Spinning oil used for easily-dyed terylene BCF (bromochlorodifluoromethane) carpet yarn

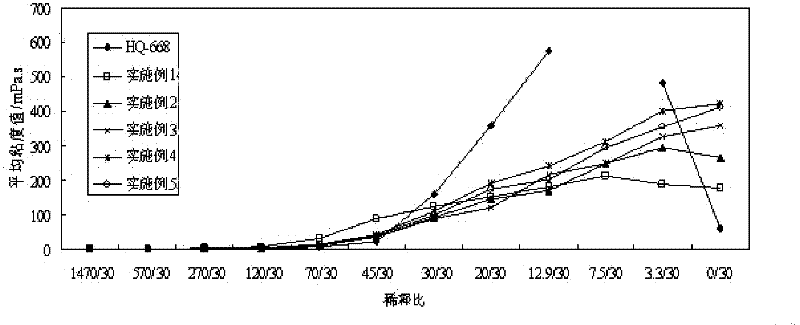

A technology for spinning oil and carpet yarn, applied in textiles, papermaking, fiber processing, etc., can solve the problems of high inversion point viscosity of oil, inability to adhere quickly and evenly, poor fiber cohesion, etc., and achieve coking residue. The effect of less, good package formation, and improved spinnability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment is composed of 50 parts by weight of each component smoothing agent, 20 parts of emulsifier, 7 sizing agents, and 2 parts of antistatic agent; wherein the smoothing agent is alkylphenol polyoxyethylene polyoxypropylene ether, and the emulsifier is poly Ethylene glycol octyl phenyl ether, the sizing agent is polyethylene glycol stearate, and the antistatic agent is octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate; mix the ingredients according to the above weight ratio , heated up to 70°C, stirred evenly at a stirring speed of 550rpm, kept at a constant temperature for 30 minutes, and then cooled down to prepare an easy-to-dye polyester BCF carpet yarn spinning oil.

Embodiment 2

[0024] This embodiment is composed of 53 parts by weight of each component smoothing agent, 23 parts of emulsifier, 9 parts of sizing agent, and 3 parts of antistatic agent; wherein the smoothing agent is polyoxyethylene, the emulsifier is n-decane, and the sizing agent is Polyethylene glycol laurate, antistatic agent is alkyl ether phosphate potassium salt; mix the ingredients according to the above weight ratio, heat up to 75°C, stir evenly at a stirring speed of 550rpm, keep the temperature for 30min, and then cool down to prepare Easy-to-dye polyester BCF carpet yarn spinning finish.

Embodiment 3

[0026] This embodiment is composed of 55 parts by weight of each component smoothing agent, 24 parts of emulsifier, 11 parts of sizing agent, and 4 parts of antistatic agent; wherein the smoothing agent is polyoxypropylene block polymer, and the emulsifier is n-decyl alcohol , The sizing agent is polyethylene glycol oleate, and the antistatic agent is ammonium alkyl ether phosphate ester. Mix the ingredients according to the above weight ratio, heat up to 80°C, stir evenly at a stirring speed of 600rpm, and cool down after 35 minutes at a constant temperature To lower the temperature, it is formulated into an easy-to-dye polyester BCF carpet yarn spinning oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com