipMaster model 50).

[0031] The fibers are synthetic fibers, man-made fibers, natural fibers or inorganic polymer fibers. When selecting synthetic fibers, nylon fibers are preferred; when man-made fibers are selected, cupro fibers are preferred; when natural fibers are selected, silk fibers are preferred; when inorganic polymer fibers are selected, carbon fibers are preferred. When it is preferably nylon fiber, the average diameter of nylon fiber...

Embodiment 1

[0043] Step 1: Fiber Fixation:

[0044] Use colloid to fix the fiber on the bracket at a certain angle, the inclination angle is 10°, the fiber is made of nylon fiber with an average diameter of 15 μm, and the surface of the fiber is cleaned with acetone to remove the dust attached to the surface of the fiber. Fasten the bracket to the pull coater - DipMaster 50 type.

[0045] Step 2: Prepare a polymer solution with a mass fraction of 5%:

[0046] 5 parts by weight of polyvinylidene fluoride PVDF was dissolved in 95 parts by weight of N,N-dimethylformamide DMF solvent, and stirred for 24 hours to make it into a clear and transparent solution to obtain a polymer solution.

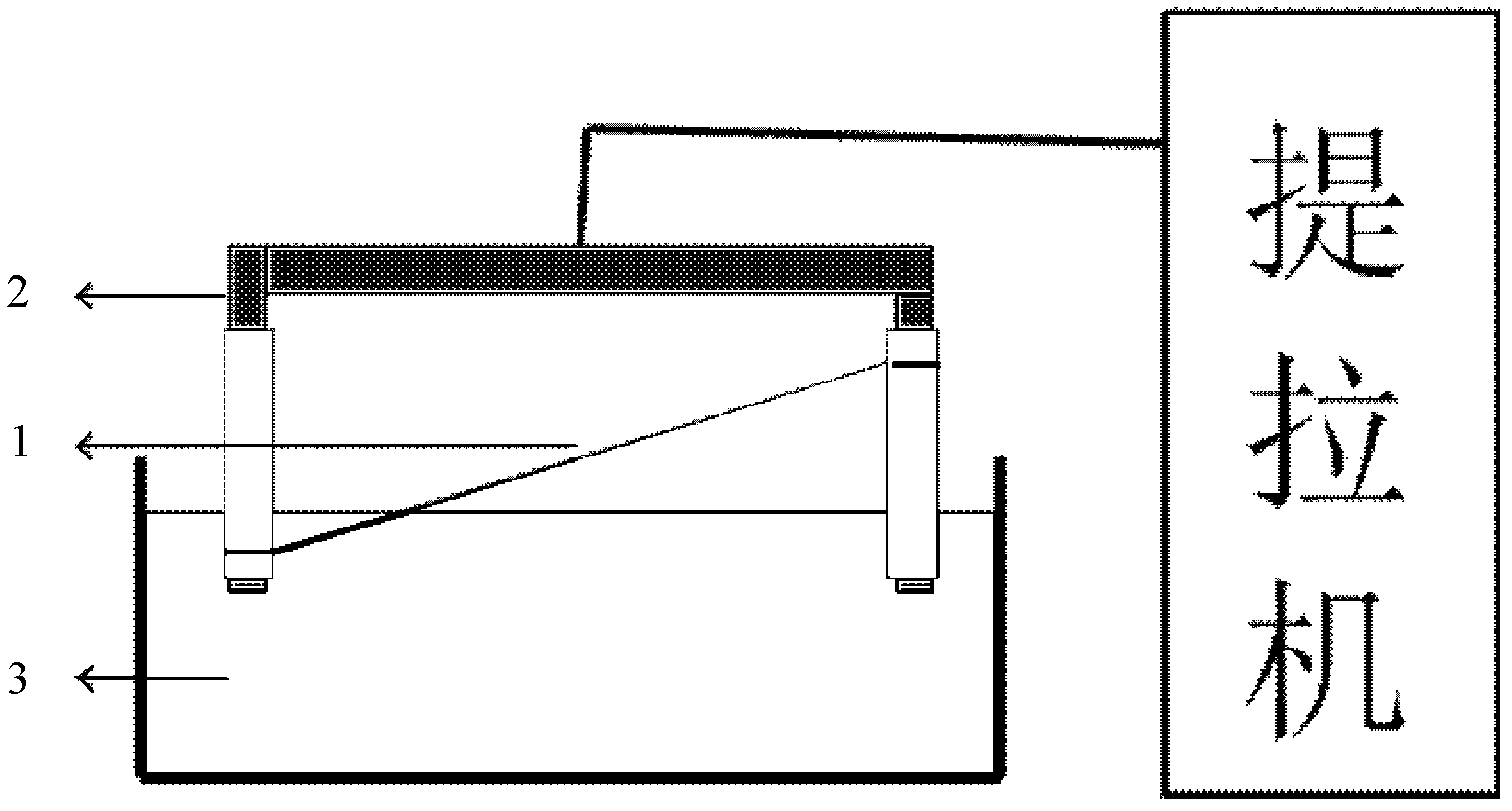

[0047] Step 3: Lifting produces protrusions arranged in order of size:

[0048] The stent fixed with the inclined fibers was completely immersed in the polymer solution for 30 s, and pulled at a speed of 150 mm / min.

[0049] Step Four: Drying:

[0050] After the pulling is completed, the fiber covered wi...

Embodiment 2

[0053] Step 1: Fiber Fixation:

[0054] Use colloid to fix the fiber on the bracket at a certain angle, the inclination angle is 20°, the fiber is carbon fiber with an average diameter of 5 μm, and the surface of the fiber is cleaned with acetone to remove the dust attached to the surface of the fiber. Fix the bracket on a pull coater (DipMaster model 50).

[0055] Step 2: Prepare a polymer solution with a mass fraction of 7%

[0056] 7 parts by weight of polyvinylidene fluoride PVDF was dissolved in 93 parts by weight of N,N-dimethylformamide DMF solvent, and stirred for 24 hours to make it into a clear and transparent solution to obtain a polymer solution.

[0057] Step 3: Lifting produces protrusions arranged in order of size:

[0058] The stent fixed with the inclined fibers was completely immersed in the polymer solution for 40 s and pulled at a speed of 175 mm / min.

[0059] Step Four: Drying:

[0060] After the pulling is completed, the fiber covered with the polymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com