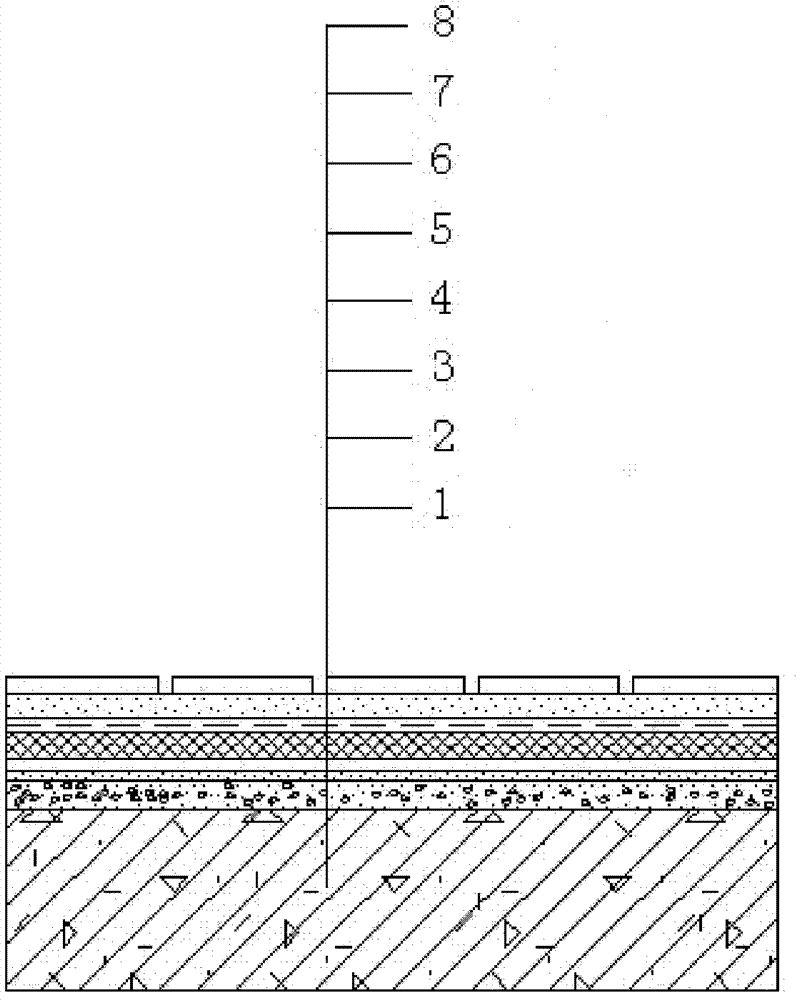

Light roofing system

A roof system and light-weight technology, which is applied to roofs, roof coverings, and roofs using tiles/slate tiles, etc., can solve the problems of heavy load-bearing structures, high maintenance costs, and high costs of houses, so as to reduce the burden on load-bearing mechanisms and avoid Water leakage phenomenon, effect of reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

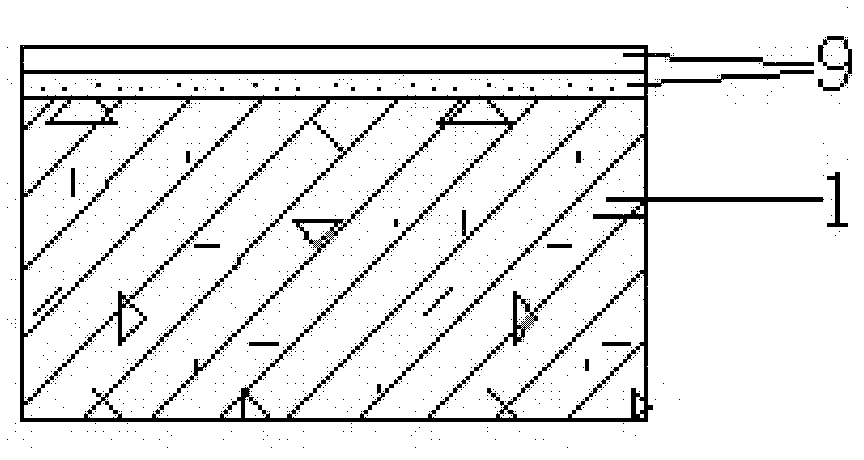

[0032] see figure 2 , the lightweight roofing system of the present embodiment comprises a substrate layer 1 and a waterproof surface layer 9, wherein the waterproof surface layer 9 comprises a waterproof coating layer made of a waterproof coating and a functional coating layer made of a functional coating, and the waterproof coating layer The waterproof coating is directly coated on the substrate layer 1, and the functional coating layer is formed by coating the functional coating on the waterproof coating layer. The substrate layer 1 can be formed of concrete or metal or polymer material or wood or roof tiles. In this embodiment, the base material layer is made of non-self-waterproof material, and its construction method is as follows:

[0033] For the substrate layer made of non-self-waterproof material, the waterproof coating can be coated twice on the substrate layer to form a waterproof coating layer, and then the functional coating can be coated on the waterproof coat...

Embodiment 2

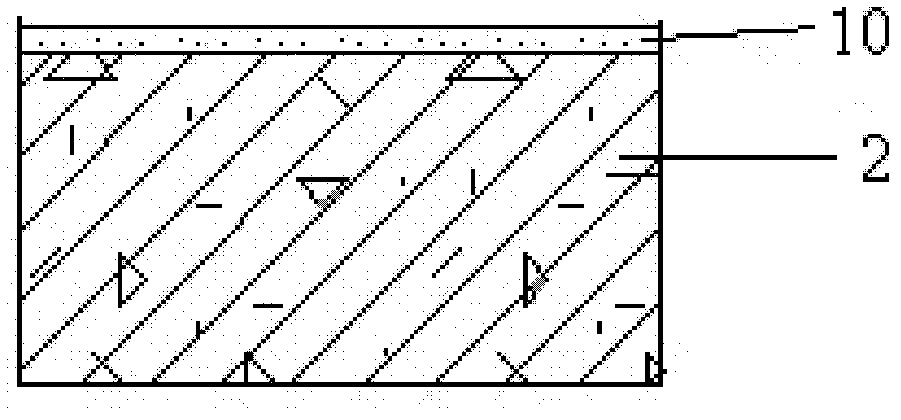

[0047] see image 3 , the light-duty roofing system in the present embodiment is made up of waterproof substrate layer 2 and surface layer 10, and surface layer 10 is made of functional paint, and waterproof substrate layer is made of self-waterproof material, and the formula and performance of functional paint It is the same as the first embodiment, and will not be repeated here.

[0048] The light roof system in the present embodiment, its construction method is as follows:

[0049] After cleaning and leveling the surface of the waterproof substrate layer, apply the functional paint evenly on the surface of the waterproof substrate layer twice, with a coating thickness of 0.3 mm to 0.5 mm.

[0050] In order to strengthen the waterproof effect of the roof, the waterproof coating can be coated twice on the waterproof base material layer, and then the functional coating can be coated on the waterproof base material layer, and evenly coated twice to obtain the lightweight roof ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com