Device for sintering magnetic material

A magnetic material and sintering device technology, applied in the direction of inorganic material magnetism, furnace type, furnace, etc., can solve the problems of reduced splicing performance, inconsistent crystal development, cracking, etc., achieve uniform temperature distribution, reduce damage, and prolong service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

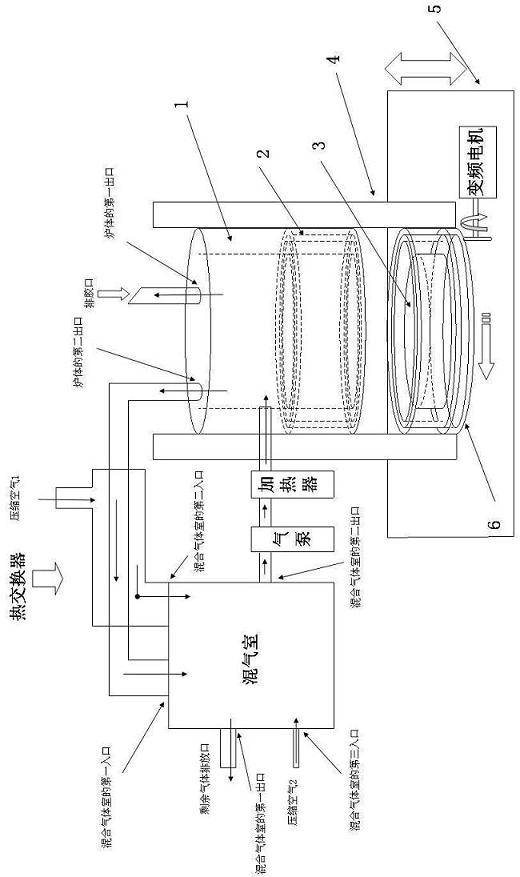

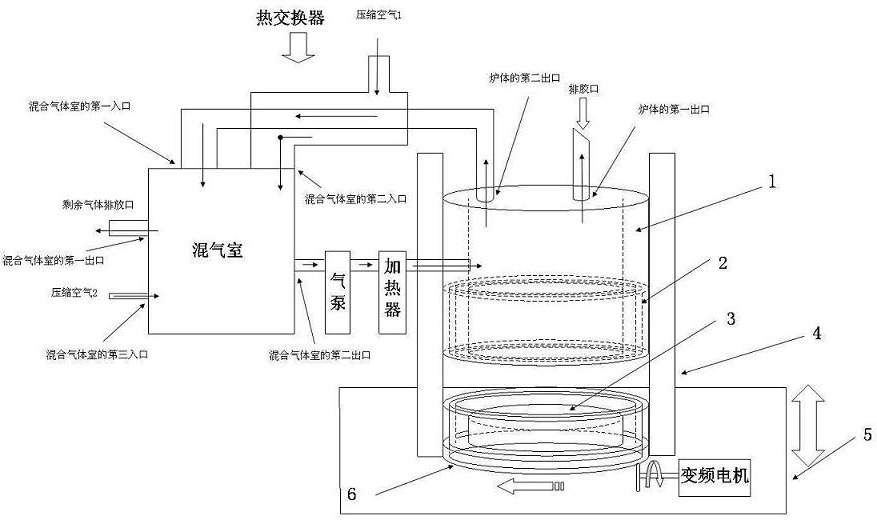

[0018] Example 1: Control figure 1

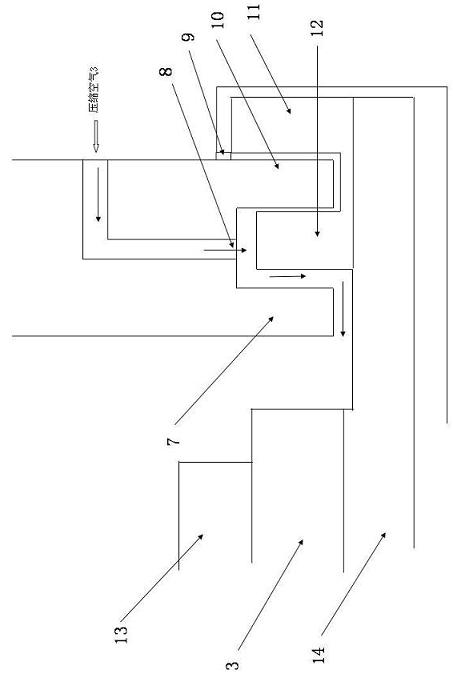

[0019] During sintering, first use a level to correct the sintered ferrite core blank placement platform 3, and make sure that the tolerance is within the range allowed by the process. Place the soft ferrite with huge volume and special shape that needs to be sintered on the sintered ferrite core blank placing platform 3; Close to form the air curtain temperature insulation device; then start the frequency conversion motor and adjust the speed of the frequency conversion motor, so that the bottom of the furnace starts to rotate at the speed required by the process. Open the air curtain temperature insulation device, use the air pressure 0.1~1Kpa higher than the sintering kiln body 1 to form the air curtain, and use a small amount of air to prevent the high-heat air from passing through the heat-resistant rubber sealing ring 9, so as to prevent high heat from affecting the auxiliary equipment and workshop personnel. coming damage.

[0020...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com